Agricultural composite microbial agent and preparation method of same

A technology of compound bacterial agent and bacterial liquid, applied in biochemical equipment and methods, methods based on microorganisms, bacteria, etc., can solve the problems of low efficiency of bacteria, high requirements for storage conditions, short shelf life of bacteria, etc., to improve The effect of raising product quality, enhancing disease resistance, and high content of humic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the bacterial liquid is as follows: the bacteria are cultured in the bacterial seed culture medium at 37°C for 24 hours; then cultivated in the bacterial shaker culture medium at 37°C and the shaker speed is 180r / min for 18 hours; finally in the bacteria Fermentation culture medium, 37 ℃, shaker speed is 180r / min under the fermentation culture for 36 hours, after the fermentation culture is completed, the mother liquor is obtained, which is the bacterial bacterial liquid. The spore production rate in the bacterial bacterial liquid is more than 90%, and the number of effective viable bacteria ≥5.0×10 9 cfu / mL;

[0056] Wherein, the composition of bacterial seed culture medium and bacterial shaker culture medium is identical;

[0057] Bacteria seed culture medium is: peptone 1%, yeast extract 0.5%, sodium chloride 1%, the rest is water, pH is 7.0;

[0058] The bacterial fermentation medium is: starch 5%, peptone 1.5%, sodium chloride 0.6%, the ...

Embodiment 1

[0072] Each bacterium solution obtained above is inoculated into the comprehensive culture medium for fermentation according to the volume ratio of 35% of bacteria, 35% of yeast, 10% of lactic acid bacteria, 10% of actinomycetes and 10% of filamentous fungi, and the volume ratio of inoculation is 10%, cultivated for 7 days at 30° C. with a shaker speed of 150 r / min to obtain a liquid agricultural composite bacterial agent. The effective viable bacteria detection results of the liquid agricultural composite bacterial agent are shown in Table 1.

[0073] The components and parts by weight in the comprehensive medium are: 0.08 parts of molasses, 2 parts of honey, 1 part of ascorbic acid, 2.5 parts of ammonium sulfate, 2 parts of dipotassium hydrogen phosphate, 0.2 parts of magnesium sulfate, 1 part of yeast extract, 1000 parts of water share.

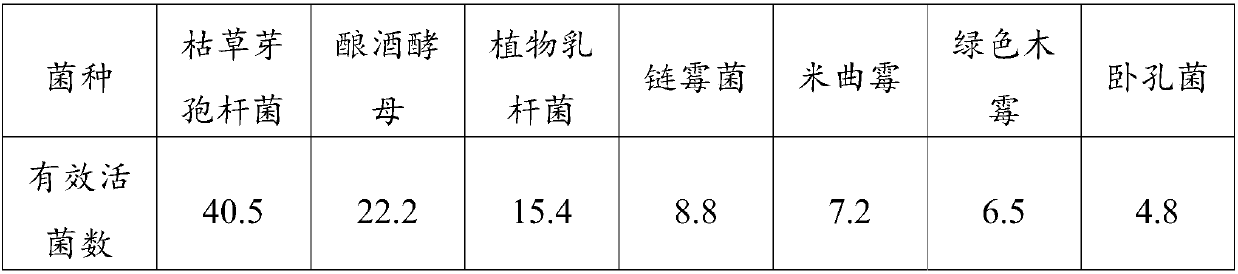

[0074] Table 1: Detection results of liquid agricultural compound bacterial agents (unit: ×10 8 cfu / mL)

[0075]

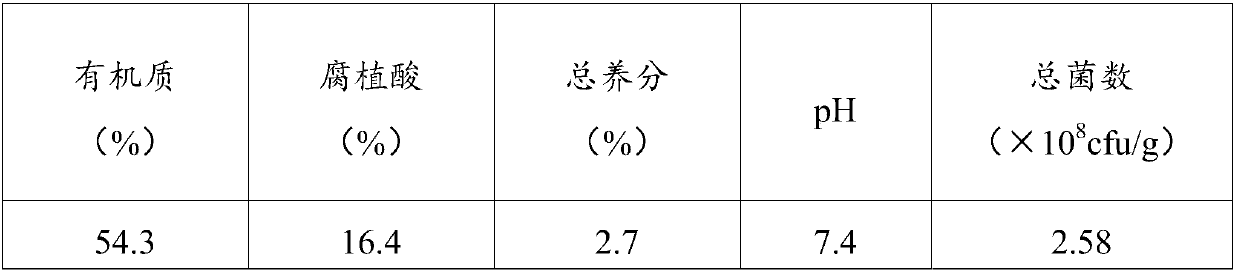

[0076] After test...

Embodiment 2

[0085] Each bacterium solution obtained above is inoculated into the comprehensive culture medium for fermentation according to the volume ratio of 25% of bacteria, 25% of yeast, 20% of lactic acid bacteria, 15% of actinomycetes and 15% of filamentous fungi, and the volume ratio of inoculation is 10%, cultivated for 10 days at 30° C. with a shaker speed of 150 r / min to obtain a liquid agricultural compound bacterial agent. The effective viable bacteria detection results of the liquid agricultural compound bacterial agent are shown in Table 4.

[0086] The components and parts by weight in the comprehensive medium are: 0.08 parts of molasses, 2 parts of honey, 1 part of ascorbic acid, 2.5 parts of ammonium sulfate, 2 parts of dipotassium hydrogen phosphate, 0.2 parts of magnesium sulfate, 1 part of yeast extract, 1000 parts of water share.

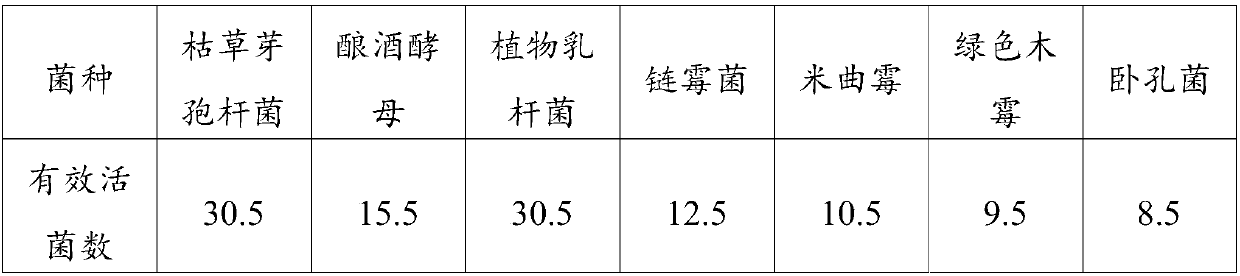

[0087]Table 4: Detection results of liquid agricultural compound bacterial agents (unit: ×10 8 cfu / mL)

[0088]

[0089] After testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Spore count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com