Asphalt reclaiming agent as well as preparation method and application thereof

A technology of asphalt regenerant and asphalt mixture, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of poor thermal stability, poor regeneration effect, and complicated varieties, and achieve good heat resistance and light stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

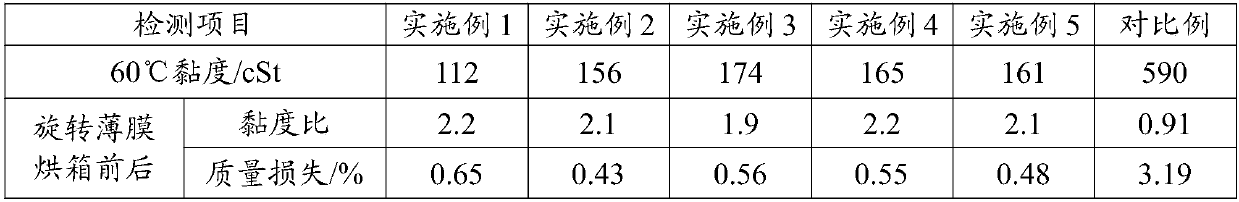

Examples

preparation example Construction

[0027] The present invention also provides the preparation method of the asphalt regenerant described in the above technical scheme, comprising the following steps:

[0028] The asphalt rejuvenator is obtained by mixing light base oil, plasticizer, stabilizing balance group and penetrating agent.

[0029] In the present invention, the mixing temperature is preferably 140-150°C, more preferably 145-148°C. In the present invention, there is no special limitation on the specific mixing method, and a mixing method well known to those skilled in the art is adopted, such as mechanical stirring. In the present invention, the rotational speed of the mechanical stirring is preferably 1000-2000 r / min, and the time of the mechanical stirring is preferably 30 min. In the present invention, the mechanical stirring is preferably carried out under heat preservation conditions, and the heat preservation temperature is preferably a mixing temperature, which will not be repeated here. In the ...

Embodiment 1

[0036] The dosage of each raw material in this embodiment is as follows (parts by weight, the total mass is 100 g): 30 g of light base oil, 30 g of plasticizer, 30 g of stabilizing and balancing agent, and 10 g of penetrating agent. Wherein the light base oil is the minus four-line extraction oil (the mass loss of the light base oil is 0.8% after the rotating film aging test; the viscosity ratio before and after aging is 1.8), the additive component is epoxy soybean oil, and the stabilizing balancer is It is rich in colloidal heavy oil (the mass content of colloid is 90%), and the penetrating agent is petroleum ether.

[0037] The preparation method comprises the following steps: firstly weigh the light base oil component, plasticizer, stabilizing balancer and penetrating agent respectively according to the proportion; then place all the weighed four components in an open stainless steel container, heat up Maintain a constant temperature at 140°C, use a high-speed stirring dis...

Embodiment 2

[0039]The dosage of each raw material in this embodiment is as follows (parts by weight, the total mass is 100 g): 40 g of light base oil, 30 g of plasticizer, 25 g of stabilizing and balancing agent, and 5 g of penetrating agent. Wherein the light base oil is furfural extract oil (the mass loss of light base oil is 0.6% after the rotating film aging test; the viscosity ratio before and after aging is 1.4), the additive component is epoxy soybean oil, and the stabilizing balancer is rich in Colloid heavy oil (mass content of colloid is 95%), penetrating agent is xylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com