A kind of preparation method of large particle size cubic precipitated calcium carbonate

A precipitated calcium carbonate, cubic technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of difficult to meet the comprehensive needs of industrial production and application markets, and can not effectively control the aging The degree of improvement, the improvement of particle dispersion and other issues, to achieve the effect of low production cost, good economic benefits, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

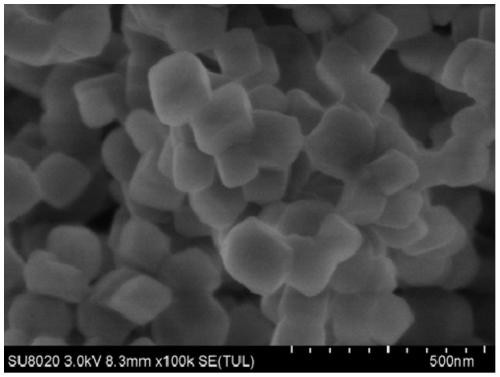

[0035] The invention discloses a method for preparing large-diameter cubic precipitated calcium carbonate, which comprises the following steps:

[0036] Step 1. After the milk of lime is refined and aged for 36-48 hours, the specific gravity of the milk of lime is adjusted to 1.050-1.065, the temperature is adjusted to 15-20°C, and then transported to a carbonization reaction kettle with stirring function. The volume of the carbonization reaction kettle is 50 cubic meters, and the filling coefficient of the carbonization reaction kettle is 0.65-0.85.

[0037] Step 2: Put the purified and cooled lime kiln gas into the carbonization reaction kettle to make the milk of lime undergo carbonation reaction in the carbonization reaction kettle. 3 / min, the volume content of carbon dioxide in the lime kiln gas is 25-35%, when the conductivity of the reaction system drops to 0.5ms / cm, the carbonization reaction is stopped, and the specific surface area (BET) of the obtained calcium carb...

Embodiment 1

[0043] In the preparation process of this embodiment, the parameters adopted are as follows:

[0044] Step 1. After the milk of lime is refined and aged for 40 hours, adjust the specific gravity of the milk of lime to 1.050, adjust the temperature to 15°C, and then transfer it to a carbonization reactor with a stirring function. The volume of the carbonization reactor is 50 cubic meters m, the filling factor of the carbonization reactor is 0.75.

[0045] Step 2: Feed the purified and cooled lime kiln gas into the carbonization reaction kettle, so that the milk of lime undergoes carbonation reaction in the carbonization reaction kettle, and the flow rate of the kiln gas is 1200m 3 / min, the volume content of carbon dioxide in the lime kiln gas is 30%, when the conductivity of the reaction system drops to 0.5ms / cm, the carbonization reaction is stopped, and the specific surface area (BET) of the obtained calcium carbonate is 43.7m 2 / g.

[0046] Step 3: In the calcium carbonat...

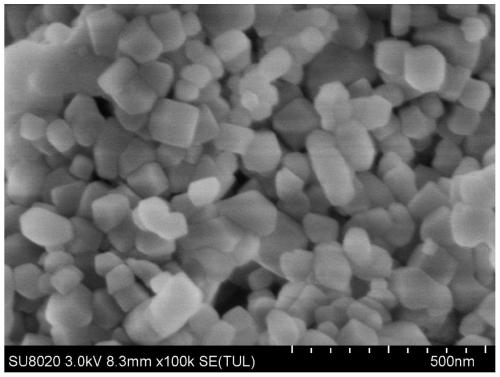

Embodiment 2

[0049] In the preparation process of this embodiment, the parameters adopted are as follows:

[0050] Step 1. After the milk of lime is refined and aged for 40 hours, adjust the specific gravity of the milk of lime to 1.060, adjust the temperature to 18°C, and then transfer it to a carbonization reactor with a stirring function. The volume of the carbonization reactor is 50 cubic meters m, the filling factor of the carbonization reactor is 0.75.

[0051] Step 2: Feed the purified and cooled lime kiln gas into the carbonization reaction kettle, so that the milk of lime undergoes carbonation reaction in the carbonization reaction kettle, and the flow rate of the kiln gas is 1200m 3 / min, the volume content of carbon dioxide in the lime kiln gas is 30%, when the conductivity of the reaction system drops to 0.5ms / cm, the carbonization reaction is stopped, and the specific surface area (BET) of the obtained calcium carbonate is 32.4m 2 / g.

[0052] Step 3: In the calcium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com