Moving blade set of turbomachine

A technology for moving blades and turbines, which is applied in the directions of machines/engines, blade supporting elements, mechanical equipment, etc., and can solve problems such as cracks in moving blades and breaking of supporting fins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

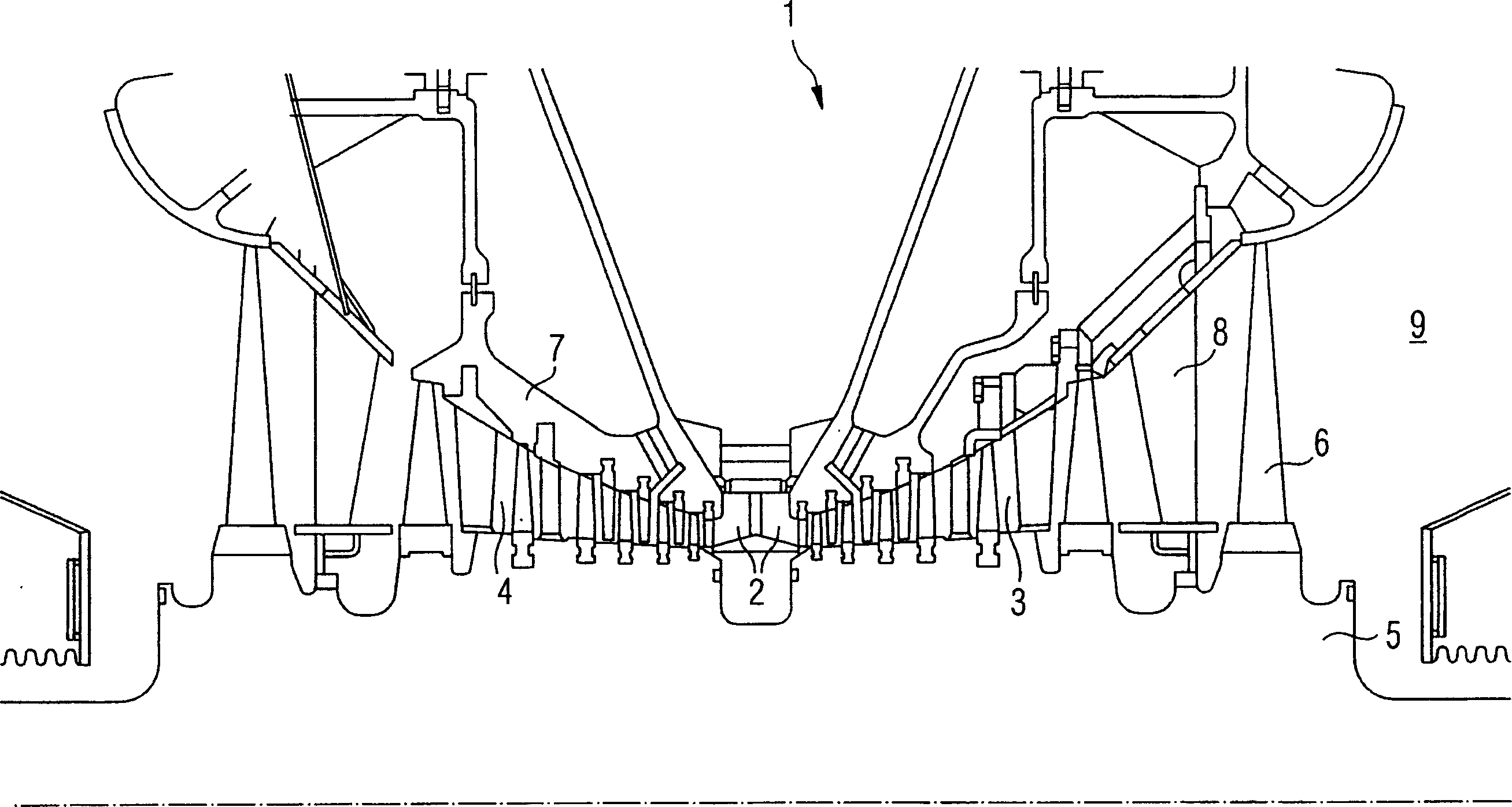

[0023] figure 1 A partial section of a low-pressure steam turbine 1 is depicted. A flow medium flows through the flow channels 3 , 4 after passing through the inflow region 2 . A rotatably mounted rotor 5 has different rotor blade sets spaced apart from one another in the axial direction, of which only one rotor blade set 6 is designated with reference numeral 6 for the sake of clarity. Guide vanes 8 are mounted on the inner housing 7 . The expanded steam is discharged from the low-pressure steam turbine 1 via the outflow line 9 . During operation of the steam turbine, the rotor 5 rotates about the axis of rotation 10 .

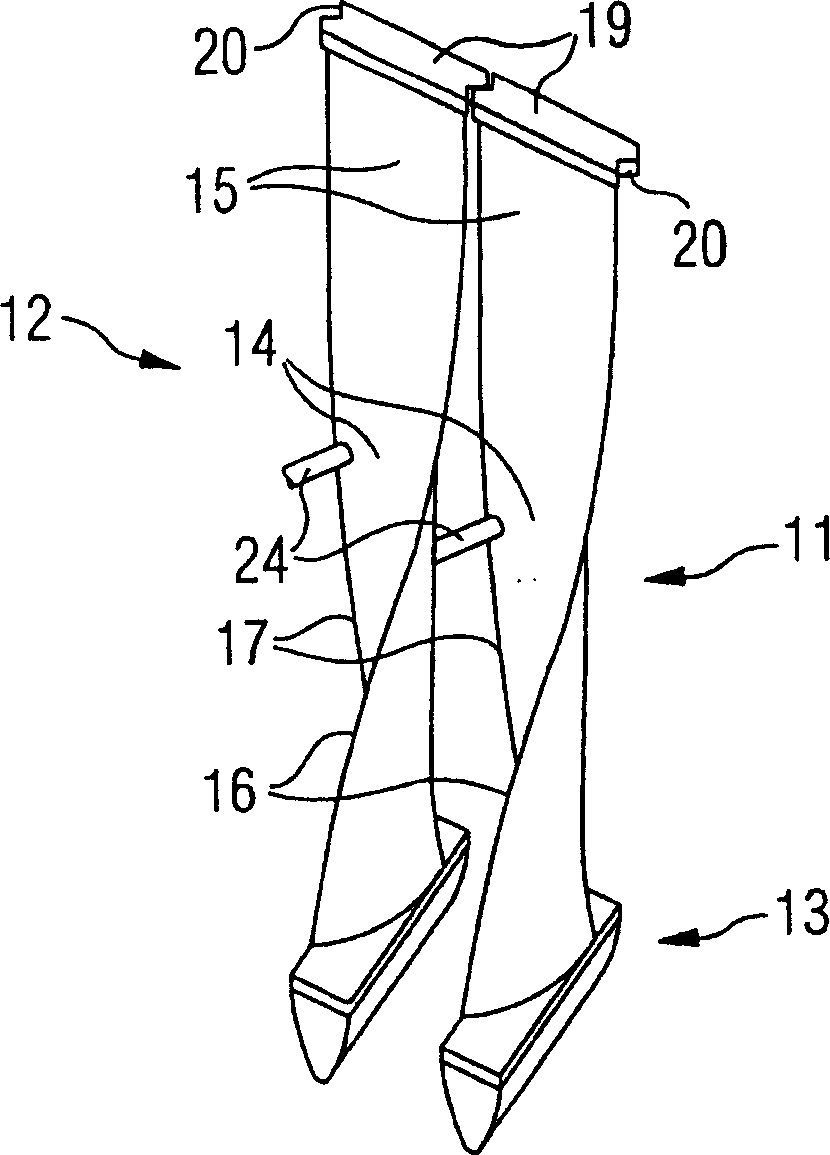

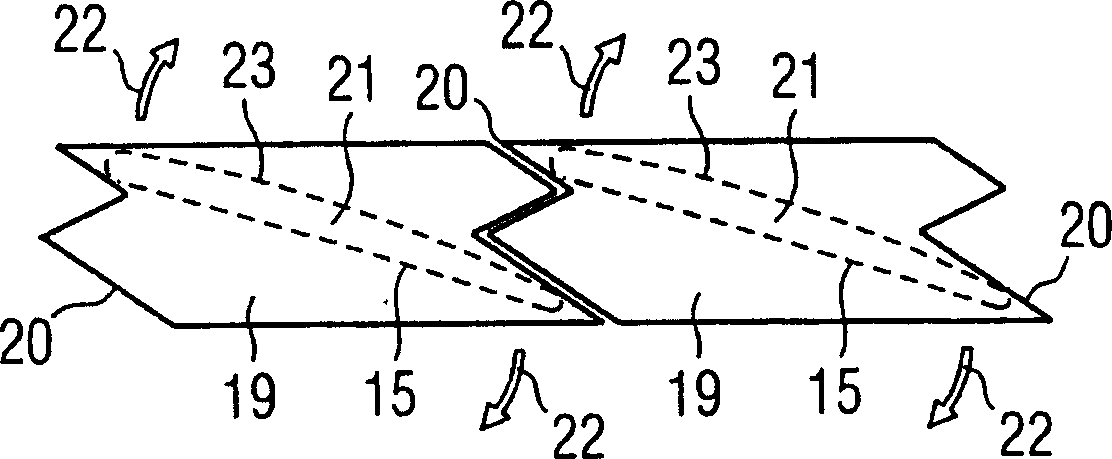

[0024] figure 2 Two rotor blades 11 , 12 of a rotor blade set 6 are depicted. The rotor blades 11 , 12 have a rotor blade root 13 , a rotor blade center 14 and a rotor blade end 15 . Furthermore, the rotor blades 11 , 12 have a leading edge 16 and a trailing edge 17 . A vertical cover plate 19 perpendicular to the radial direction 18 of the moving bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com