Motor end cover, stator assembly and motor

A motor end cover and stator technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of the motor end cover and the motor stator being easily loosened and not firmly fixed, so as to improve product quality and eliminate axial The effect of loosening and tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

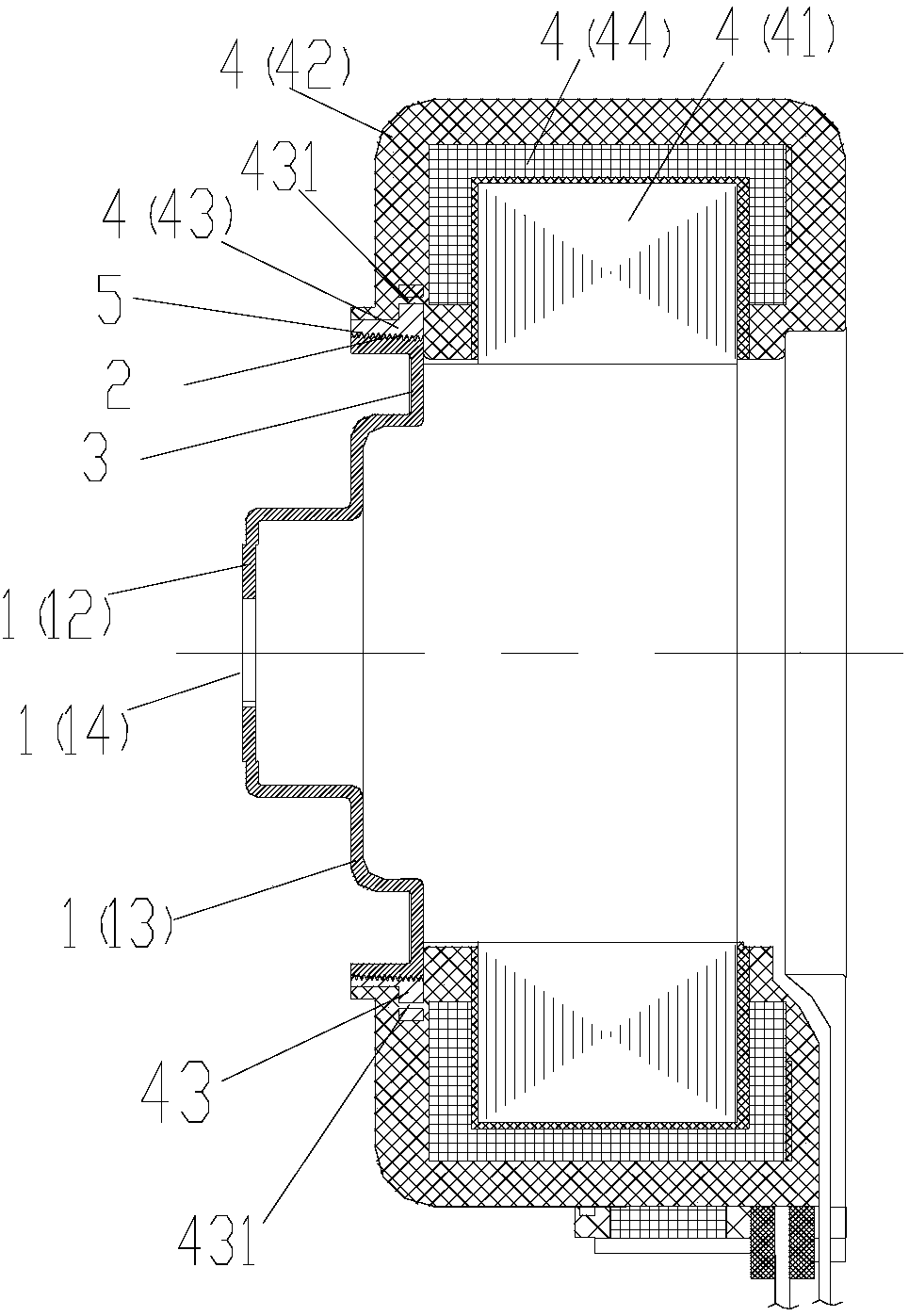

[0039] Such as figure 1 As shown, the present invention provides a motor end cover 1, which includes:

[0040] Flange 11, and an external thread 2 is provided on the outer peripheral wall of the flange 11, and when the motor end cover is engaged with the stator assembly of the motor, a threaded connection is formed with the stator assembly through the external thread 2 .

[0041] By providing external threads on the outer peripheral wall of the flanging of the motor end cover, when the motor end cover is engaged with the stator assembly of the motor, a threaded connection is formed with the stator assembly through the external threads, which can replace the original The motor end cover and the motor are combined by pressing, which effectively solves the defects of looseness and loose fixation between the motor end cover and the stator assembly, especially the end cover that exists after the motor runs hot. The hidden danger of loosening improves product quality and reduces a...

Embodiment 2

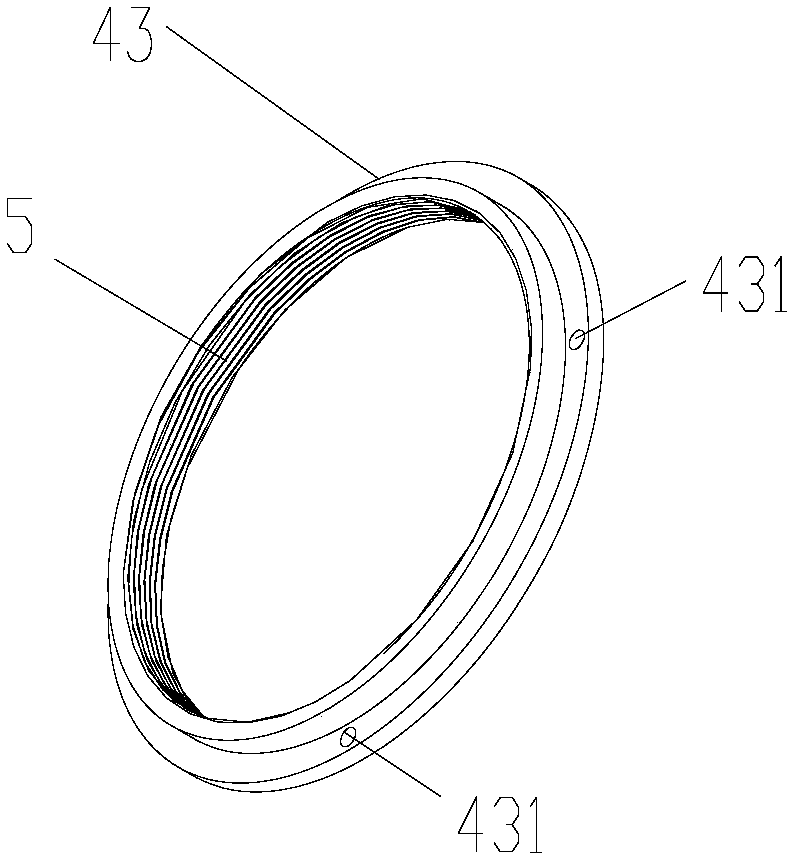

[0056] Such as Figure 2-3 As shown, the present invention also provides a stator assembly 4 having a second axis, comprising:

[0057] Stator 41;

[0058] The plastic sealing part 42 is fixedly arranged on the outer periphery of the stator 41;

[0059] The connecting ring 43 is fixedly arranged on the inner peripheral side of the plastic sealing part 42; the inner peripheral wall of the connecting ring is provided with an internal thread 5, and the stator assembly is connected with the motor end through the internal thread when the stator assembly is engaged with the motor end cover. The cap forms a threaded connection.

[0060] By providing a connecting ring on the stator assembly, and internal threads are provided on the inner peripheral wall of the connecting ring, when the stator assembly is engaged with the motor end cover, the internal thread forms a threaded connection with the motor end cover, which can replace the original The motor end cover and the motor are com...

Embodiment 3

[0075] Such as image 3 , the present invention also provides a motor, which includes the aforementioned motor end cover 1 and the aforementioned stator assembly 4, and the connection between the motor end cover 1 and the stator assembly 4 is through the external thread 2 on the flange 11 and the The internal thread 5 on the connecting ring 43 is threaded. By providing an external thread on the outer peripheral wall of the flanging of the motor end cover, when the motor end cover is engaged with the stator assembly of the motor, the external thread forms a threaded connection with the stator assembly, and, by A connecting ring is arranged on the stator assembly, and an internal thread is provided on the inner peripheral wall of the connecting ring. When the stator assembly is engaged with the motor end cover, the internal thread forms a threaded connection with the motor end cover, which can replace the original motor The end cover and the motor are combined by pressing, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com