Ring piece automatic multi-frequency array ultrasonic nondestructive testing device and method

A non-destructive testing and ring technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of quantitative detection of difficult defects, low detection efficiency, and detection blind spots Large and other problems, to achieve the effect of good coupling effect, simple operation, and fast scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

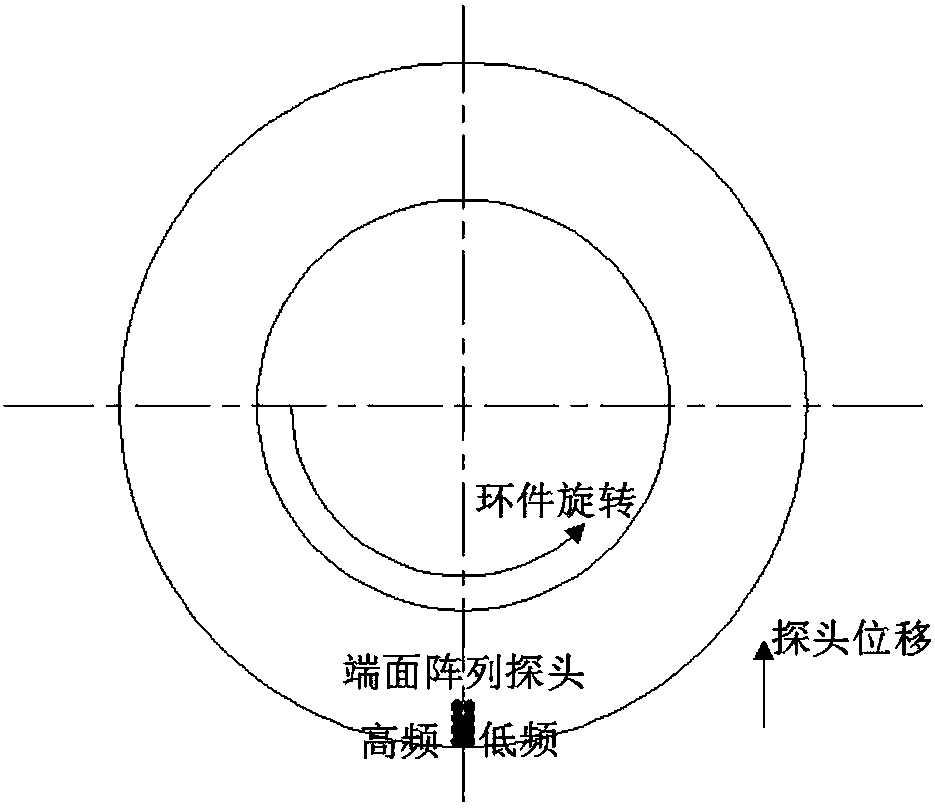

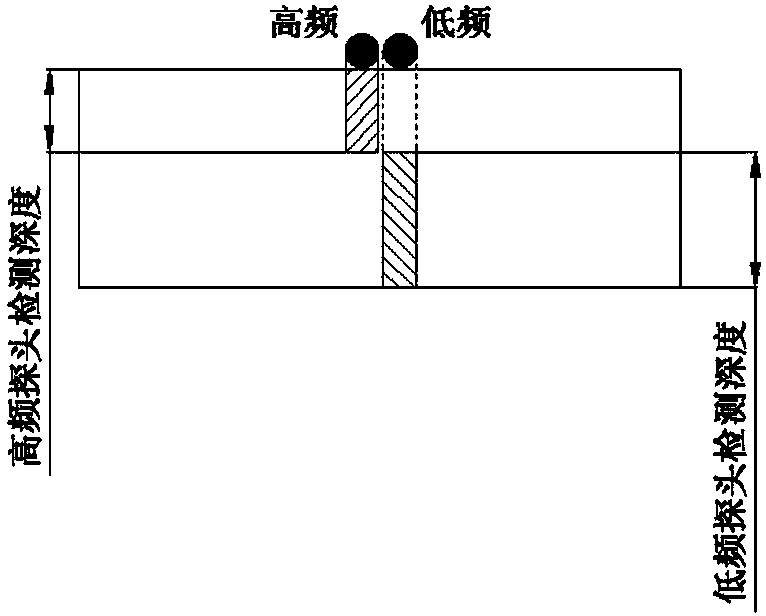

[0028] In a preferred embodiment of the present invention, as figure 1 As shown, an automatic multi-frequency array ultrasonic non-destructive testing device for ring parts includes a collection tank 16 equipped with a couplant (water is used as the couplant in this embodiment), a rotary detection platform 14 arranged in the collection tank 16, and a driving rotary The R-axis servo motor 13 that the detection platform 14 rotates around its own axis, the axial linear module 18, the axial servo motor that drives the axial linear module 18 to move axially along the rotary detection platform 14, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com