A kind of aesthetic resin composition with improved appearance and preparation method thereof

A technology of aesthetic resin and composition, which is applied in the field of aesthetic resin composition for improving appearance and its preparation, can solve the problems of matrix resin processability limitation, narrow application range, etc., achieve simple implementation, improve effect, improve flow marks and welding line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

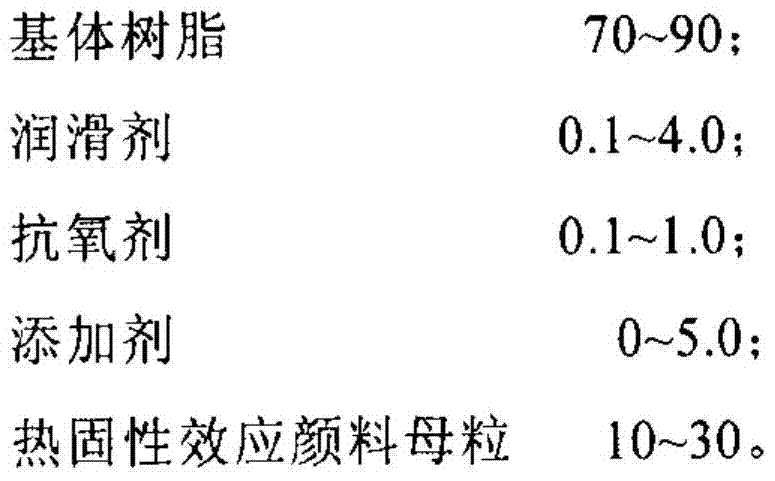

Method used

Image

Examples

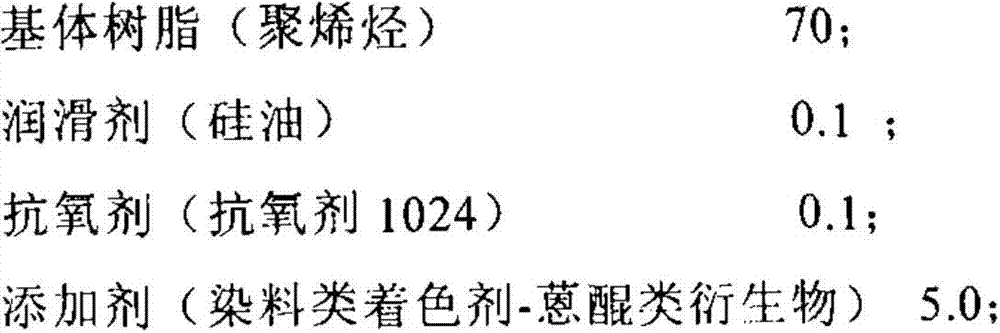

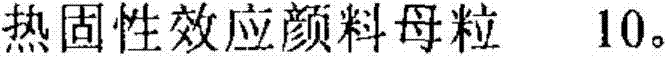

Embodiment 1

[0042] This embodiment relates to a resin composition for improving the appearance of aesthetic plastics and a preparation method thereof. The preparation method includes the following steps:

[0043] (1) Mixing and dispersing the metal pigment into the prepolymer of epoxy resin; coating the mixture to form a film, curing and granulating; the content of the effect pigment after curing is 4.0%. The initial degradation temperature of TGA test is 295°C.

[0044] (2) Prepare materials according to the following components and parts by weight:

[0045] Base resin 90,

[0046] Lubricant 2.0,

[0047] Antioxidant 0.3,

[0048] UV absorber 0.5,

[0049] The thermosetting effect pigment masterbatch 10 prepared in step (1).

[0050] (3) Put the above-mentioned (2) raw materials in a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conditions of transportation, shearing and mixi...

Embodiment 2

[0053] This embodiment relates to a resin composition for improving the appearance of aesthetic plastics and a preparation method thereof. The preparation method includes the following steps:

[0054] (1) Mix and disperse the pearlescent pigment into the prepolymer of the epoxy resin; coat the mixture to form a film and then solidify and granulate; the content of the cured effect pigment is 8.0%. The initial degradation temperature of TGA test is 292°C.

[0055] (2) Prepare materials according to the following components and parts by weight:

[0056] Base resin 90,

[0057] Lubricant 2.0,

[0058] Antioxidant 0.3,

[0059] The thermosetting effect pigment masterbatch 10 prepared in step (1).

[0060] (3) Put the above-mentioned (2) raw materials in a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of materials, the materials are melted...

Embodiment 3

[0063] This embodiment relates to a resin composition for improving the appearance of aesthetic plastics and a preparation method thereof. The preparation method includes the following steps:

[0064] (1) Mix and disperse the pearlescent pigment into the prepolymer of the epoxy resin; coat the mixture to form a film and then solidify and granulate; the content of the cured effect pigment is 8.0%. The initial degradation temperature of TGA test is 290°C.

[0065] (2) Prepare materials according to the following components and parts by weight:

[0066] Base resin 90,

[0067] Lubricant 2.0,

[0068] Antioxidant 0.3,

[0069] The thermosetting effect pigment masterbatch 20 prepared in step (1).

[0070] (3) Put the above-mentioned (2) raw materials in a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of materials, the materials are melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com