Coating device and coating method

A coating device and coating liquid technology, applied in the field of coating technology, can solve problems such as lack of liquid, insufficient coating liquid, limitation of coating speed and conveying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

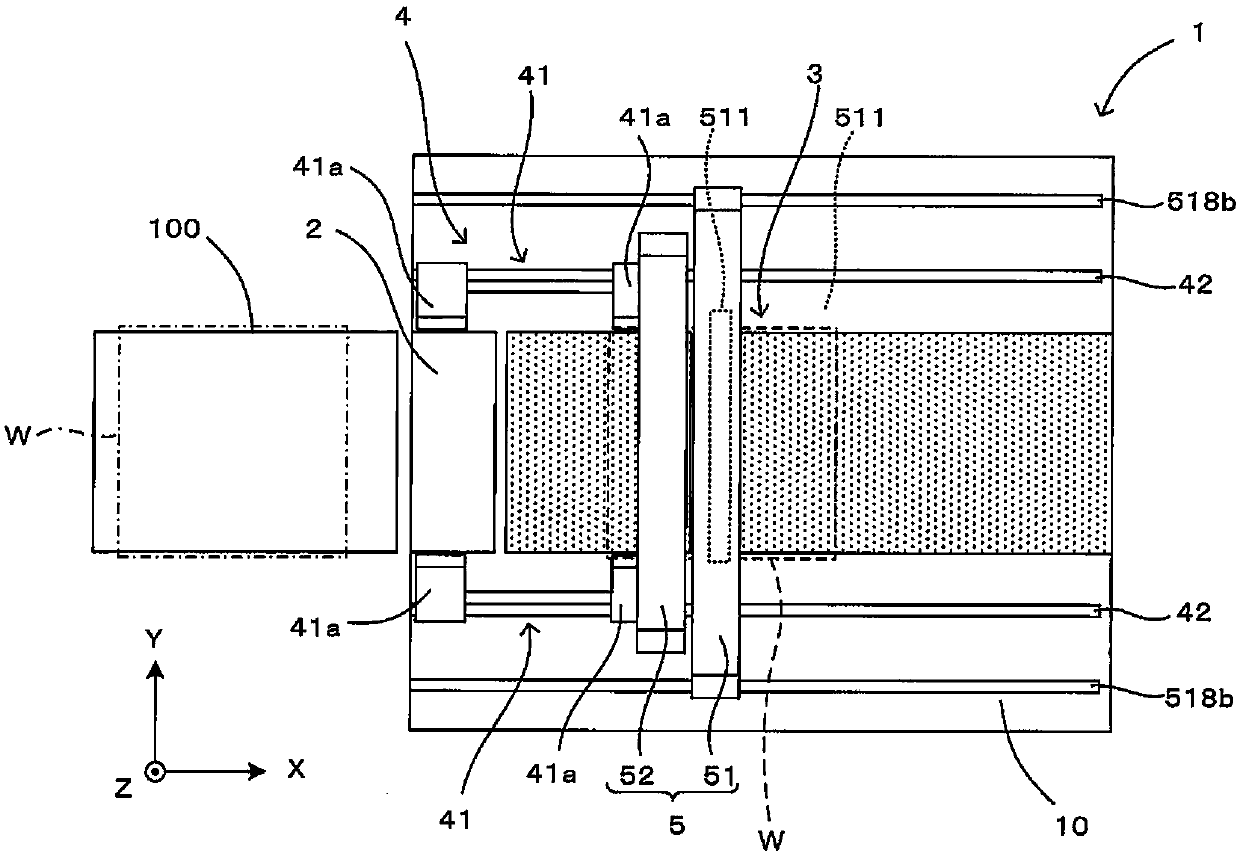

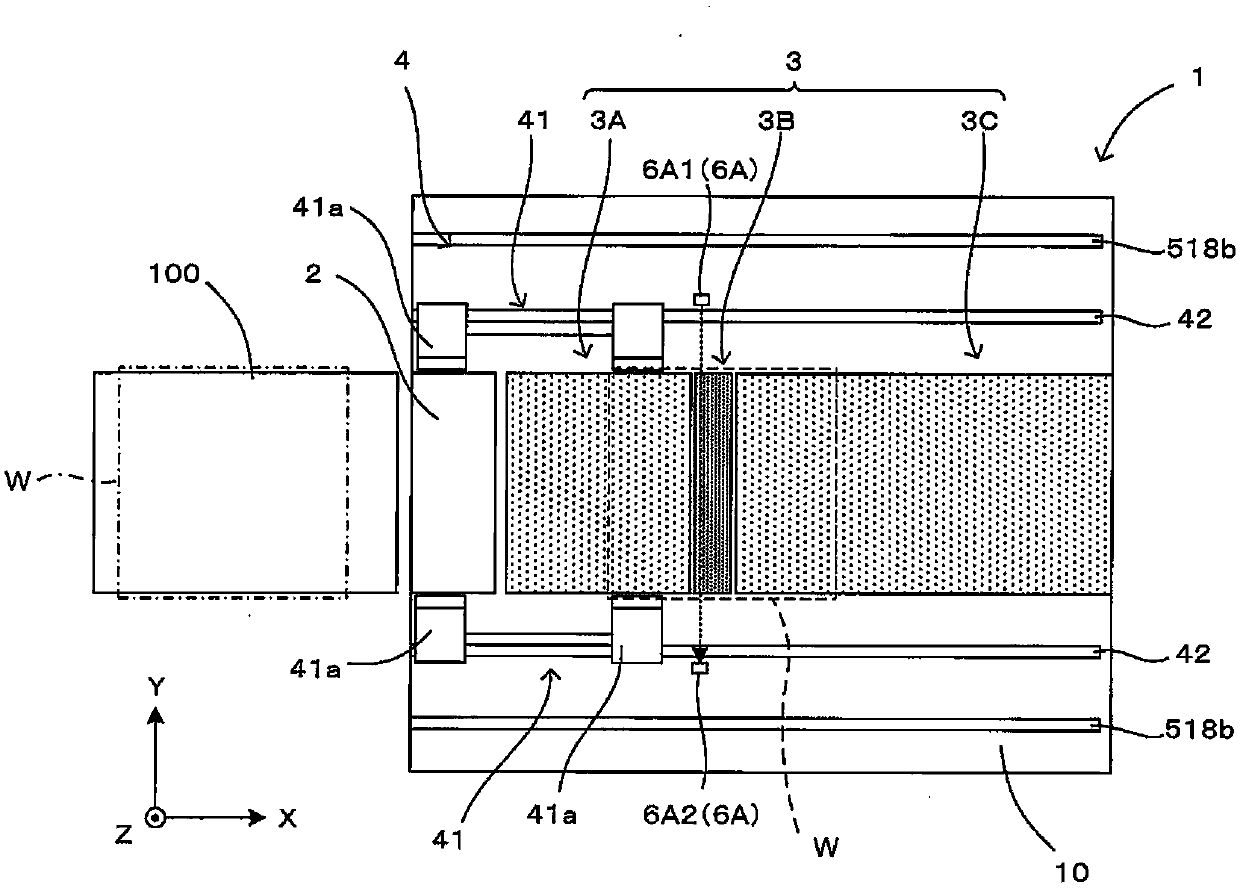

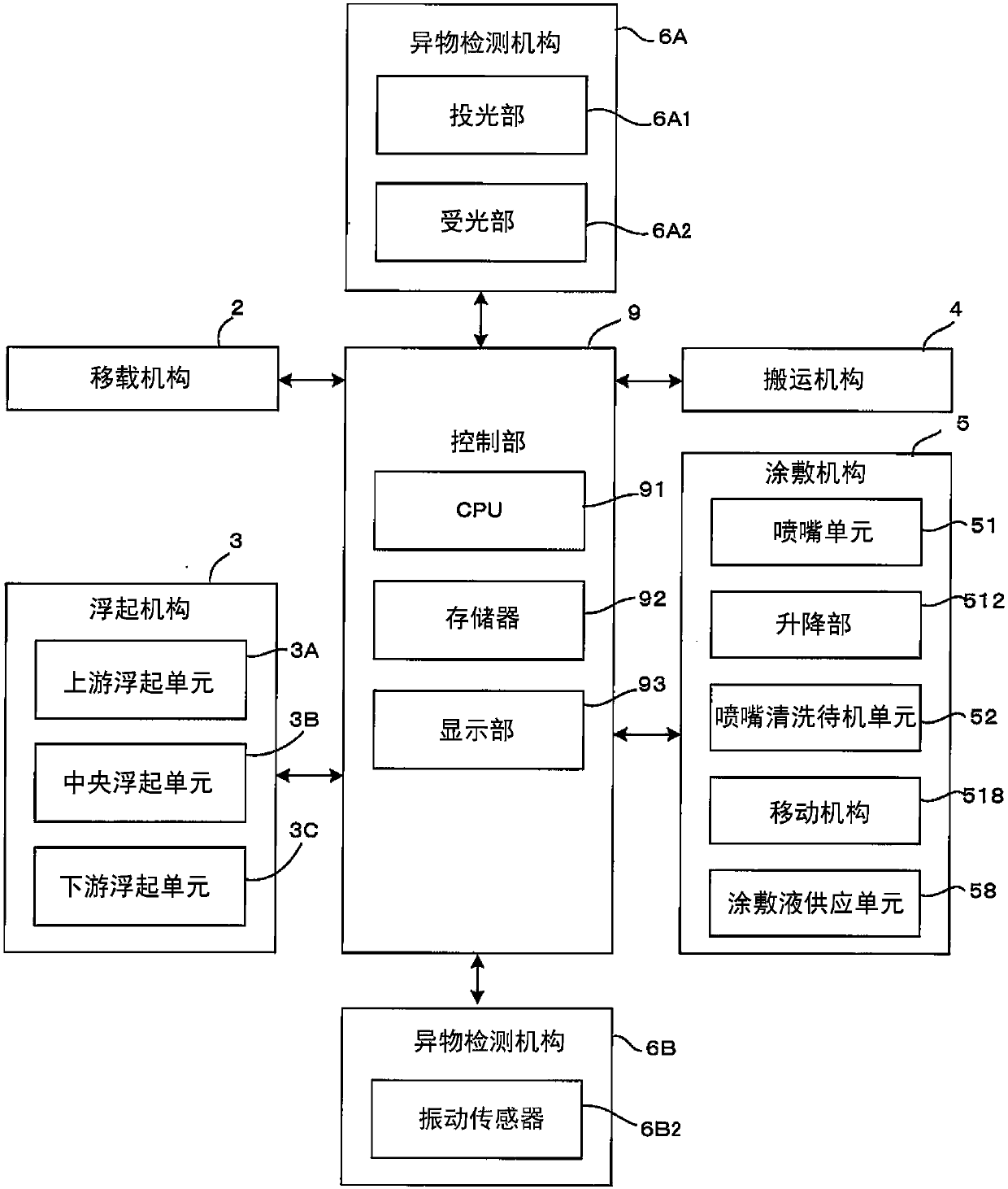

[0034] Figure 1A It is a figure which shows one embodiment of the coating apparatus of this invention, and is a plan view seen from vertically above, and Figure 1B From Figure 1A Top view with applicator disassembled. also, figure 2 is showing control Figure 1A A block diagram of the control mechanism of the coating device shown. In addition, in Figure 1A , Figure 1B And in each figure described later, in order to clarify the arrangement relationship of each part of the device, the conveyance direction of the substrate W is referred to as the "X direction", and the Figure 1A , Figure 1B The horizontal direction from the left-hand side to the right-hand side is called "+X direction", and the opposite direction is called "-X direction". In addition, in the horizontal direction Y perpendicular to the X direction, the front side of the device is referred to as "−Y direction", and the rear side of the device is referred to as "+Y direction". In addition, the upward dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com