Method and device for compressing granular materials

A compaction device, a technology for granular materials, applied in material forming presses, presses, fluids utilizing vibration, etc., can solve problems such as insufficient use of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

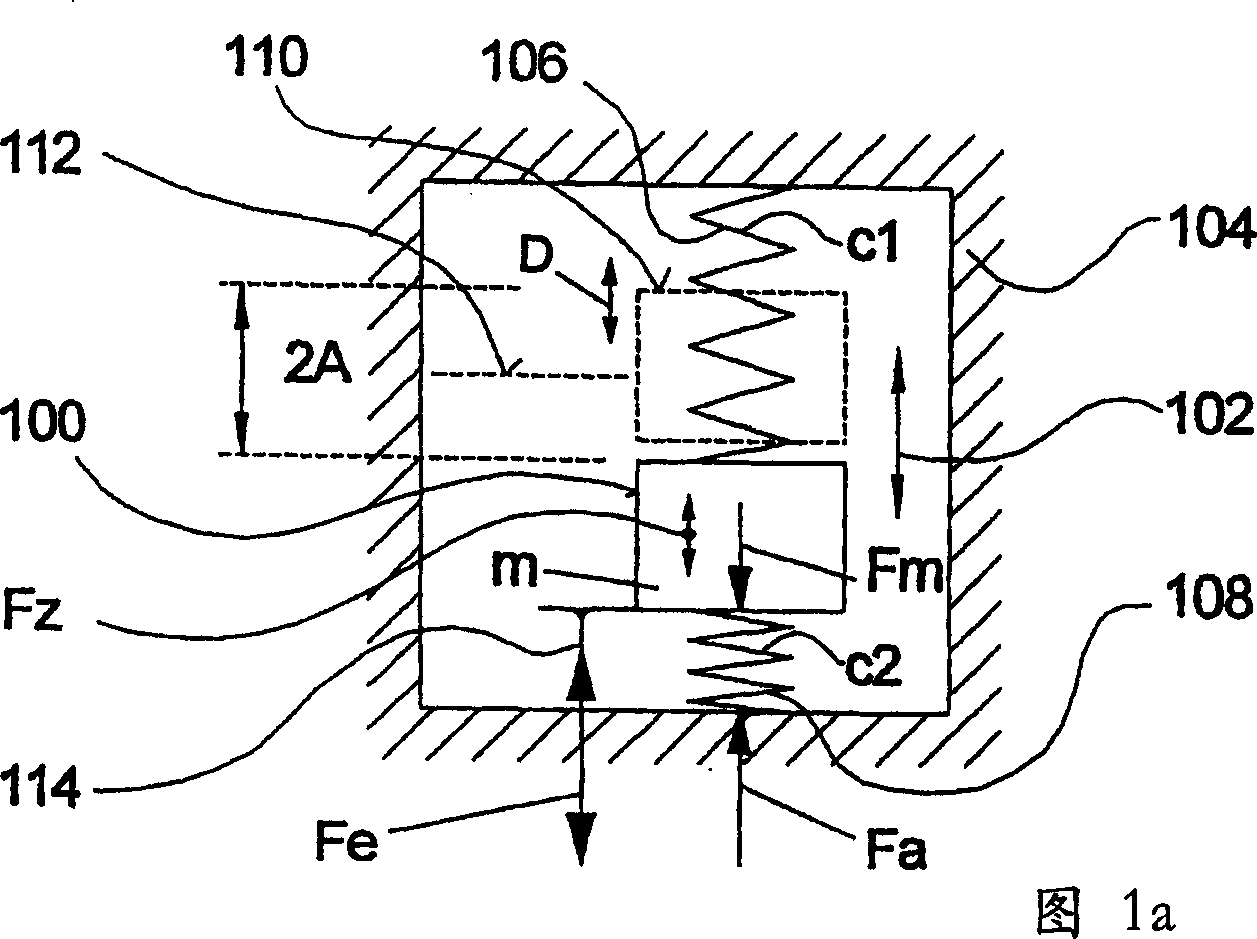

[0013] FIG. 1 a shows an oscillating mass-spring system that can be used in a resonant vibrator for carrying out the method according to the invention.

[0014] Rectangle 100 represents system mass “m” vibrating in the direction indicated by double-headed arrow 102 . The mass is supported on a frame 104 by two springs, more precisely by springs of stiffness C 1 The upper spring 106 and the spring rate is C 2 The lower spring 108 supports. The rectangle 100 representing the mass m has two positions which represent the opposite positions of the vibratory motion. The position of the upper line 110 represents the sum 2A of the two vibration amplitudes A. When upper thread 110 is at position 112, it is an intermediate position. The exciter actuator required for the exciter is indicated by the double-headed arrow 114, while Fe indicates the force amplitude of the harmonically excited vibration acting on the mass m.

[0015] In one instance, spring 108 may be a compressed extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com