Continuous chemical solid waste anaerobic carbonizing furnace

An oxygen-free carbonization technology for solid waste, applied in fixed carbonization furnaces, gasification processes, gasification device feeding tools, etc., can solve the problems of chemical solid wastes such as weak self-degradation ability, long-term residence, and environmental pollution , to achieve the effects of low noise, strong continuous production and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

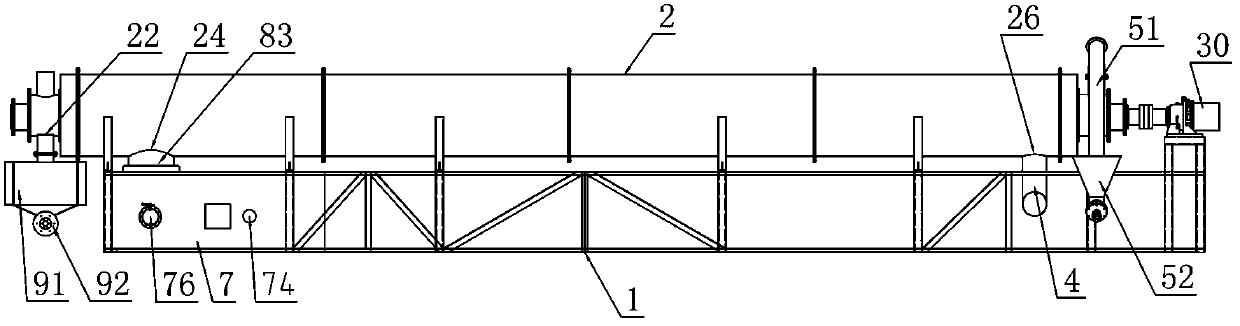

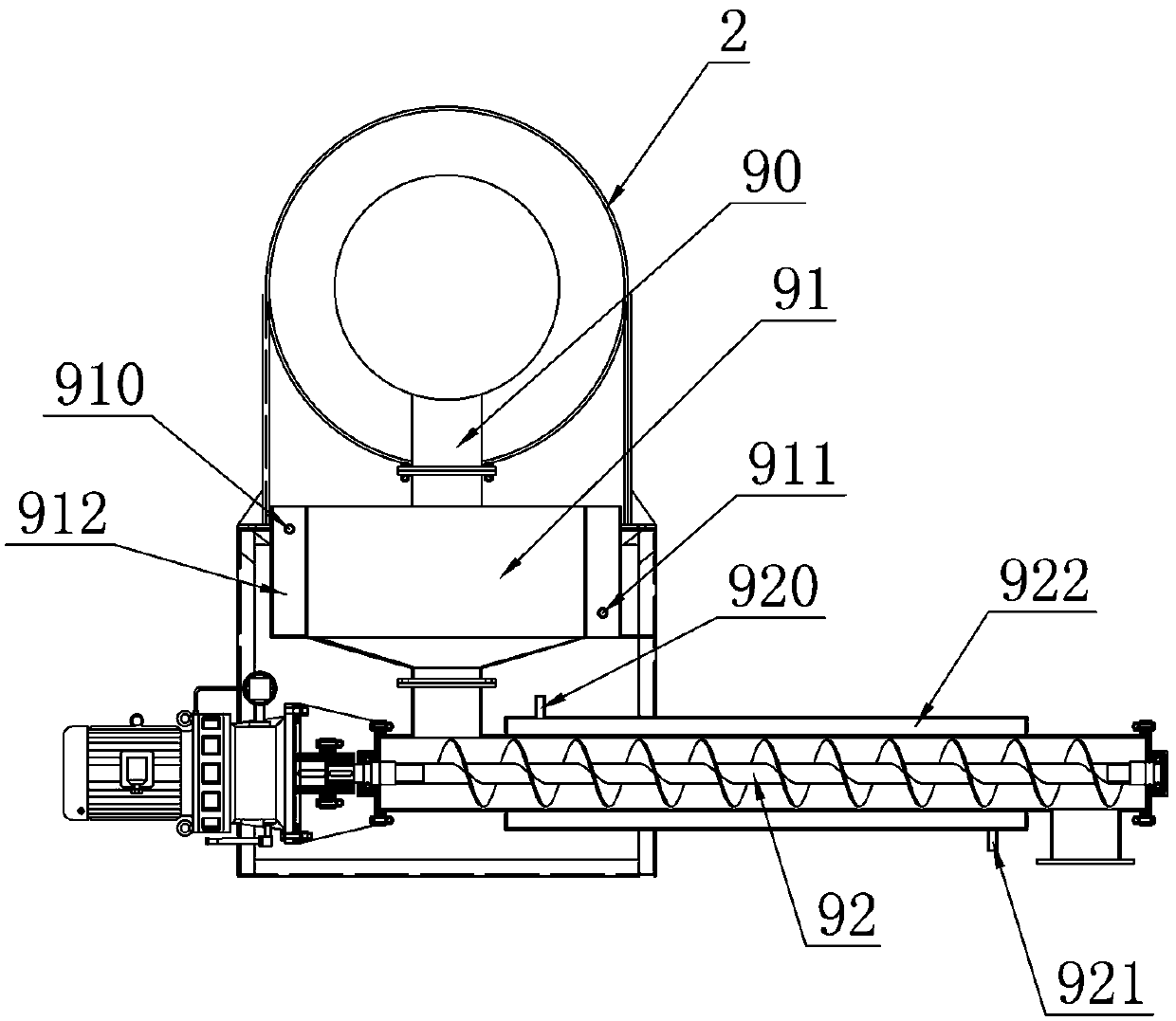

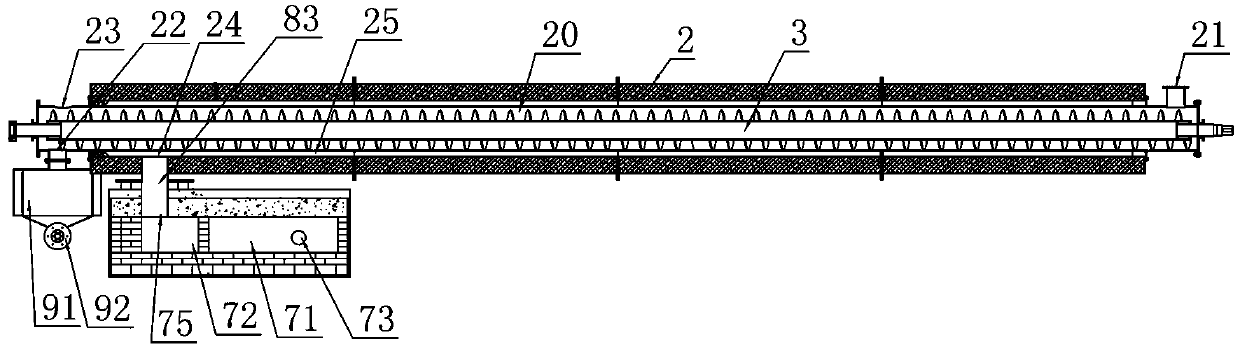

[0023] The raw materials used in the continuous anaerobic carbonization furnace for chemical solid waste are generally powdery or fine granular chemical solid waste. like figure 1 , figure 2 and image 3 As shown, the continuous anaerobic carbonization furnace for chemical solid waste described in this embodiment includes: a fixed frame 1 and a furnace body 2 with a furnace chamber 20, the furnace body 2 is horizontally arranged on the fixed frame 1, and the furnace body One end of 2 is provided with a material feed port 21, the material feed port 21 is located at the upper part of the furnace wall and the material feed port 21 is connected with the furnace cavity 20, and the material feed port 21 is sealed and connected with the feeding device. The other end of the furnace body 2 is provided with a sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com