Nanocomposite material, preparation method of SDM electrochemical aptamer sensor and detection method

A nanocomposite material and electrochemical technology, which is applied in the preparation of SDM electrochemical aptasensors and in the field of nanocomposite materials, can solve the problems of inability to meet the actual needs of trace SDM, low specificity and sensitivity of detection results, cumbersome and time-consuming operations, etc. , achieve high specificity, improve detection sensitivity, and enhance the effect of electrochemical response signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

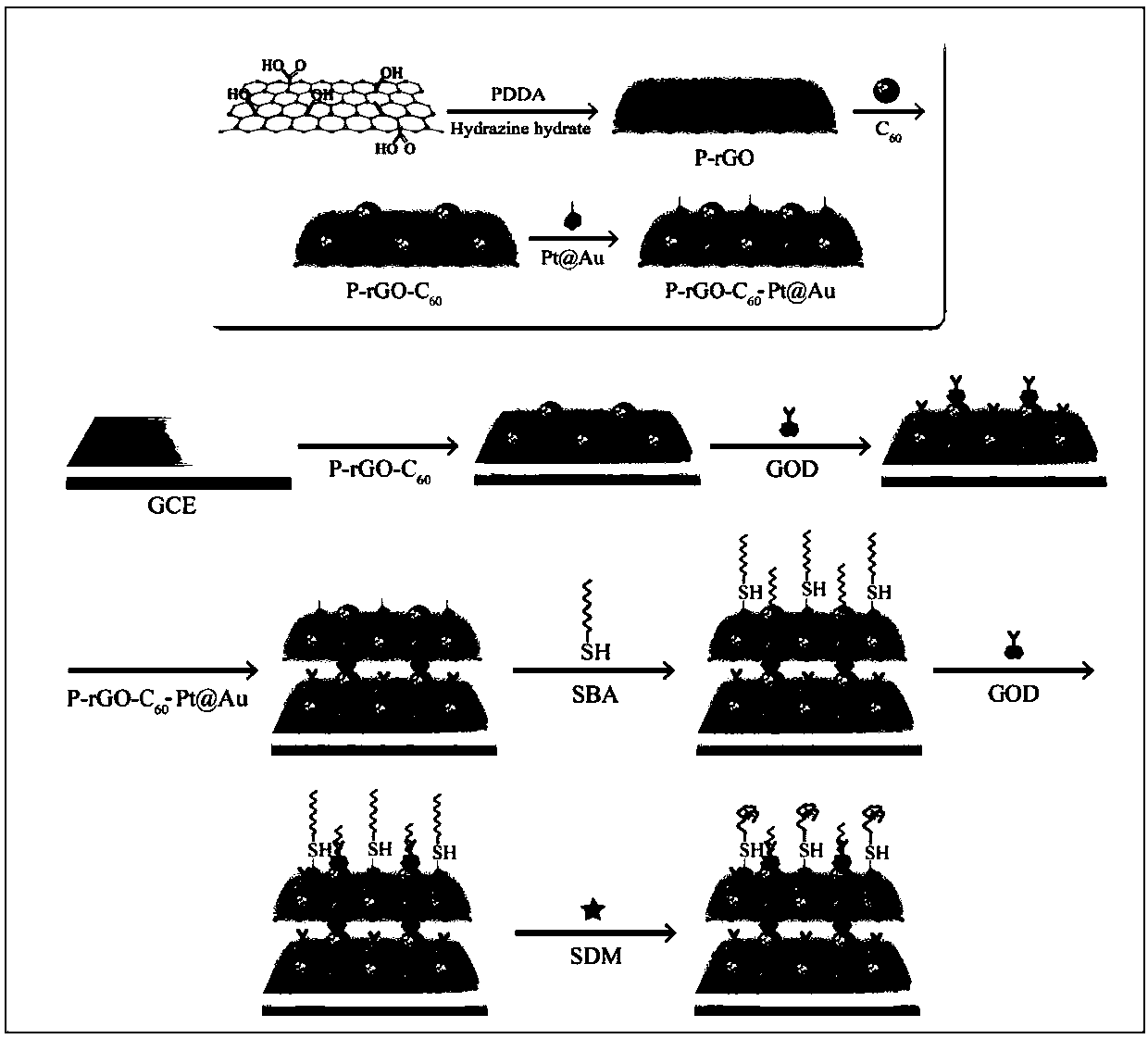

[0046] Example 1 Preparation of P-rGO-C 60 -Pt@Au nanocomposite

[0047] Follow the steps below:

[0048] (1) P-rGO-C 60 Preparation of nanocomposites:

[0049] 1) Add 5mL toluene to 5mg C 60 powder, and then use ultrasonic treatment to obtain a deep purple solution, then add 5mL ultrapure water, stand to separate layers, and then continue ultrasonic treatment for 10-12h until the C of the toluene phase 60 Transfer to the water phase, wait until the toluene is completely evaporated, and finally obtain a brownish yellow solution, and finally filter it with a 0.45 μm filter to obtain pure C 60 aqueous solution.

[0050] 2) ultrasonically disperse 5 mg of graphene oxide (rGO) in 5 mL of ultrapure water, add 5 mL of C prepared in step 1) 60 aqueous solution, and then 40 μL of PDDA (20%) was added dropwise. After stirring for 30 minutes, add 100 μL of hydrazine hydrate (80%) dropwise and react at 90°C for 4 hours; finally centrifuge at 10,000 r / min for 5 minutes to wash exce...

Embodiment 2

[0055] Example 2 Preparation of an electrochemical DNA aptamer sensor for SDM detection

[0056] Follow the steps below: (The construction principle is as follows figure 1 shown)

[0057] 1) Treat the DNA single strand of the thiol-labeled SDM-binding aptamer (SBA) with 10 mM TCEP solution at room temperature for 1 hour, and set aside.

[0058] 2) Use 0.3μm and 0.05μm Al respectively 2 o 3 The glassy carbon electrode (GCE) was polished into a mirror surface, and then the electrodes were ultrasonically treated in the order of ultrapure water, absolute ethanol, and ultrapure water for 5 minutes each, and dried at room temperature for later use.

[0059] 3) Place the electrode obtained in step 2) in 0.5M H 2 SO 4 Electrochemical cleaning was carried out in the medium, and the potential sweep was 0.2-1.6V until a stable cyclic voltammogram was obtained, and then rinsed with ultrapure water again and dried in air.

[0060] 4) 8 μL of the P-rGO-C prepared in Example 1 60 The ...

Embodiment 3

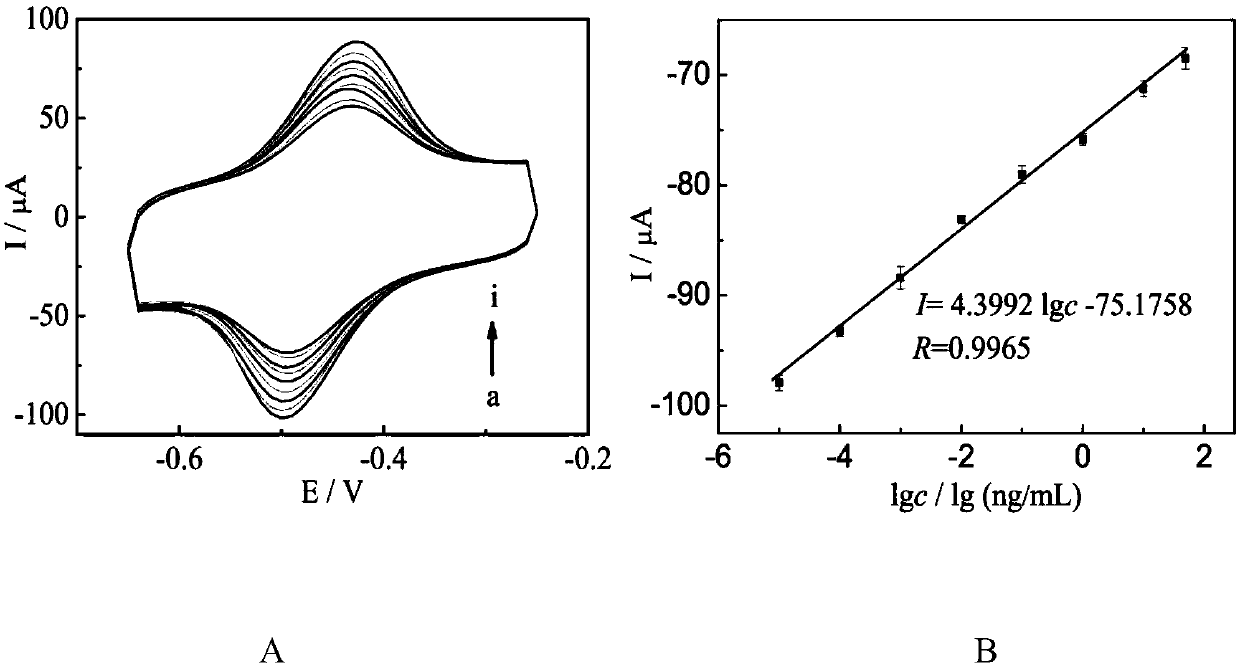

[0064] Example 3 Detection of SDM by electrochemical DNA aptamer sensor

[0065] Using the electrochemical DNA aptamer sensor constructed in Example 2 to detect SDM, follow the steps below:

[0066] 1. Draw the working curve

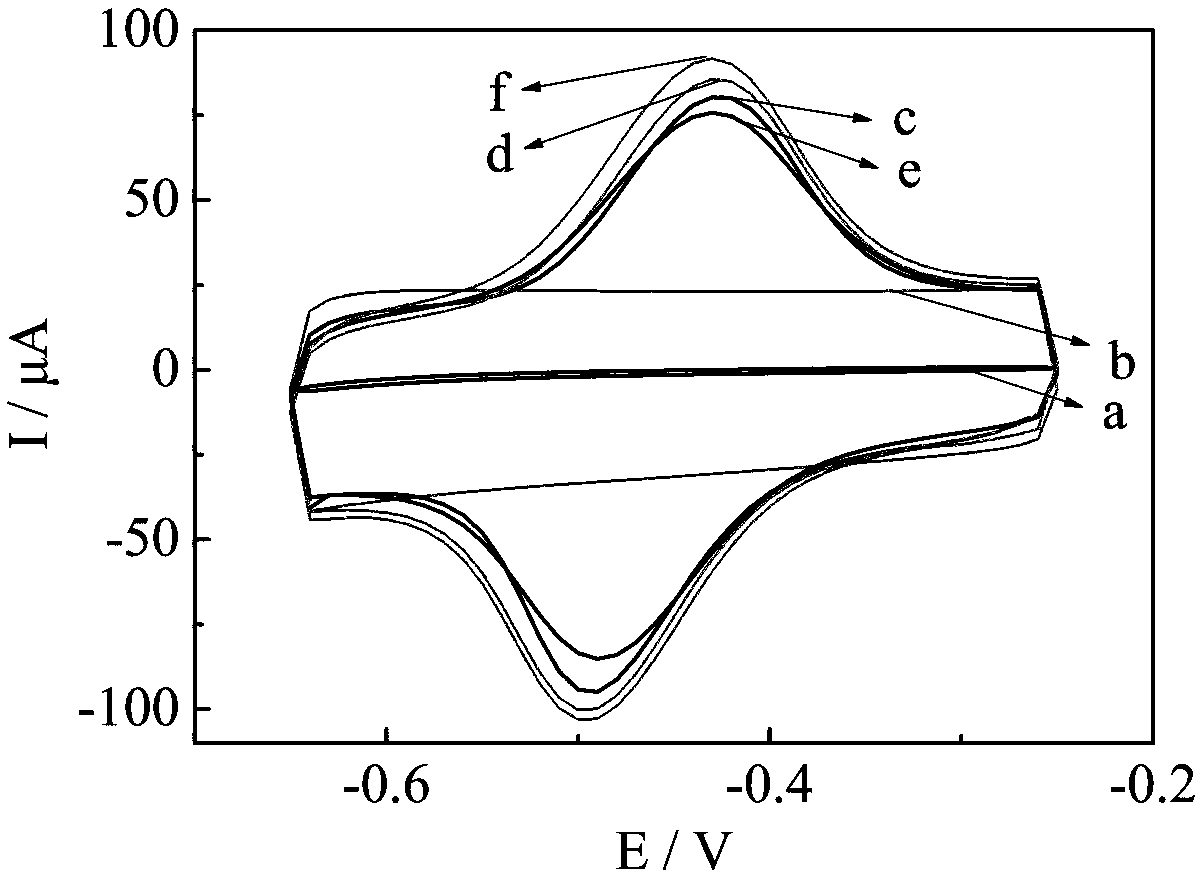

[0067] 1) The modified electrodes from Step 3) to Step 7) of Example 2 were respectively placed in 0.1M Na 2 HPO 4 , 0.1M KH 2 PO 4 , 10M KCl and 2mM MgCl 2 Characterized in 0.1M PBS, measured its electrochemical response signal, the results are as follows figure 2 Shown: (a) bare GCE; (b) dropwise addition of P-rGO-C 60 ; (c) Incubation of GOD; (d) dropwise addition of P-rGO-C 60 -Pt@Au; (e) combined with SBA; (f) blocked by GOD.

[0068] 2) Add 20 μL of the target substance sulfadimethoxine at different concentrations dropwise to the electrode of the aptamer sensor prepared in Example 2, and measure the current changes thereof respectively.

[0069] 3) According to the linear relationship between the obtained current change value and the loga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com