Comprehensive utilization method for clammy waste

A waste and sticky wet technology, which is applied in the fields of energy saving and environmental protection, can solve the problems of complex drying system links, unsatisfactory application effects, and high maintenance costs in the later period, so as to avoid difficult utilization, increase production capacity and economic benefits, and reduce maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following sticky and wet waste is a specific embodiment of coal slime, and in conjunction with the accompanying drawings, the treatment of coal slime as an example is described in detail as follows:

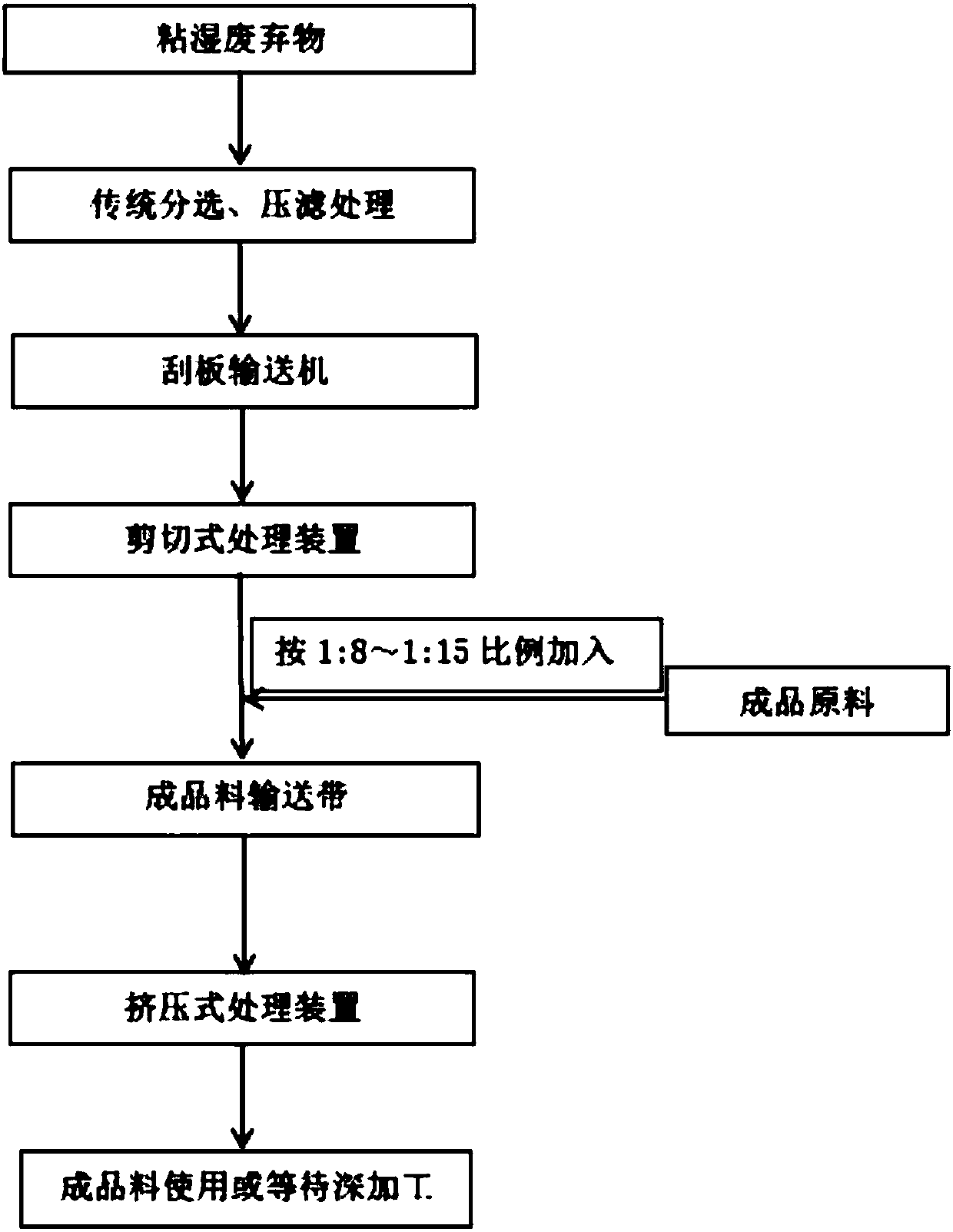

[0022] refer to figure 1 This process includes the traditional sorting filter press, scraper conveying, shearing treatment, conveyor belt conveying, finished material blending, extrusion treatment links,

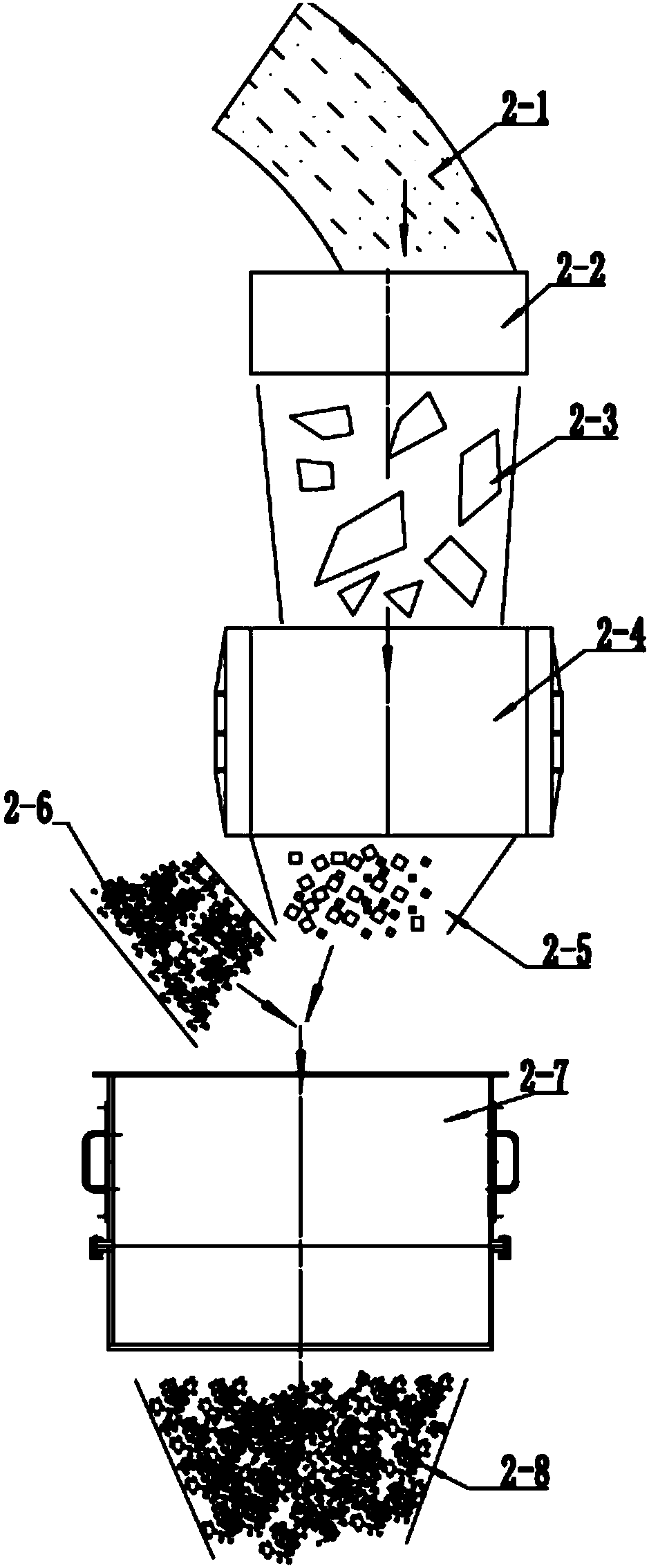

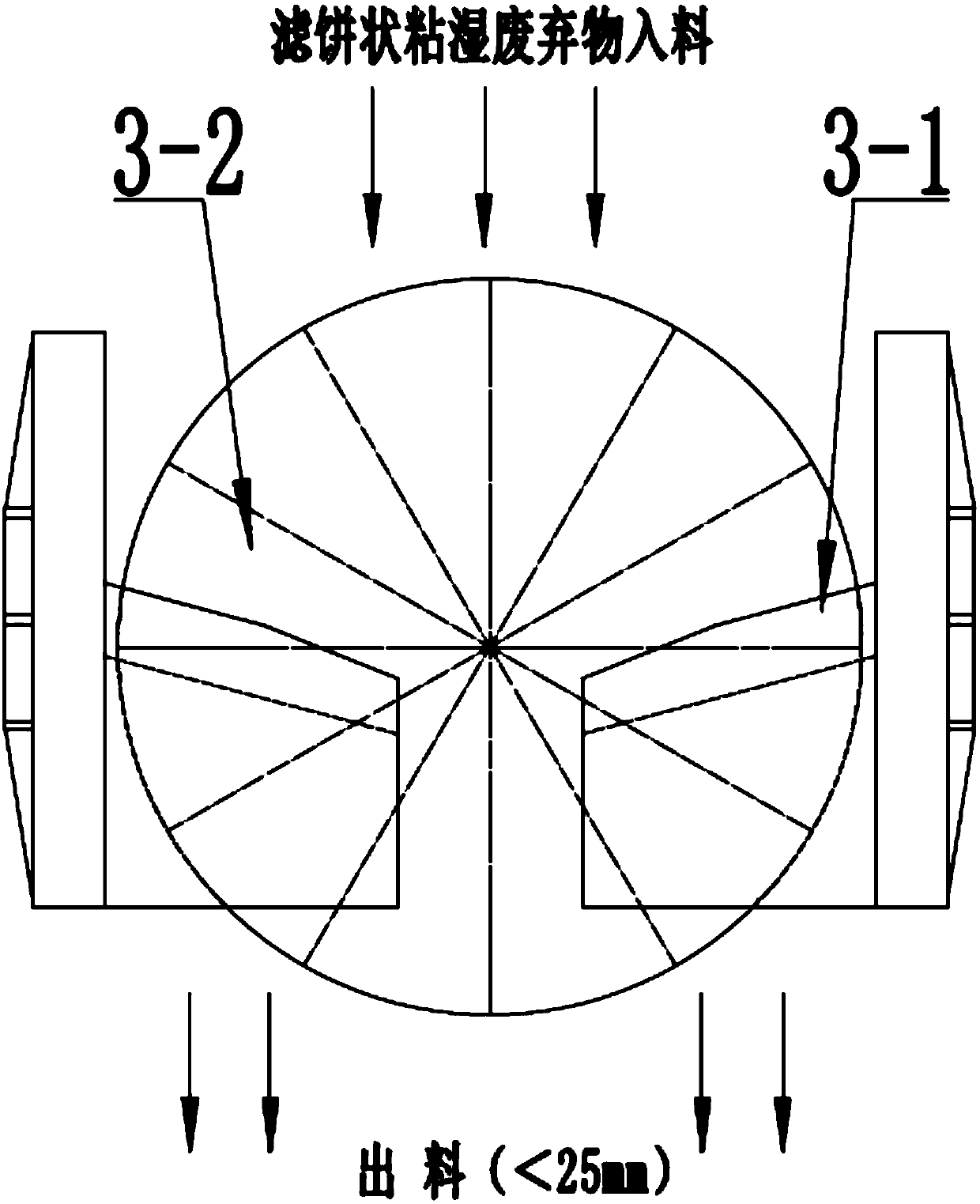

[0023] refer to figure 2 Coal slime water 2-1 is processed by sorting machine and filter press 2-2 to form coal slime filter cake 2-3. Coal slime filter cake 2-3 has different sizes and large particle sizes. Coal slime filter cake 2-3 It is transported by the scraper to the shearing treatment device 2-4, and after secondary pulverization, the slime filter cake becomes the secondary medium granular product 2-5, and the particle size of the secondary medium gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com