Drop tower frictional wear testing device and method

A friction and wear test, drop tower technology, applied in the direction of measuring devices, mechanical devices, testing wear resistance, etc., can solve the problems of ground simulation of complex trajectory three-dimensional movement, limited practical scope of research, friction and wear is blank, etc. , to achieve the effect of simple structure, strong impact resistance and precise loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

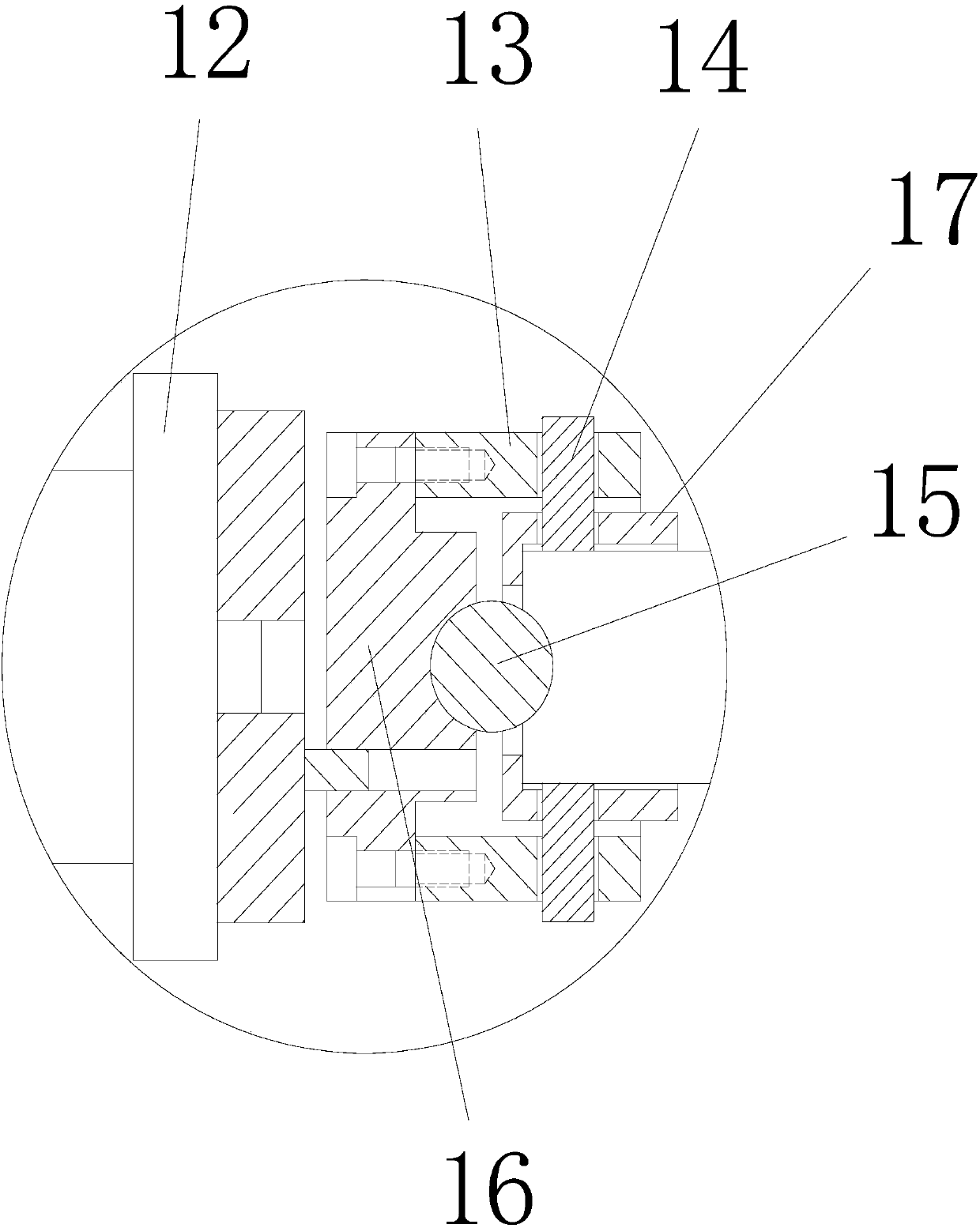

[0044] A drop tower friction and wear test device, comprising a load loading mechanism, a static sample clamping mechanism, a dynamic sample clamping mechanism, a friction power device and a frame fixedly installed in the drop tower drop chamber, the load loading mechanism, the static test The sample clamping mechanism, the dynamic sample clamping mechanism and the friction power device are arranged horizontally (horizontal) or vertically (vertical);

[0045] The frame consists of a load vertical plate, a sample fixture vertical plate and a power device vertical plate fixed in sequence. The load loading mechanism is fixed on the load vertical plate, and the static sample clamping mechanism is installed on the sample clamp vertical plate. The device is set on the power plant riser;

[0046] The load loading mechanism includes a stepper motor, a ball screw, a spring push plate, a loading spring, a spring mounting seat and a guide rail. The power output shaft of the step motor is...

Embodiment 2

[0062] This embodiment differs from Embodiment 1 in that:

[0063] In this embodiment, a friction detection mechanism is also included. The friction detection mechanism includes a baffle, a transmission plate and a friction sensor, the baffle is fixedly arranged, the transmission plate is fixedly connected to the transmission shaft, and the static sample mounting seat is installed on the transmission shaft On the end face, the friction sensor is arranged on the baffle plate or the transmission plate and is located at the position where the baffle plate and the transmission plate are in contact during the test.

[0064] Here, the friction sensor is installed on the baffle plate as an example: During the test, the transmission shaft rotates to drive the drive plate to rotate toward the baffle plate (if the drive plate and the friction sensor are already in contact, the drive plate will move toward the baffle plate. Static pressure) so that the transmission plate is in contact wi...

Embodiment 3

[0066] In this embodiment, there are two friction sensors and two baffle plates, and the two baffle plates are fixedly arranged, and the two baffle plates are parallel, the middle part of the transmission plate is fixedly connected to the transmission shaft, and the two friction sensors are respectively arranged on The baffle plate is located at the position where the two ends of the transmission plate are in contact with the two baffle plates.

[0067] The friction data detected by the pressure sensor is collected by an instrument capable of collecting data at high speed, and the friction data is stored in the chip during the test. In order to meet the requirements of rapid detection and storage, the installation of two baffles is beneficial to reduce the vibration caused by impact during the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com