Method for improving descending stability of compression material box for construction site waste

A technology of garbage compression and stability, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of inconvenience of workers, increase the number of garbage trucks, etc., to reduce maintenance frequency, improve descending stability, and reduce vibration amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

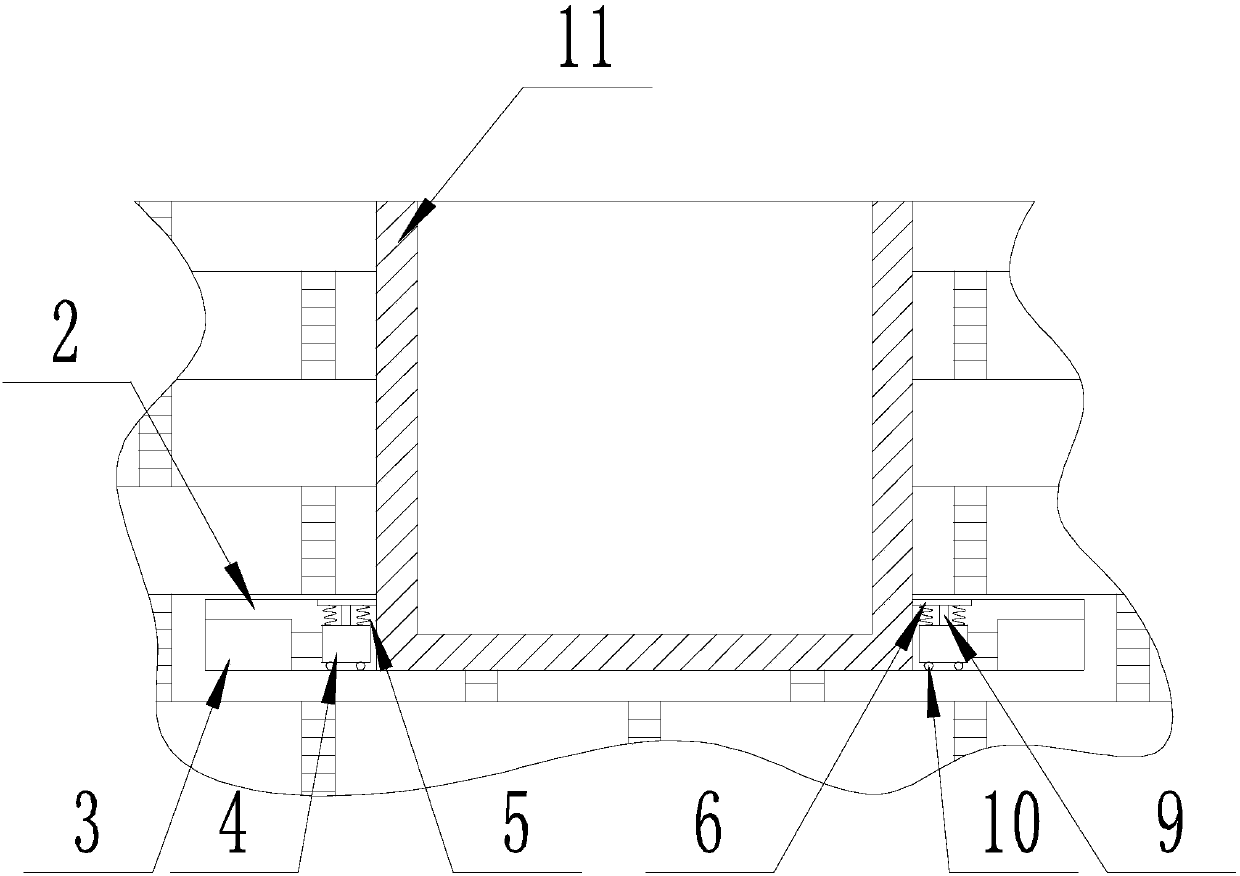

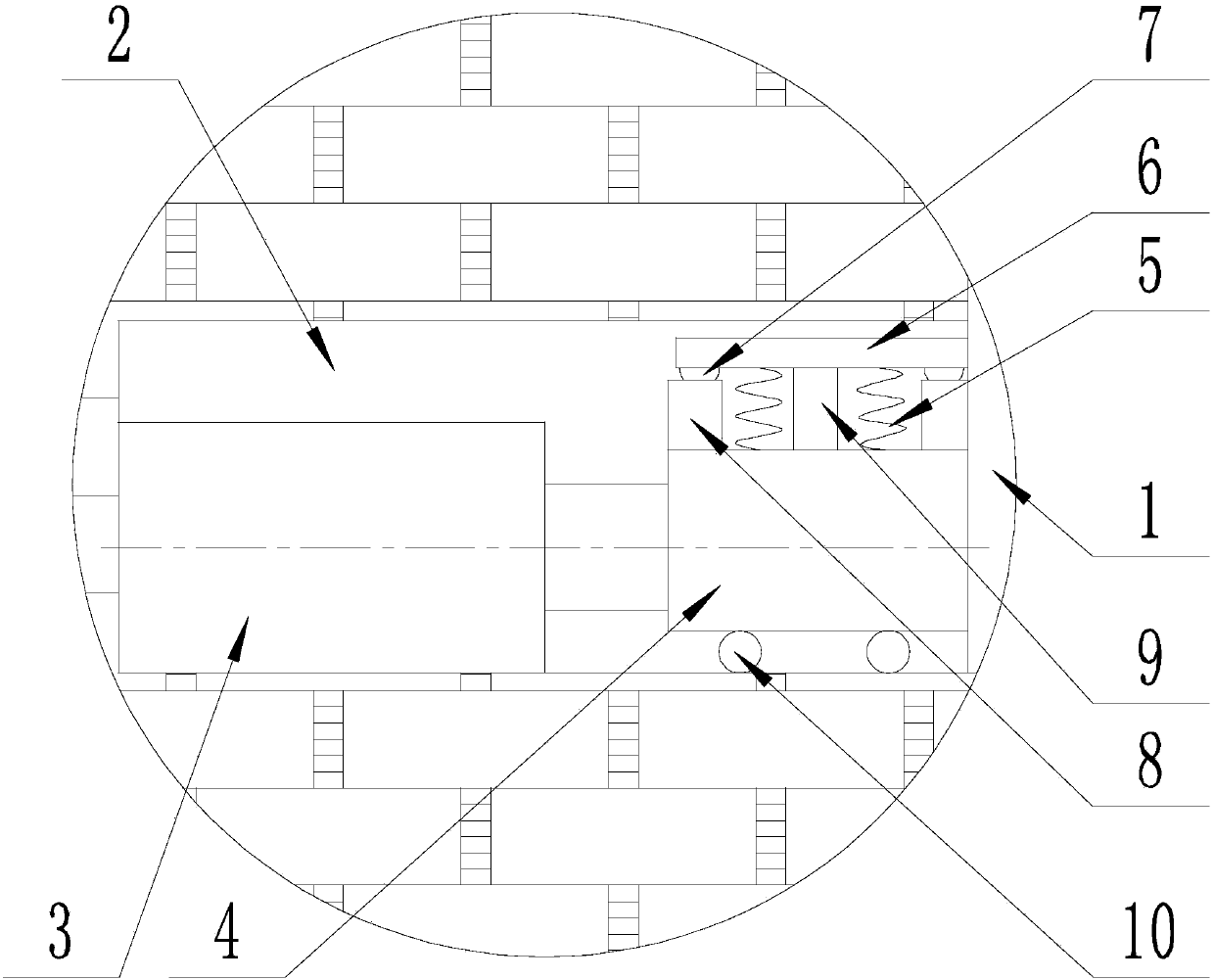

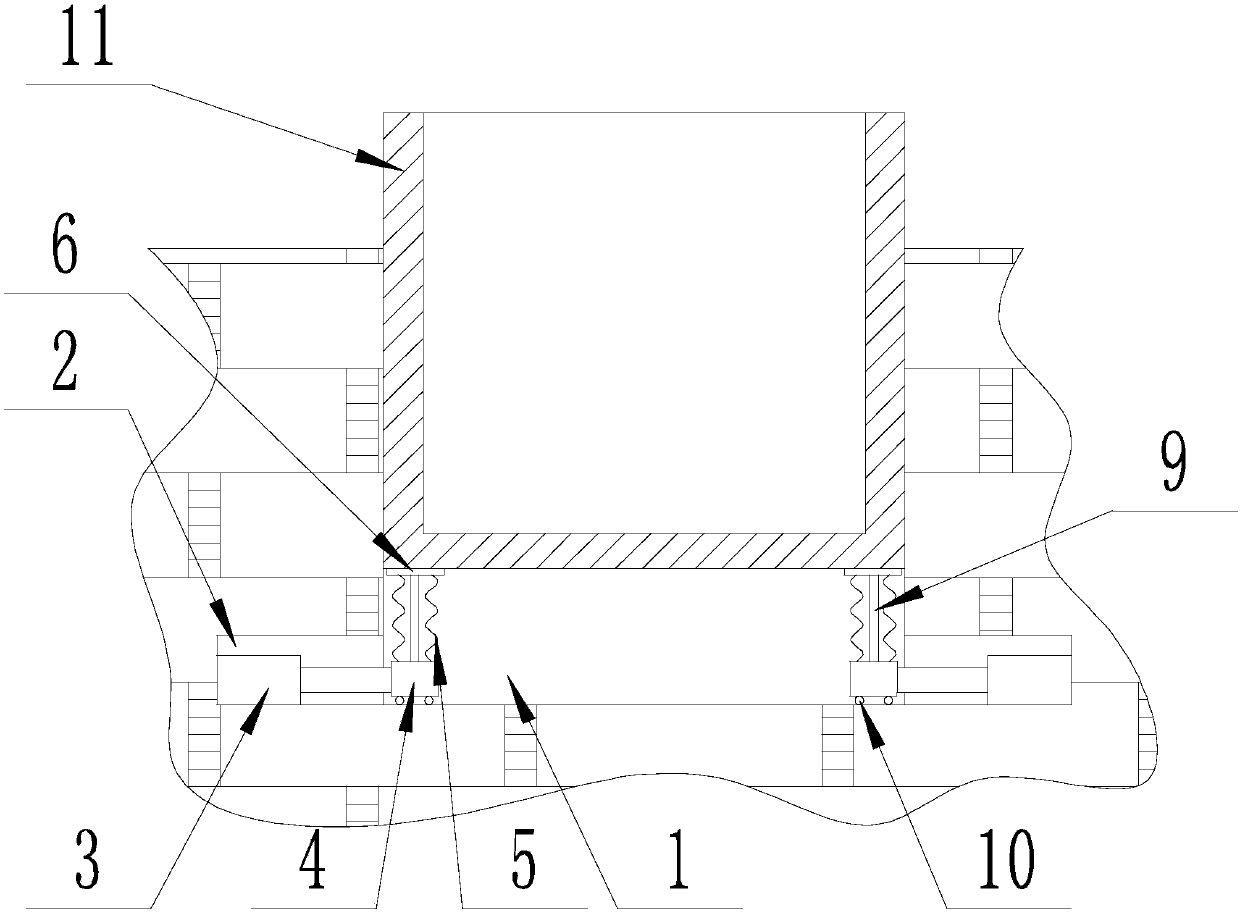

[0040] Such as Figure 1-Figure 4 Shown, the present invention improves the method for the descending stability of the rubbish compression hopper of construction site, comprises the steps:

[0041] Step A: Install the buffer assembly in the installation hole 2 of the groove 1, the buffer assembly includes a linear drive mechanism 3, a connecting seat 4 and a spring 5 connected in sequence, one end of the drive mechanism 3 is connected to the installation hole 2 The bottom of the hole is connected, and the other end of the driving mechanism 3 is connected to the connecting seat 4; one end of the spring 5 is connected to the upper surface of the connecting seat 4, and the axis of the spring 5 is perpendicular to the upper surface of the connecting seat 4;

[0042] Step B: When the material box 11 is lowered, start the driving mechanism 3, so that the connecting seat 4 moves toward the groove 1 along the wall of the mounting hole 2, until the connecting seat 4 moves into the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com