Construction method of dense sandstone multi-scale pore model and application

A dense sandstone, multi-scale technology, applied in the direction of suspension and porous material analysis, measuring devices, scientific instruments, etc., can solve the problems of scarcity of instruments, time-consuming, and restrictions on the universal use of Nano-CT systems, and achieve easy implementation and technical advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

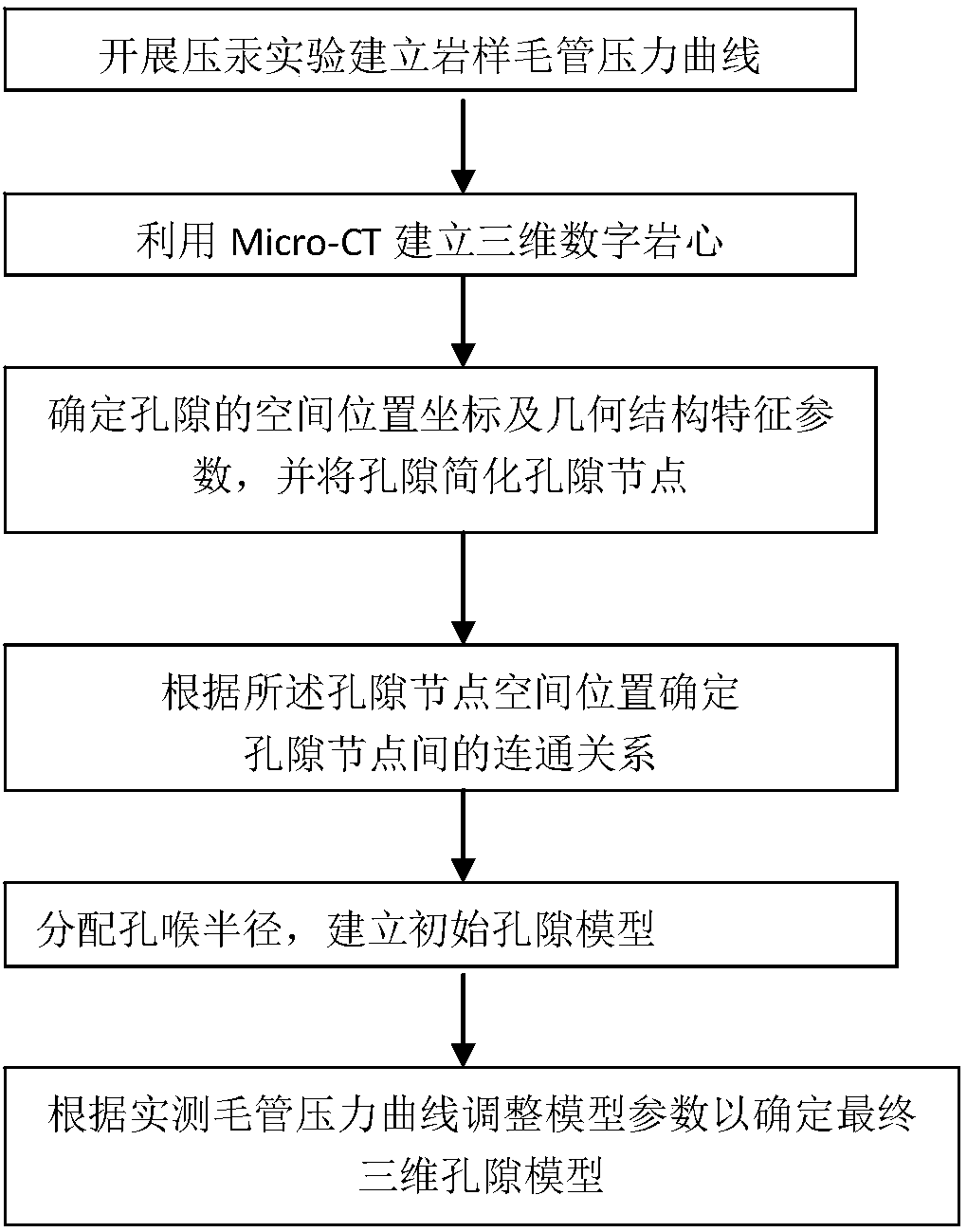

[0095] This embodiment is used to illustrate the construction method of the tight sandstone multi-scale pore model of the present invention, and its flow is as follows figure 2 shown.

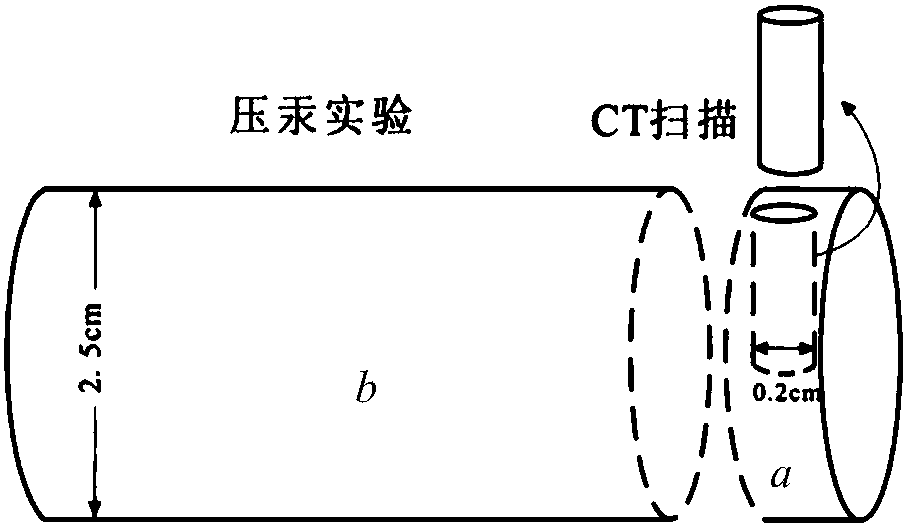

[0096] The brown-gray fine-grained lithic sandstone samples of the tight sandstone gas field are figure 1 way to split. One of them was used for the mercury injection test described below, and the other was used for the Micro-CT scan described below.

[0097] (1) Obtain Micro-CT images of rock samples and capillary pressure curves

[0098] a.Micro-CT scan

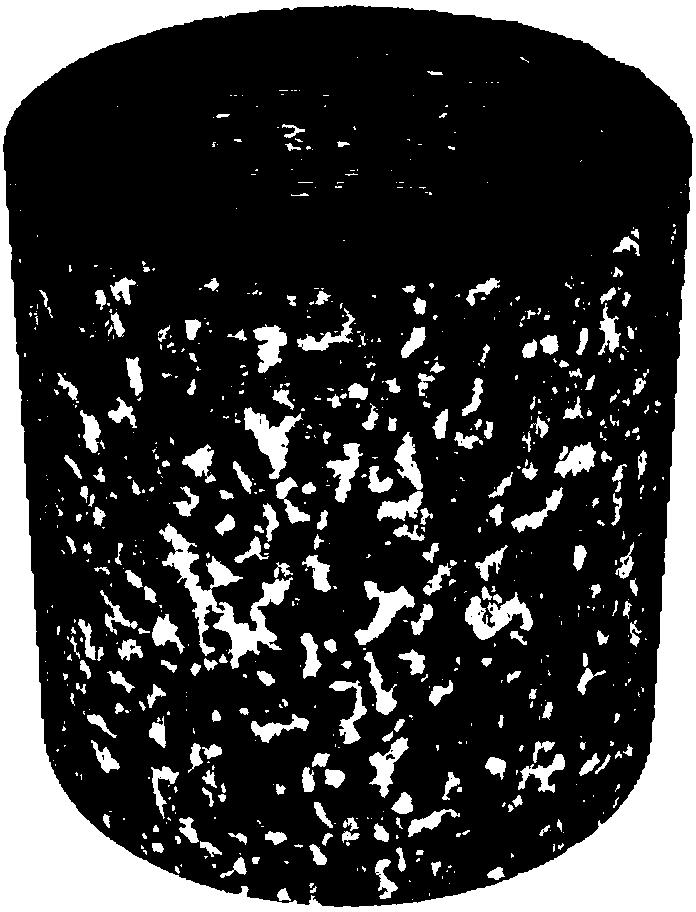

[0099] The MicroXCT-400 system of Xradia Company in the United States was used to scan the brown-gray fine-grained lithic sandstone samples of the tight sandstone gas field mentioned above. During this process, the sample stage will rotate 360 degrees and can take 1080 projection images. A three-dimensional structural image composed of 986 32-bit grayscale slice images (such as image 3 shown), the image resolution is 2.15 μm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com