Limestone crushing device

A technology of crushing device and limestone, which is applied in the direction of solid separation, removal of smoke and dust, and sieve, etc., can solve the problems such as the difficulty of normal operation of the crushing device and the serious accumulation of limestone dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

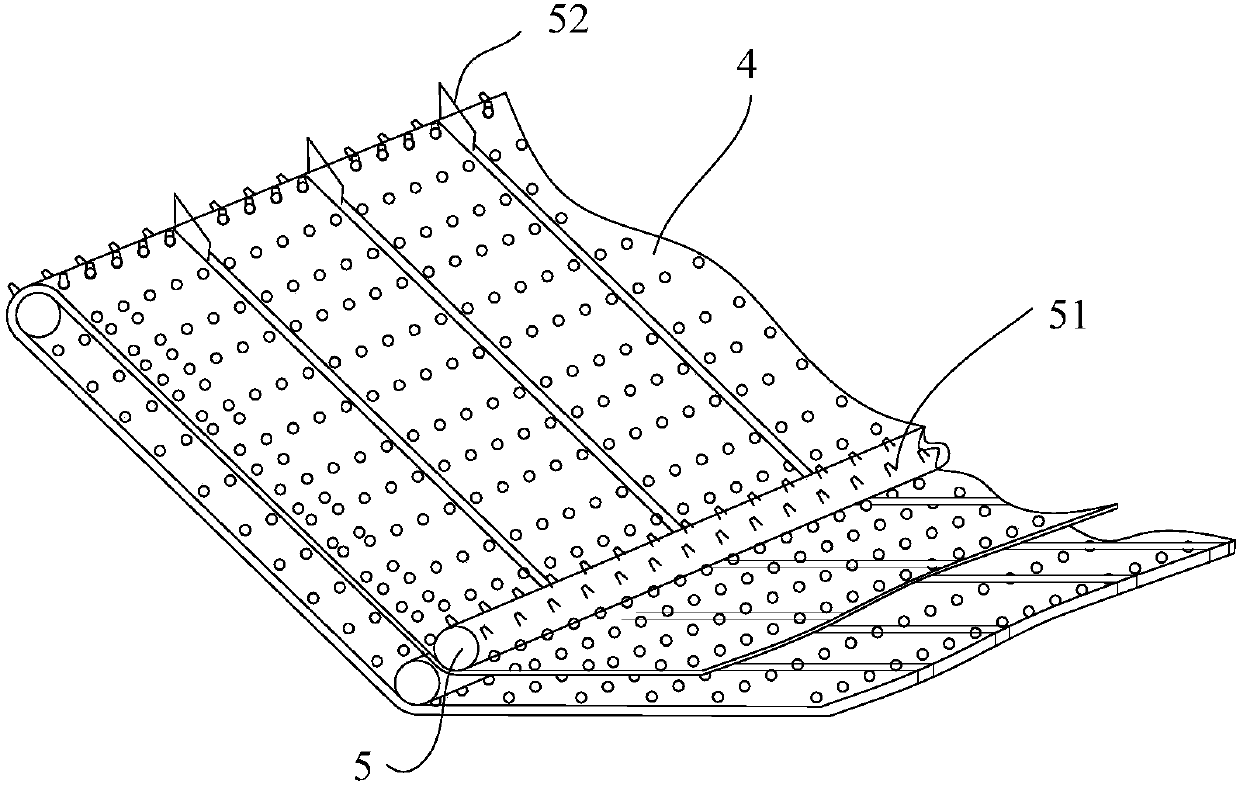

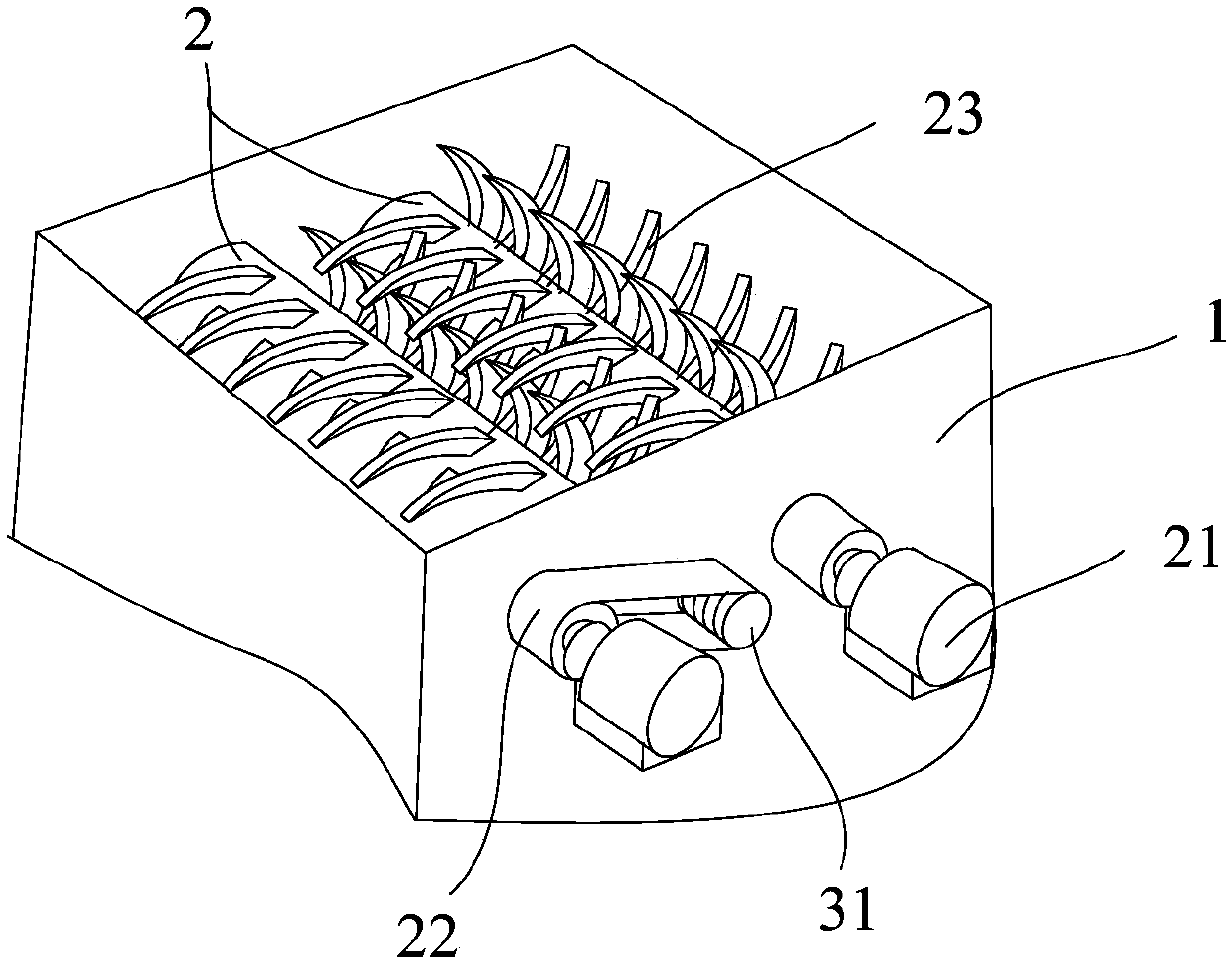

[0016] Such as figure 1 , figure 2 and image 3 The limestone crushing device shown includes a casing 1, a crushing rod and a negative pressure fan 7. The top of the casing 1 is provided with a feeding port 11, and the bottom is provided with a dust removal port 12; the crushing rod is arranged inside the casing 1 and located at the feeding port 11. Directly below, the negative pressure fan 7 is installed at the dust removal port 12. There are screening mechanisms on both sides and below the crushing rod. The screening mechanism includes an elastic screening net 4 made of steel foil. The connected rotating roller 5 and the screening net 4 are connected to the outer surface of the rotating roller 5 through transmission. The screening net 4 and the rotating roller 5 form a U-shaped transmission channel. A plurality of screening nets 4 are connected side by side on the rotating roller 5 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com