Manipulator clamping jaw mechanism used for blow molding disc

A manipulator and gripper technology, applied in the field of manipulator gripper mechanism, can solve the problems of high maintenance cost of two sets of grippers, reduced space utilization, and high design cost, and achieves easy guarantee of machining accuracy, simple operation and low design cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

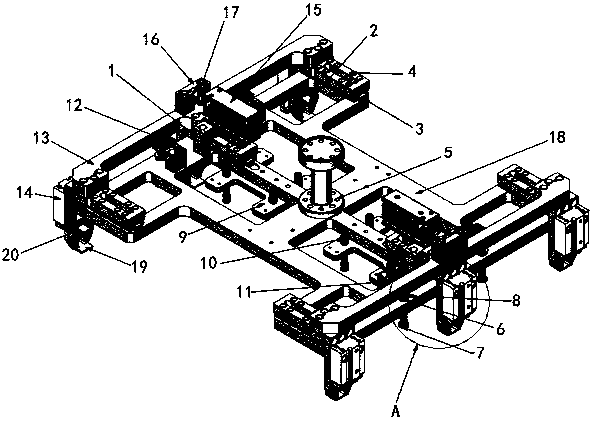

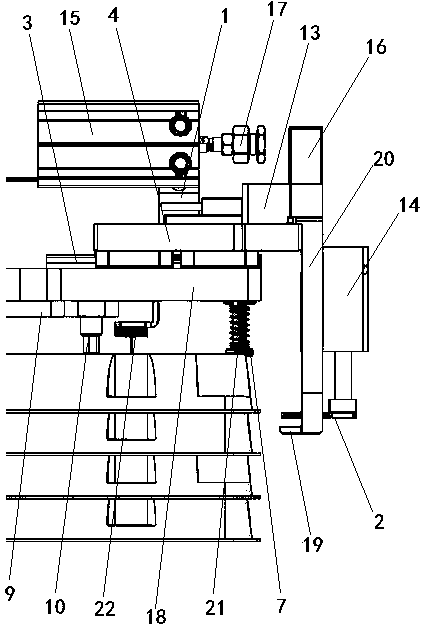

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

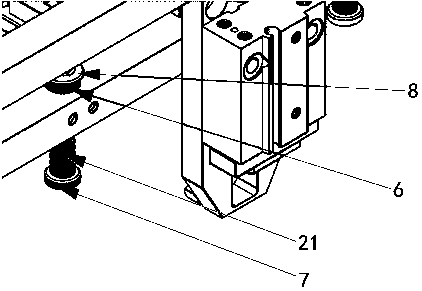

[0022] see Figure 1-3 As shown, a manipulator jaw mechanism for blow molding discs includes a left-right symmetrical base plate 18, the center point of the upper surface of the base plate 18 is provided with a manipulator flange connector 5, and the lower surface of the base plate 18 is Two symmetrically distributed suction nozzle fixing plates 9 are arranged in the middle, and a vertically downward product suction nozzle 10 is respectively arranged on the four top corners of each said suction nozzle fixing plate 9; The front, middle and rear parts of the two ends are respectively provided with a linear slide rail 3, and each of the linear slide rails 3 is provided with a movable slide rail connection block 4, and the three slide rails at the same end are connected A jaw connecting arm 13 is jointly arranged on the block 4, and a j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com