Rubbing polishing treatment method for Chinese lacquer on surface of leather

A processing method and technology of leather materials, applied in the direction of leather surface mechanical treatment, fur mechanical treatment, small raw hide/big raw hide/leather/fur treatment, etc., can solve problems such as shedding, easy cracking, breakage, etc., to protect the properties of leather materials , Improve artistry and aesthetic value, practical and aesthetic value good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with implementation modes and examples.

[0024] This embodiment provides a method for polishing and wiping paint on the surface of leather, comprising the following steps:

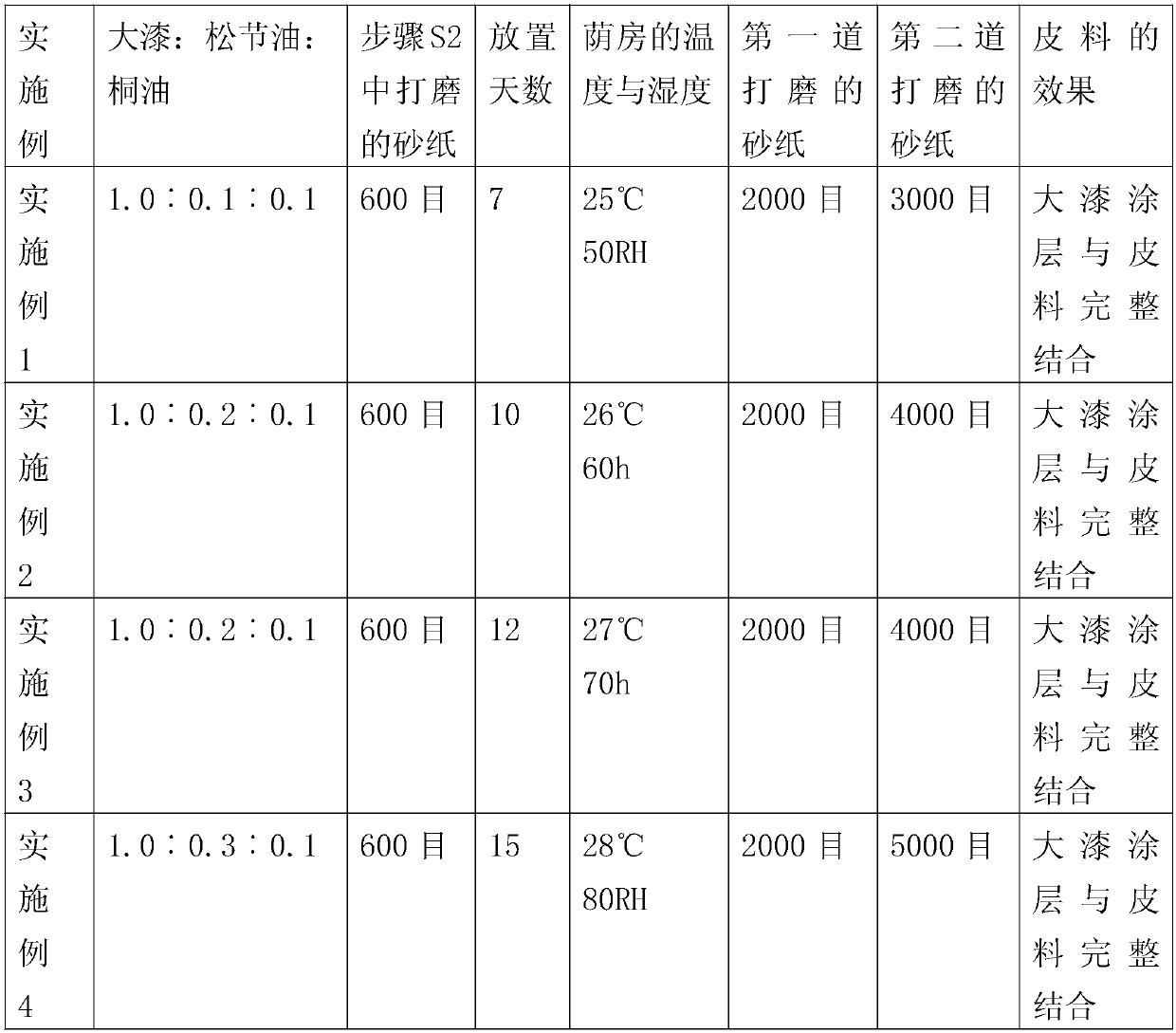

[0025] Step S1: mixing lacquer, turpentine and tung oil evenly according to a certain ratio, and preparing a lacquer paint;

[0026] Step S2: sanding the wax or oil on the leather surface with sandpaper to pretreat the leather;

[0027] Step S3: Apply the lacquer coating on the surface of the pretreated leather material. After the leather material fully absorbs the lacquer coating, place the leather material in a cool and humid place for natural shade drying;

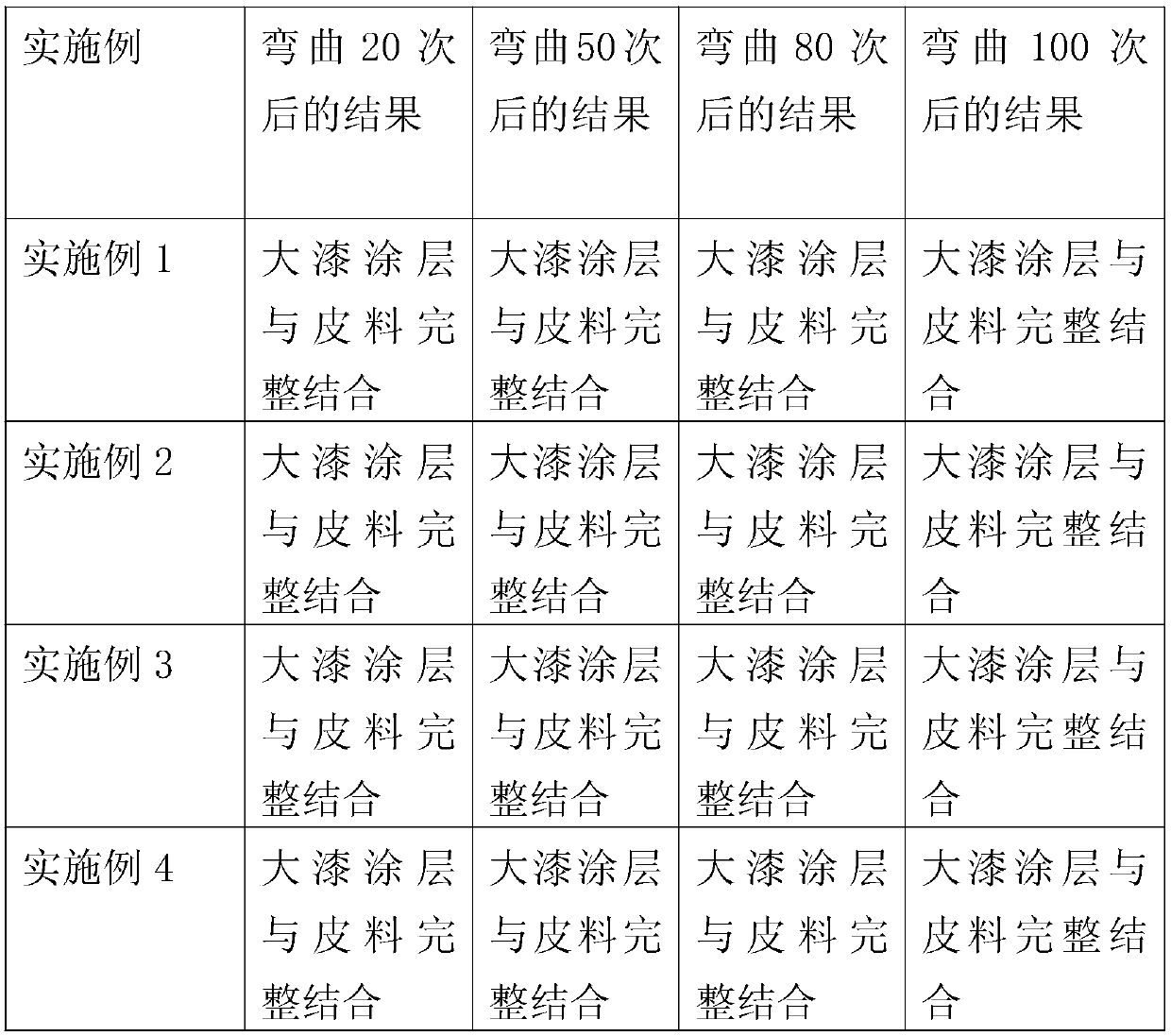

[0028] Step S4: Leave the leather for a certain number of days, so that the lacquer coating is completely cured on the surface of the leather to form a lacquer coating, then use sandpaper to first polish the cured lacquer coating to remove the paint film covering the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com