Non-clogging roller screen

A non-clogging, trommel screen technology, applied in the field of trommel screens, can solve the problem that the screen is easily blocked, achieve the effect of preventing clogging and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described now in conjunction with accompanying drawing.

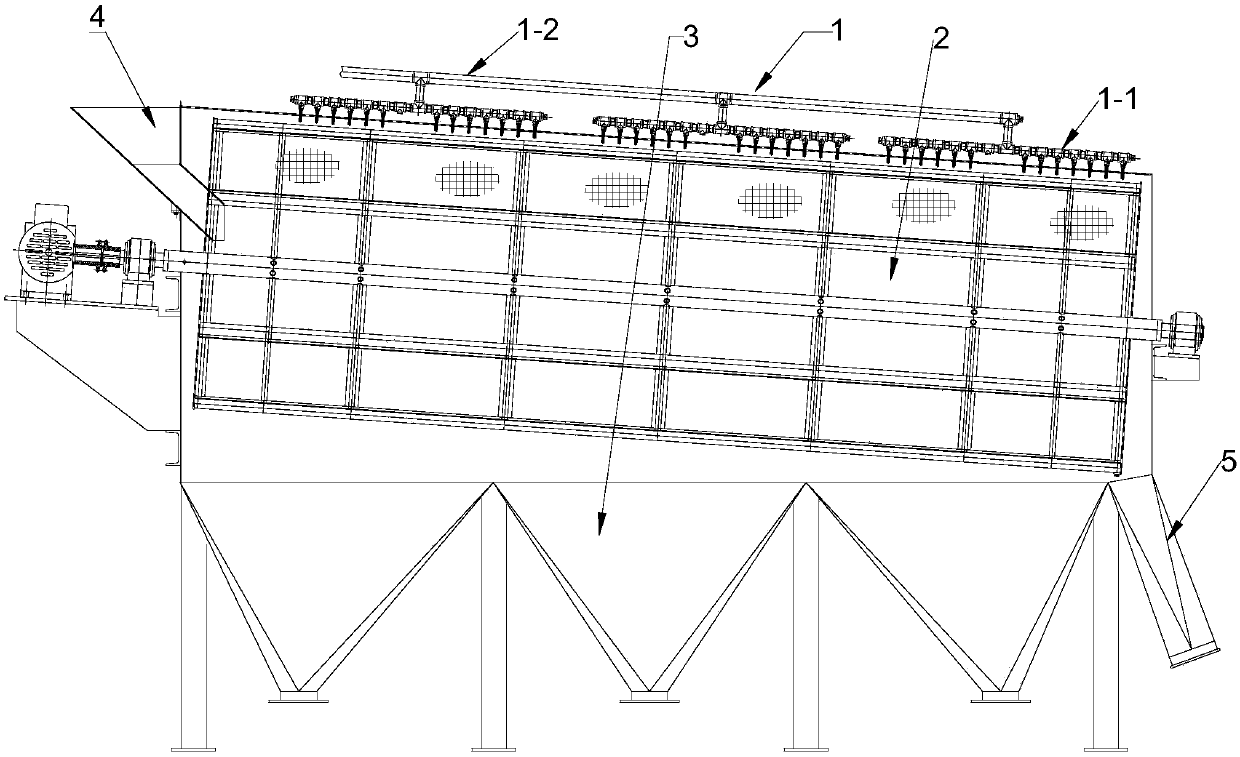

[0032] see Figure 1 ~ Figure 4 , the present invention comprises cylinder body 2, feed port 4, undersize material discharge port 3, coarse material discharge port 5, is characterized in that:

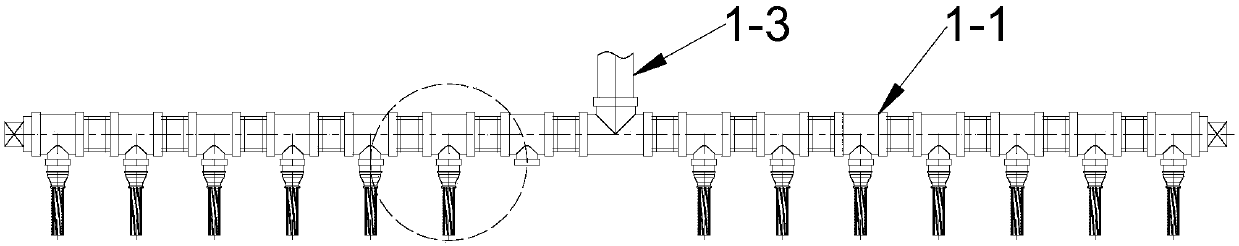

[0033] It also includes a high-pressure air jet device 1 for delivering high-pressure air;

[0034] The high-pressure air jet device 1 is suspended above the cylinder body 2 .

[0035] Further, the high-pressure air jet device 1 is provided with a main gas pipeline 1-2 provided with an air inlet; at least one branch pipe 1-3 communicated with the main gas pipeline 1-2; and each branch pipe 1-2 The outlet end of -3 is connected to the tee pipe device; the tee pipe device is composed of a right dry special-shaped joint 1-12 uniformly distributed in the axial direction on the bottom surface of a main pipe 1-1; and the special-shaped joint 1-12 The outlet port is connected to the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com