Pressure tank for testing performance of underwater connector

A technology for pressure tanks and connectors, which is applied in pressure vessels, electrical connection tests, and the use of stable tension/pressure tests to test the strength of materials. problem, to achieve the effect of improving efficiency, ensuring test stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are specifically described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the present application, and together with the embodiments of the present invention, are used to explain the principles of the present invention, but are not used to limit the scope of the present invention.

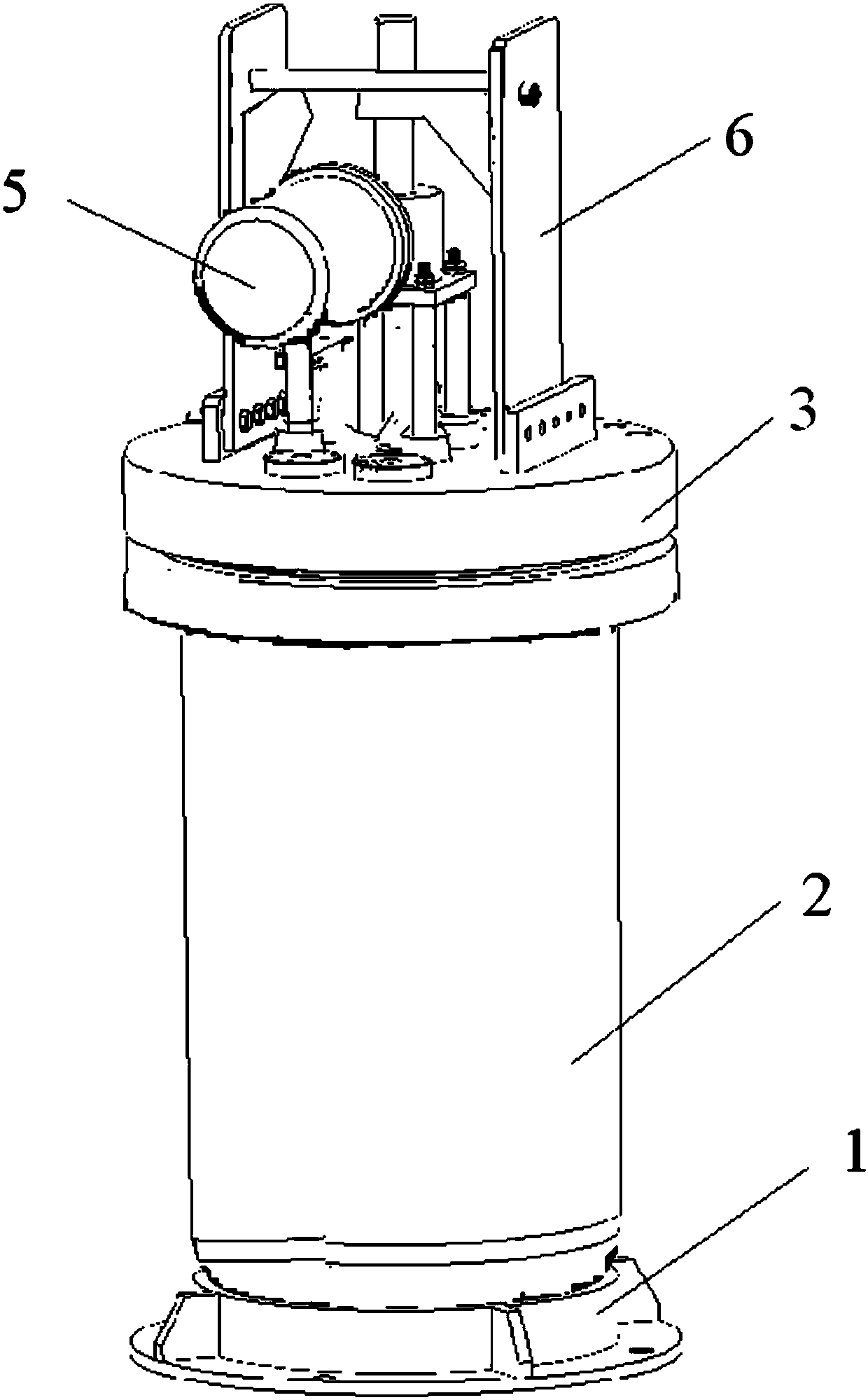

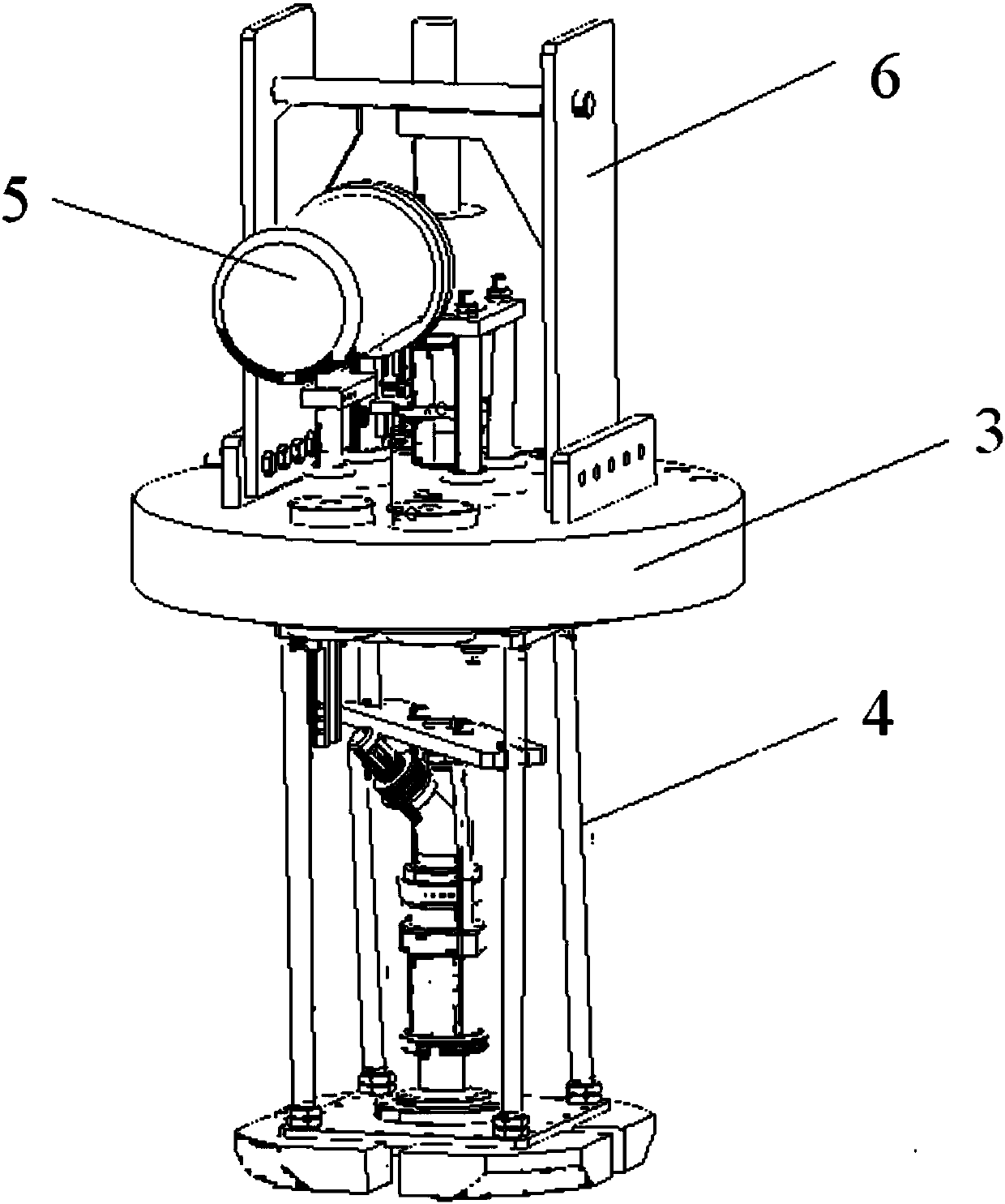

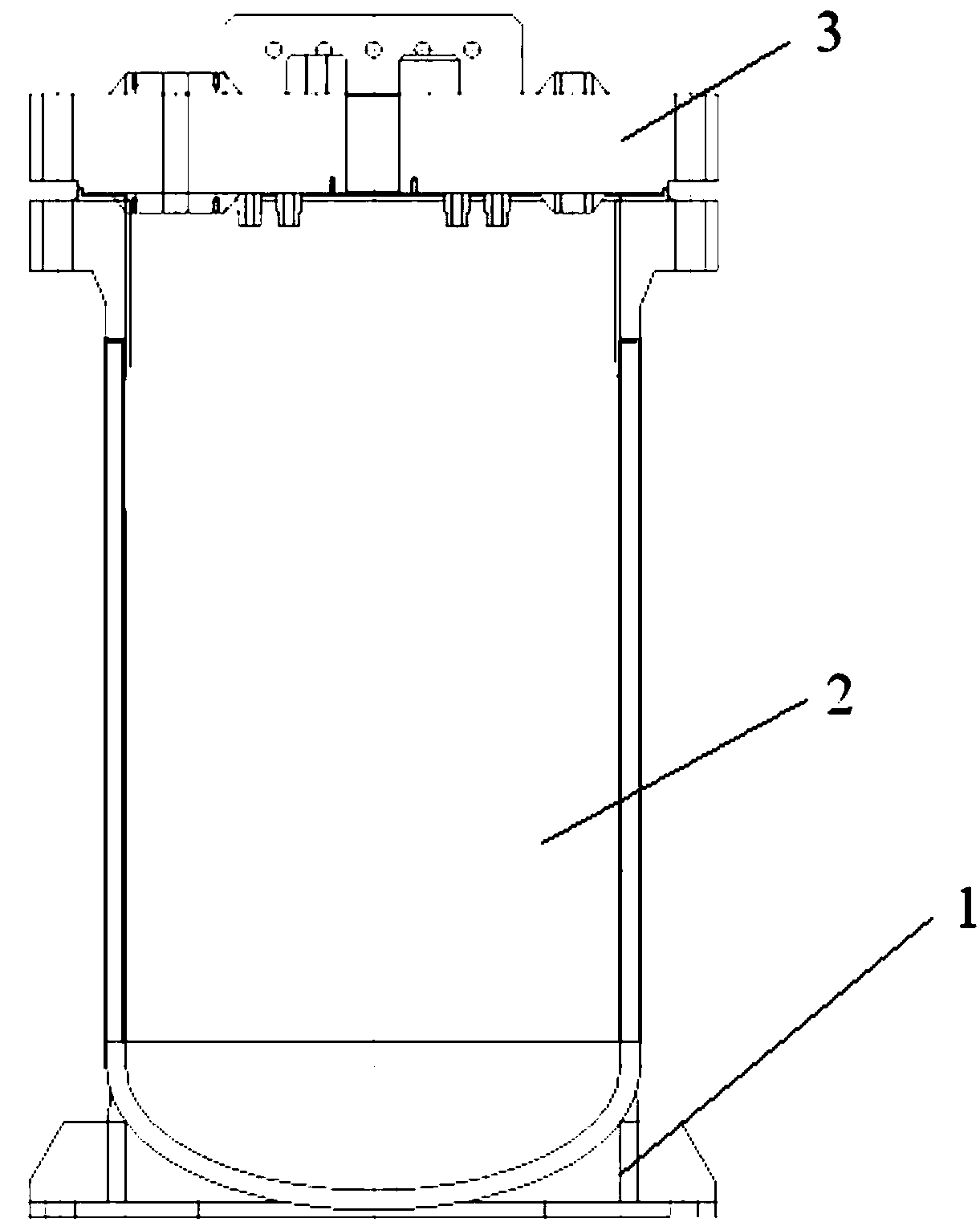

[0036] A specific embodiment of the present invention discloses a pressure tank for testing the performance of underwater connectors, such as figure 1 , 2 As shown, it includes a base 1, an autoclave 2, a sealing cover 3, a motor assembly 5, a test piece installation assembly 4, and a lifting attachment 6;

[0037] Wherein, the lower end of the autoclave 2 is fixedly connected with the base 1, the sealing cover 3 is sealed and connected with the upper end of the autoclave 2, and a hole is opened in the middle of the sealing cover 3, and the connecting rod of the motor assembly 5 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com