Icing monitoring and self-adaptive deicing integrated system and method for wind power blade

A wind power blade, self-adaptive technology, applied in wind power generation, wind engine, machine/engine, etc., to achieve the effect of reducing energy consumption and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with drawings and embodiments.

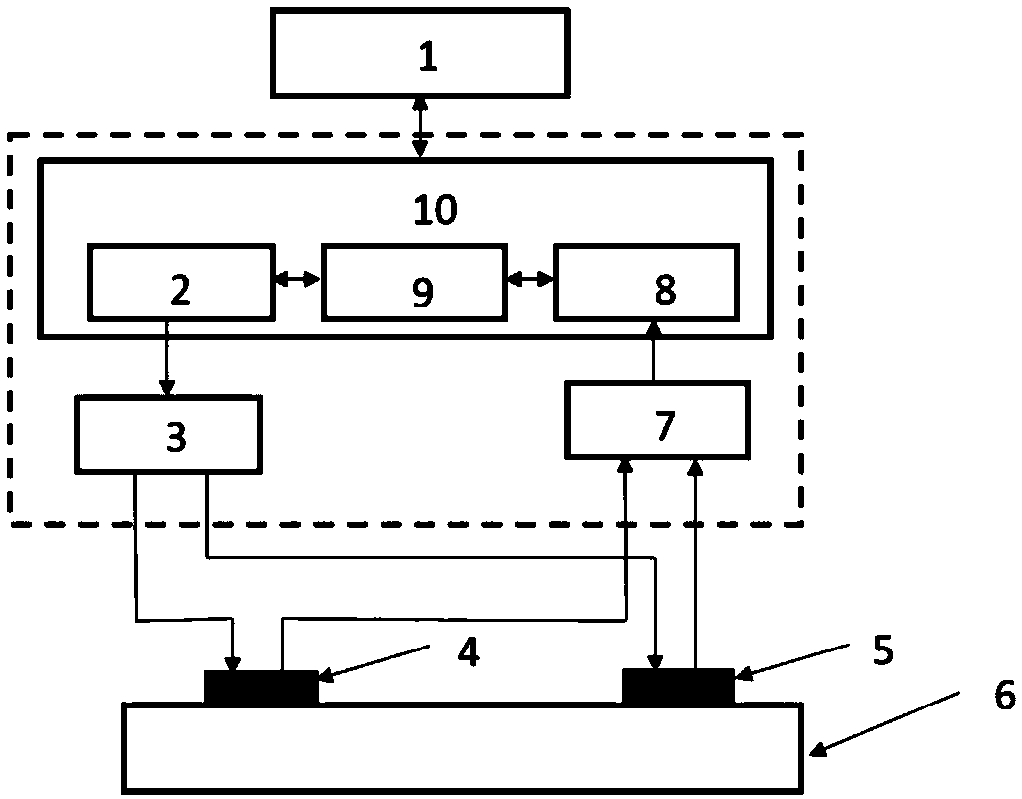

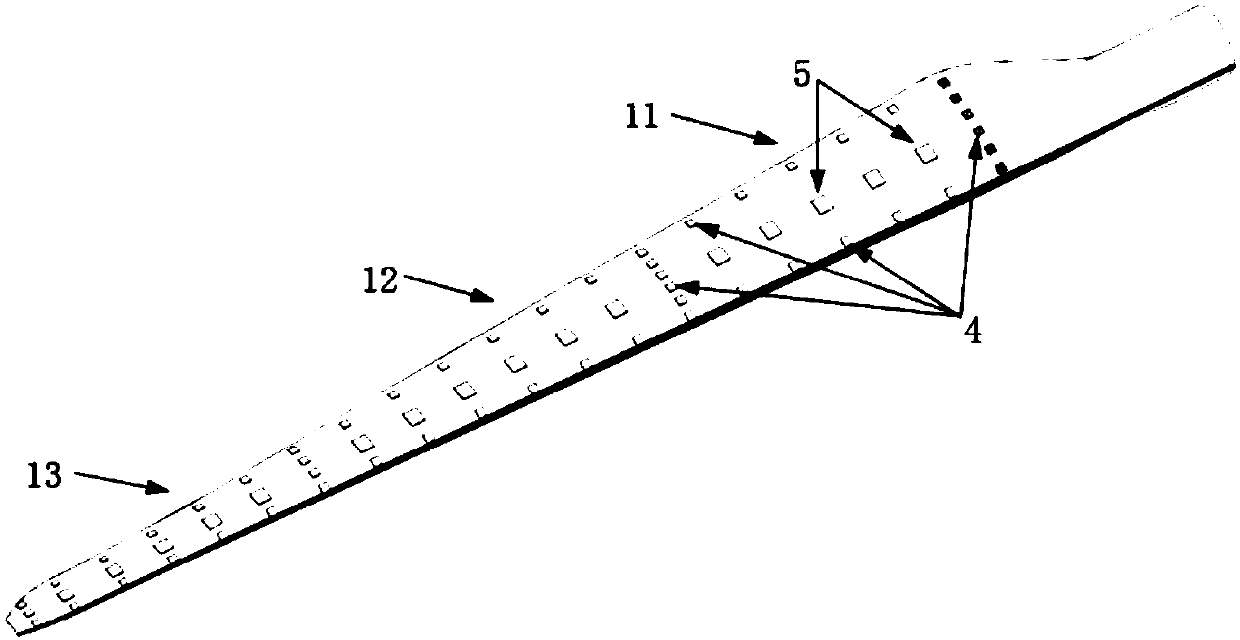

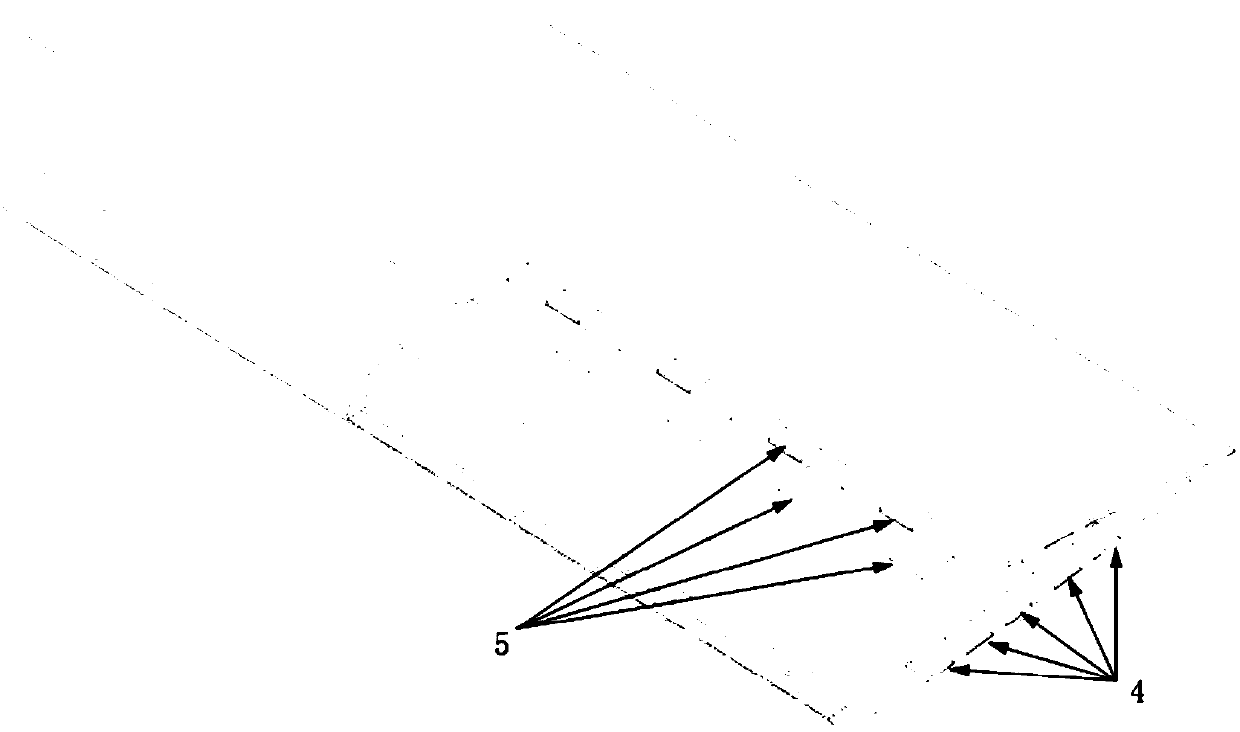

[0048] like figure 1 As shown, the specific implementation of the system of the present invention includes a host computer 1, a power amplification module 3, a monitoring transducer array 4, a deicing transducer array 5, a wind turbine blade 6, a preamplification module 7 and a multi-channel signal control and processing module 10. The multi-channel signal control and processing module 10 includes a multi-channel excitation signal generation unit 2 , a multi-channel echo signal processing unit 8 and a timing control unit 9 .

[0049] like figure 1 As shown, the monitoring transducer array 4 and the deicing transducer array 5 are arranged on the wind power blade 6, the host computer 1 is connected with the multi-channel signal control and processing module 10, and the multi-channel signal control and processing module 10 The channel excitation signal generating unit 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com