Wafer adhesive remover

A technology of wafer and gluing machine, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of backward glue removal equipment technology, easily damaged devices, and unclean cleaning, so as to facilitate sales and reduce costs. Cleaning cost, fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

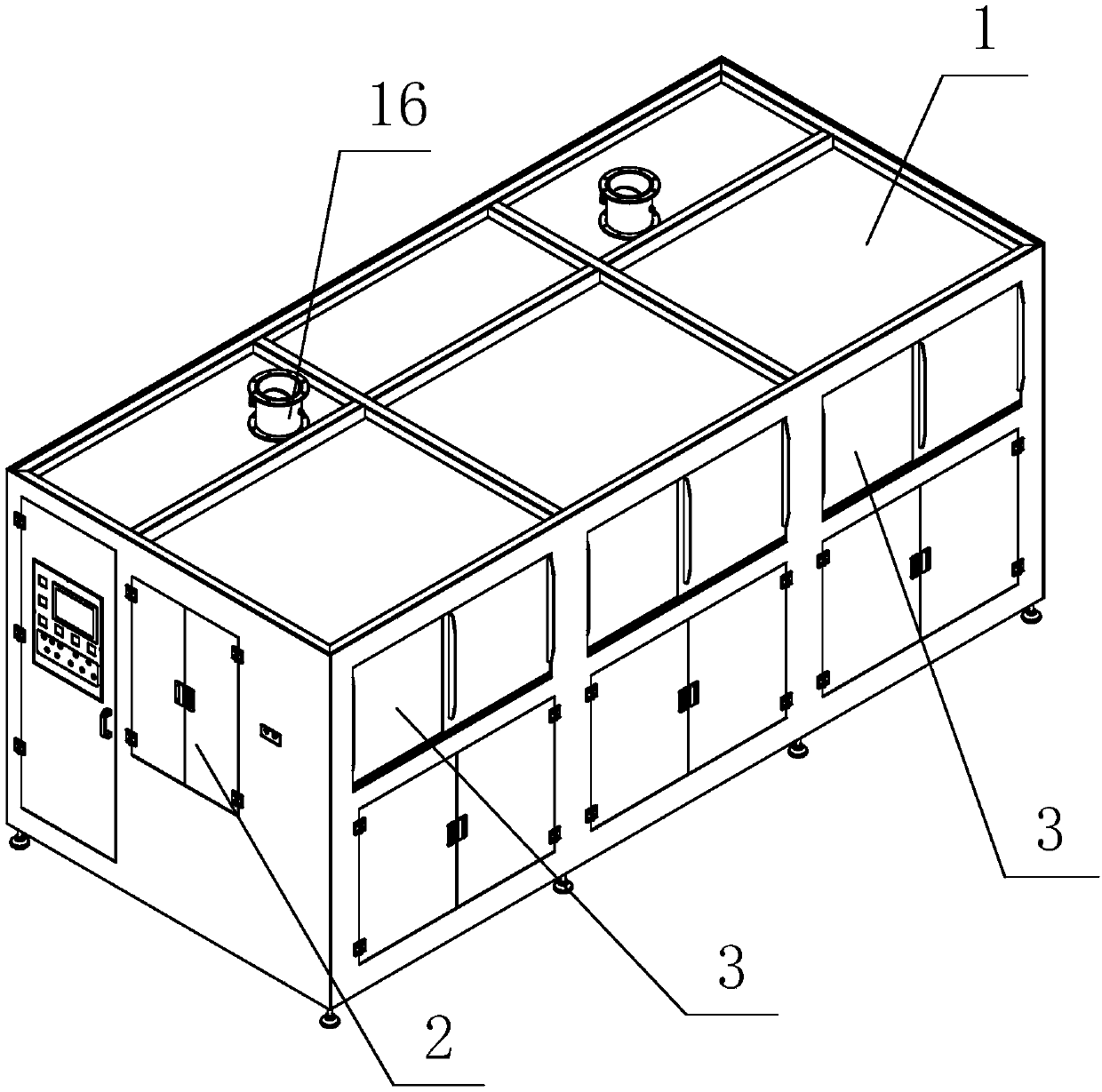

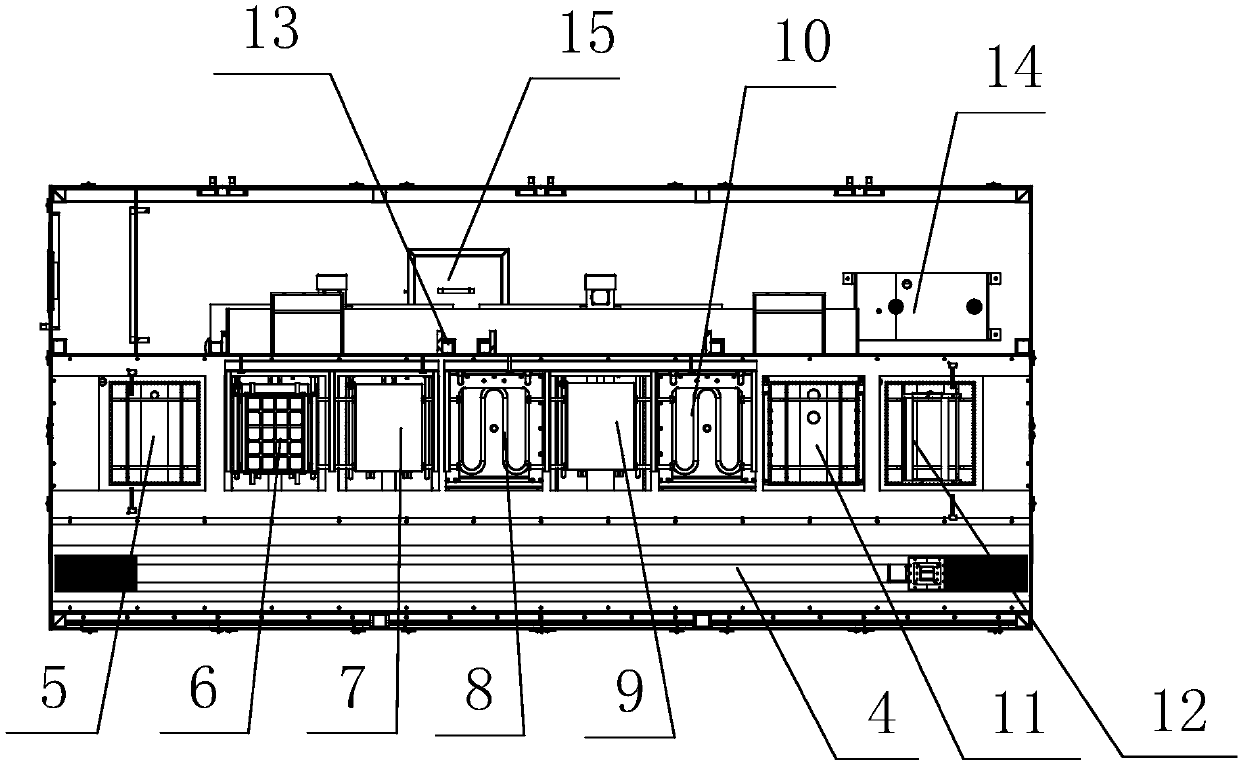

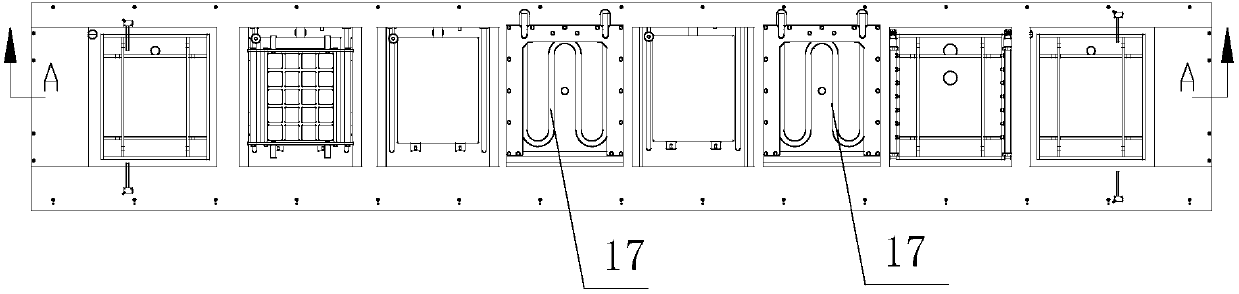

[0032] like figure 1 and Figure 4 A wafer removing machine shown includes a body 1, the side of the body 1 is provided with a workpiece flower basket inlet 2, a discharge port and a control box, and the front of the body 1 is provided with a perspective window 3, and the side of the body 1 is provided with a perspective window 3. The main body 1 is provided with a cleaning tank and a manipulator device 4. The manipulator device 4 automatically puts the flower basket of the workpiece into the cleaning tank for cleaning, and then transfers it to the next cleaning tank for cleaning. The cleaning tank includes the first water tank 5 arranged in sequence. , Ultrasonic drug tank 6, first ultrasonic rinse tank 7, first acid tank 8, second ultrasonic rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com