Multi-size chip based COB automatic film sticking machine matched with multiple diaphragms

A multi-size, lamination machine technology, applied in the lamination device, control lamination, lamination and other directions, can solve the work efficiency, processing accuracy and reliability unsatisfactory, difficult to meet the efficiency requirements of chip processing of different sizes, film lamination Quality is difficult to guarantee and other issues, to achieve the effect of reducing complexity, compensating for angle error, and improving the accuracy of film sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

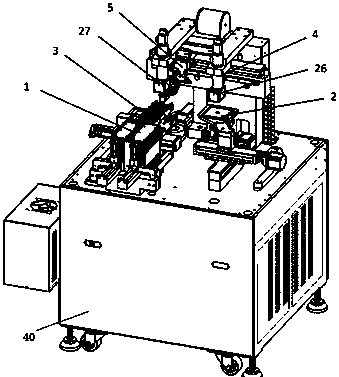

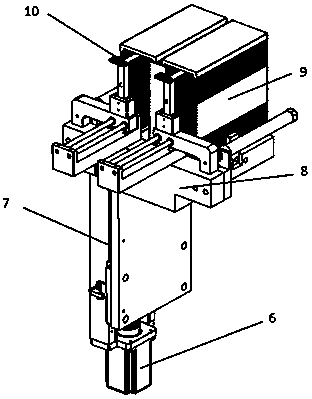

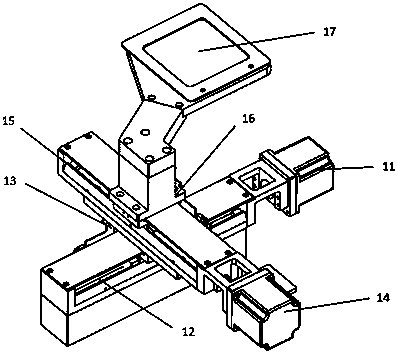

[0023] as attached Figure 1-5 As shown, the present invention discloses a COB automatic film laminating machine based on multi-size chips and multi-diaphragm matching, including a chassis, and the chassis is provided with a feeding mechanism 1, a fixture table 3, a crystal source table 2, a lens assembly 4 and Film sticking mechanism 5, the fixture table is set at the discharge end of the feeding mechanism, the crystal source table and the fixture table are arranged side by side, and there are two lens assemblies, one of which is set above the fixture table, and the other lens assembly is set on the crystal source Above the table, the film sticking mechanism is installed above the crystal source table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com