Carbon fiber/three-dimensional network graphene composite material preparation method and application thereof

A three-dimensional network, composite material technology, applied in the field of nanomaterials, can solve the problems of poor electrochemical performance, small specific surface area of carbon fiber, low capacitance quality, etc., and achieve the effect of high electrical conductivity, high specific surface area, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

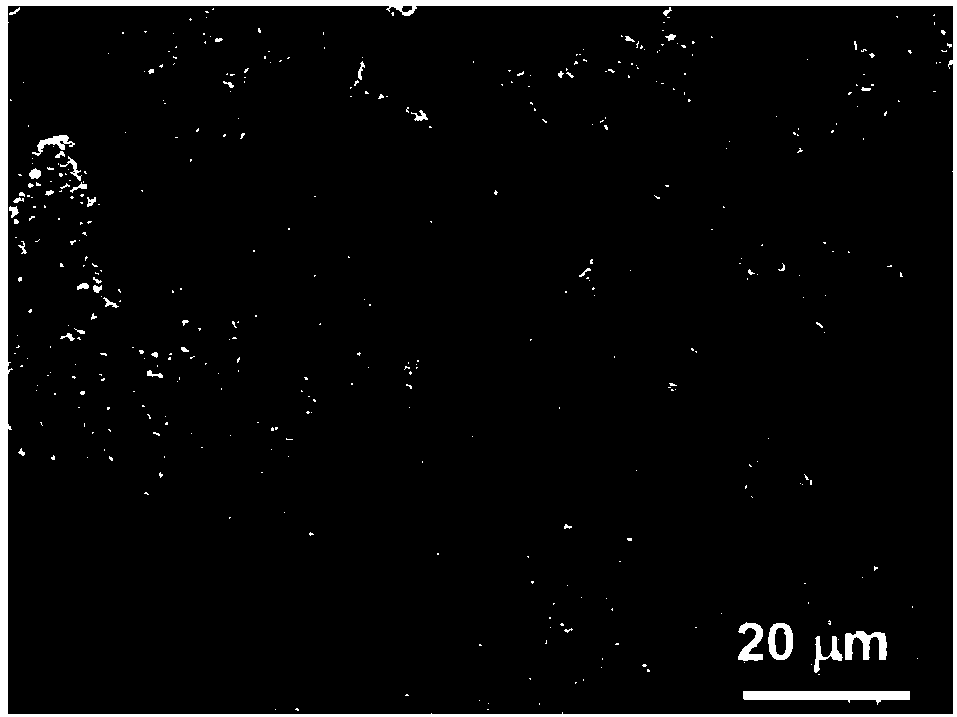

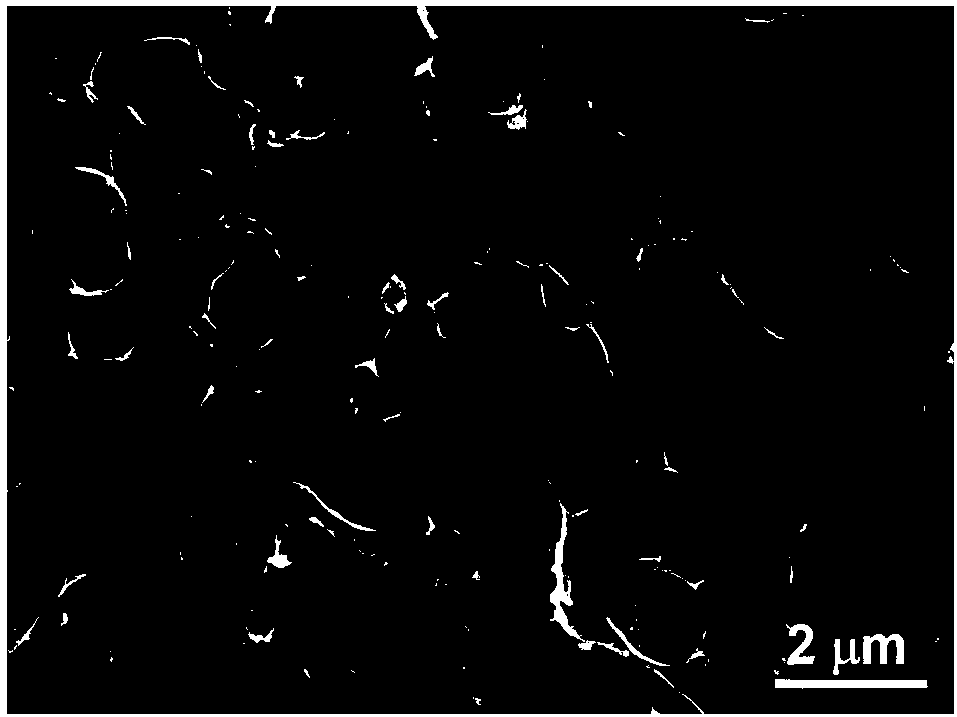

Image

Examples

Embodiment 1

[0030] The preparation method of carbon fiber / three-dimensional network graphene composite material in the present embodiment is as follows:

[0031] 1. Weigh 3 g of PVA solid (molecular weight=20000), add 30 ml of distilled water, and then heat up to 80 ° C and stir to dissolve to obtain a PVA solution; 1.5 g of KOH solid is dissolved in 20 ml of distilled water, then mixed with the PVA solution, and stirred at 70 ° C for 10min , to obtain PVA-KOH solution;

[0032] 2. Weigh 1 g of glucose powder, 1 g of red phosphorus and 0.05 g of nickel acetate, add 30 ml of distilled water, and stir at 70°C for 5 hours until the solution is viscous to obtain a mixture of glucose-red phosphorus-nickel acetate; 10 mL of the PVA-KOH solution obtained in this step was mixed with 10 mL of the glucose-red phosphorus-nickel acetate mixed solution obtained in this step, and stirred evenly to obtain a mixed slurry;

[0033] 3. Coat the mixed slurry obtained in step 2 on carbon fiber paper or PAN ...

Embodiment 2

[0037] The preparation method of carbon fiber / three-dimensional network graphene composite material in the present embodiment is as follows:

[0038] 1. Weigh 1.5g of KOH solid, add 30ml of distilled water, stir and dissolve on a magnetic stirrer to obtain a KOH solution;

[0039] 2. Weigh 3g of glucose, 0.6g of nickel acetate and 0.8g of red phosphorus respectively, add 20mL of distilled water to mix, and stir at 80°C until the solution is viscous to obtain a glucose-red phosphorus-nickel acetate mixed solution; obtain step 1 10 mL of the KOH solution obtained in this step was mixed with 10 mL of the glucose-red phosphorus-nickel acetate mixed solution obtained in this step, and stirred evenly to obtain a mixed slurry;

[0040] 3. Coat the mixed slurry obtained in step 2 on carbon fiber paper (the size is 1cm×1cm, the thickness is 30um), the coating amount of the mixed slurry is 3mL, and it is naturally dried overnight; then sent to a tube furnace, The annealing treatment wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com