3D printing grinding wheel with cooling channels, laser 3D printer and preparation method of 3D printing grinding wheel

A 3D printer, 3D printing technology, used in bonding grinding wheels, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as poor cooling performance and easy burns on the surface of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

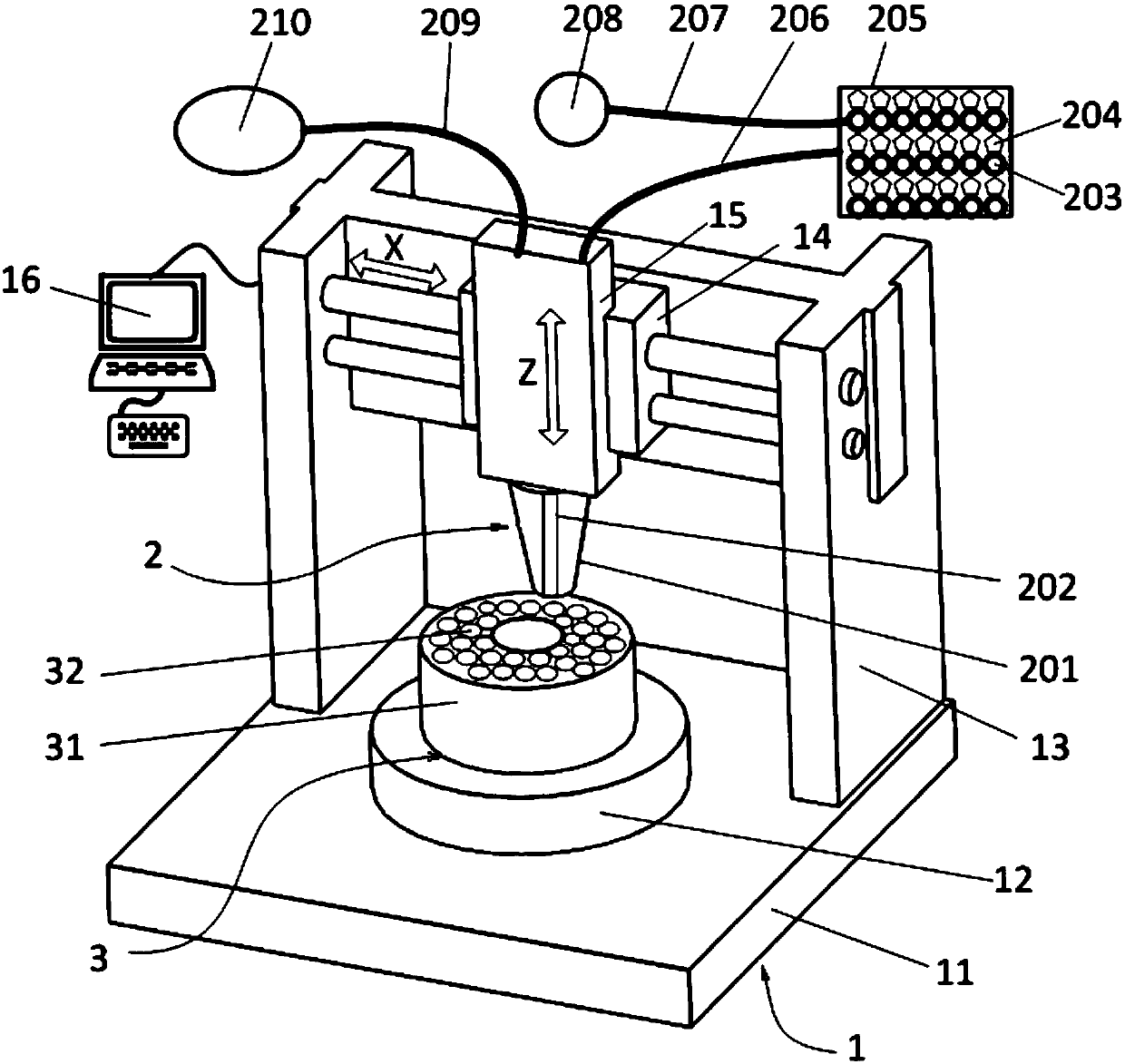

[0050] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0051]3D printing technology of metal parts is currently the most cutting-edge and most potential technology in the entire additive manufacturing technology. It is a bottom-up manufacturing method to realize near-net shape of arbitrary complex parts. With the continuous maturity of laser 3D printing technology, it is possible to prepare metal bonded grinding wheels by 3D printing. A theoretical basis is provided for realizing the present invention.

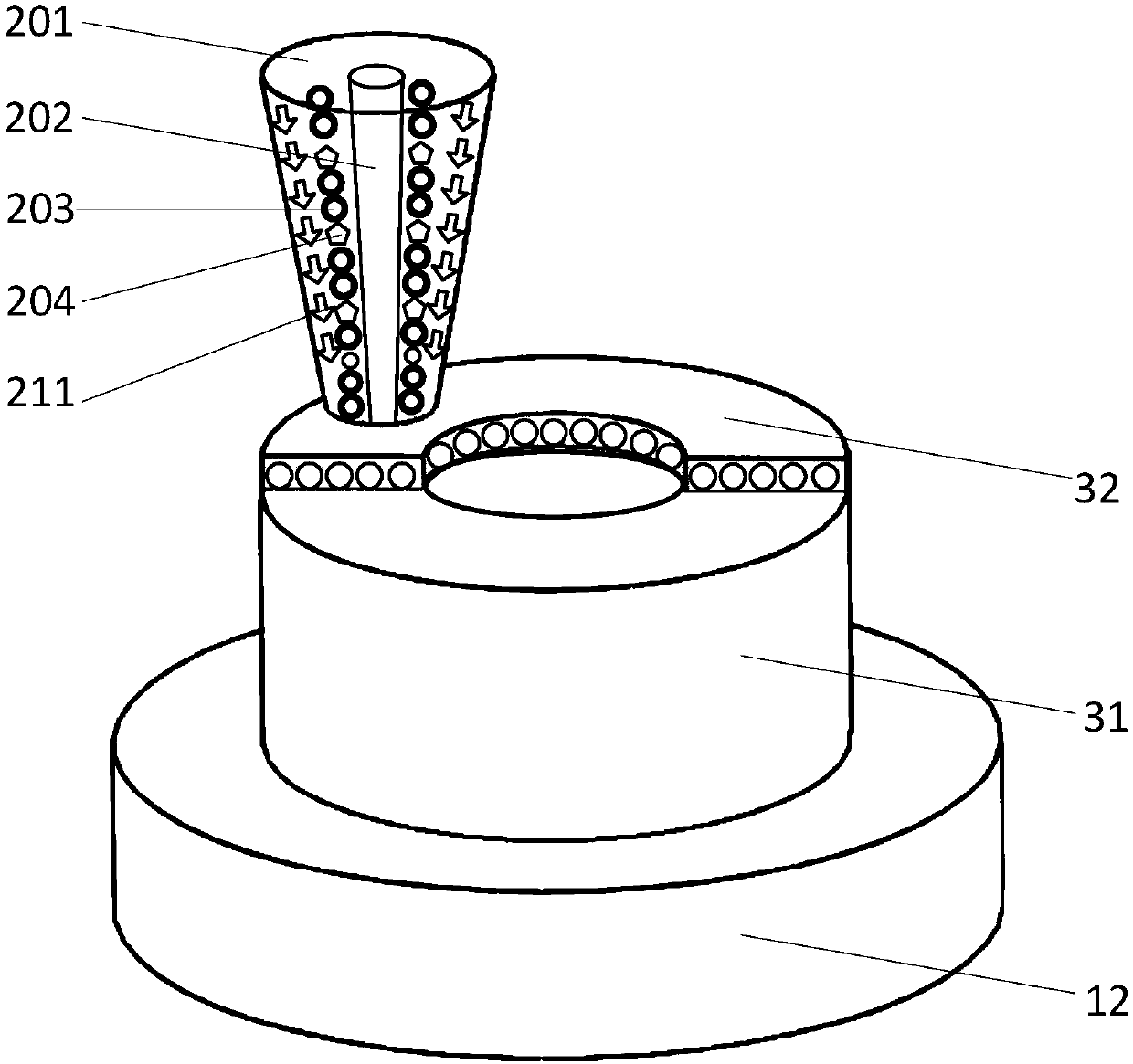

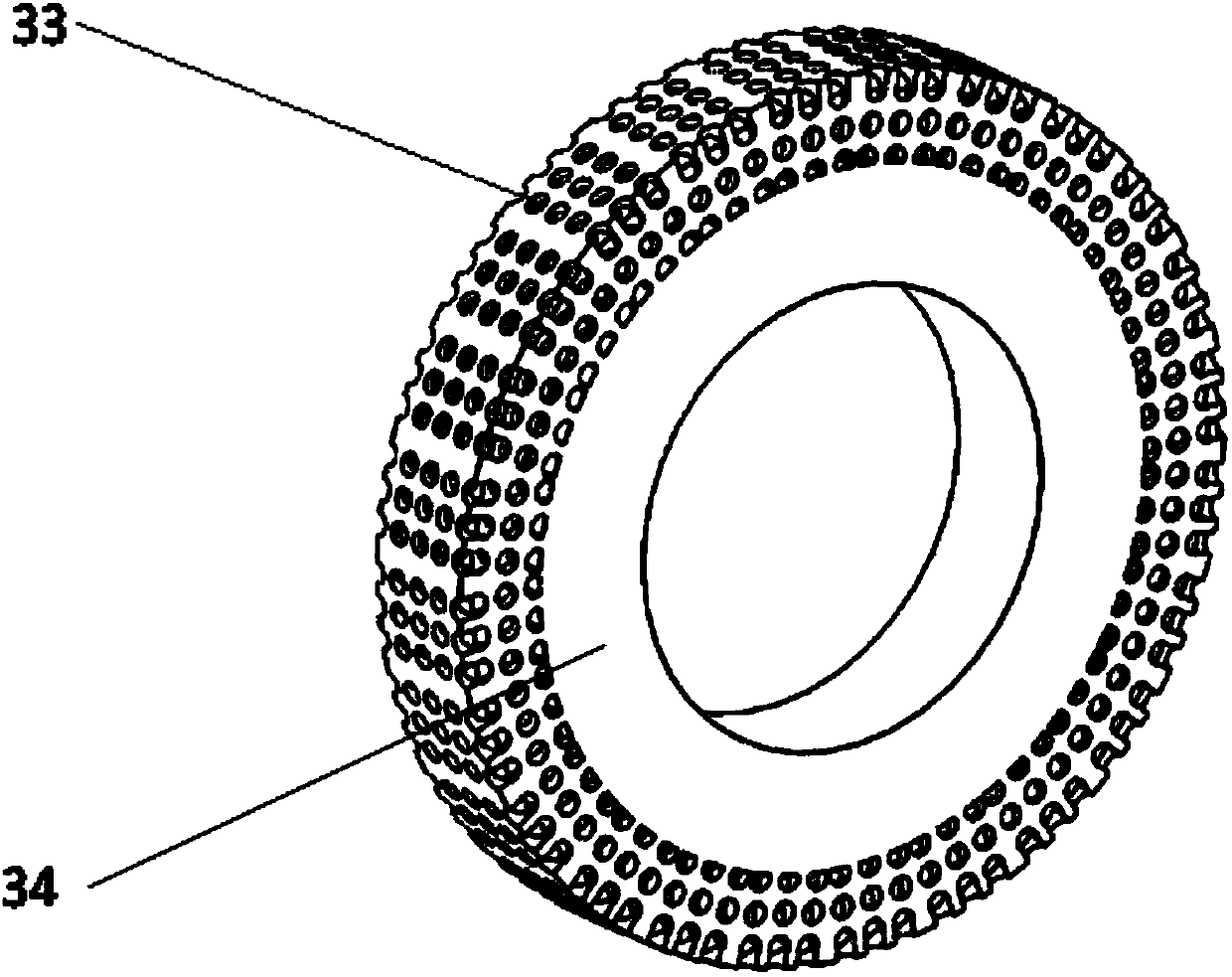

[0052] image 3 It is a schematic structural diagram of the 3D printing grinding whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com