Method for seed culture of Aspergillus niger and preparing citric acid

A technology of Aspergillus niger and citric acid, which is applied in the field of microbial fermentation, can solve the problems of reducing the utilization rate of seed tanks, uneven size of mycelial balls, and reducing the efficiency of cell transformation, so as to improve mass transfer and dissolved oxygen, and shorten the fermentation period. , the effect of preventing spore aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

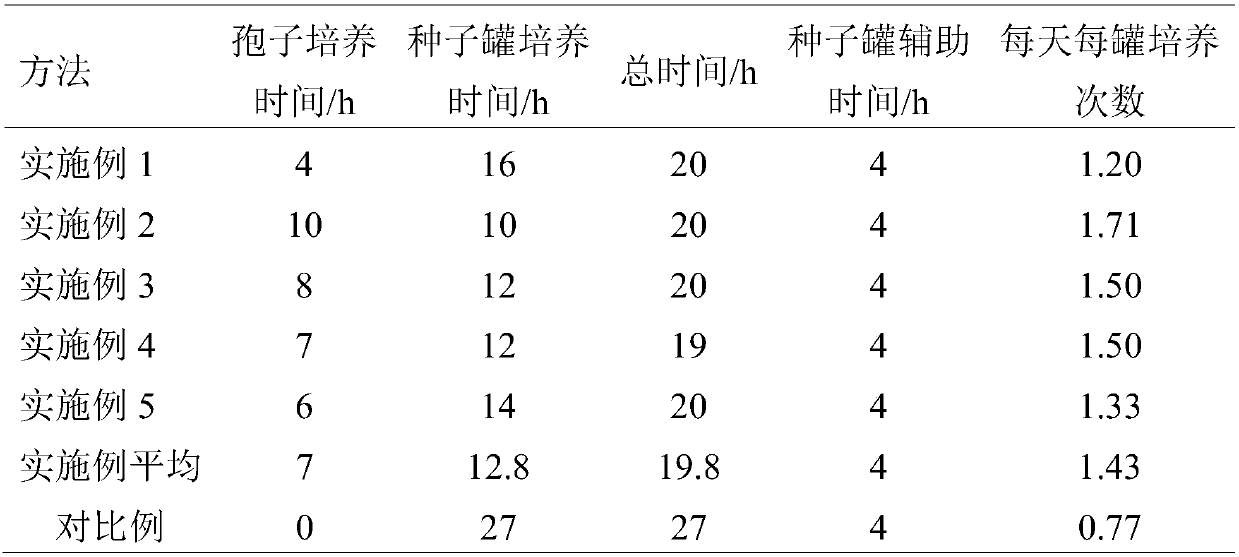

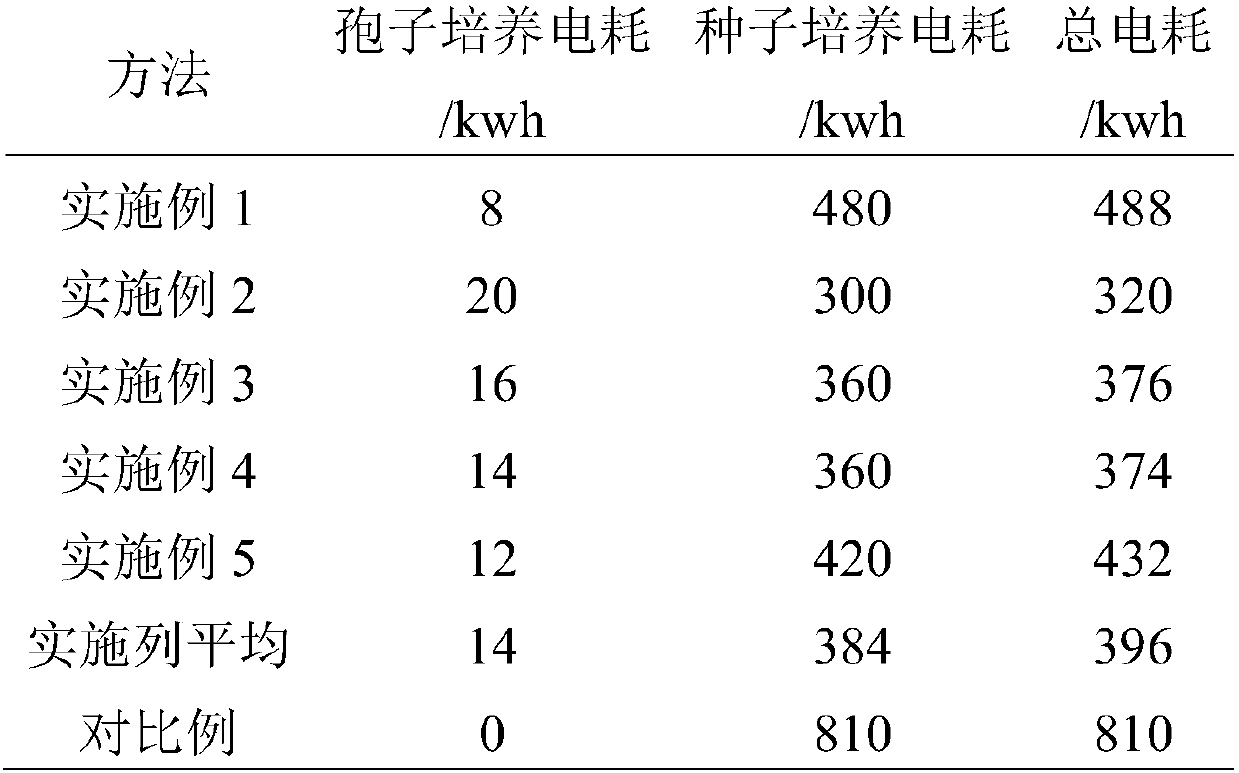

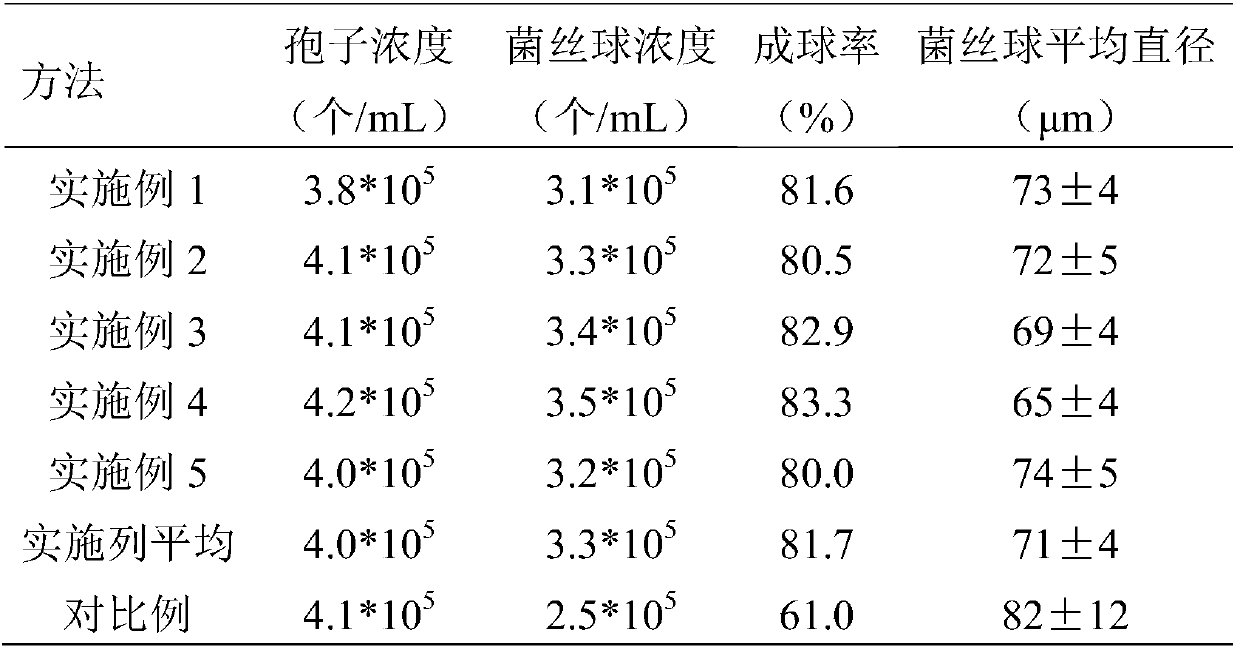

Examples

Embodiment 1

[0031] Raw material processing: After crushing the corn, pass through a 60-mesh sieve; mix the obtained corn flour and tap water in a mass ratio of 1:3, and use Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add Novozymes α-high temperature amylase according to the addition amount of 20U / g corn flour; the obtained slurry is first sprayed at 97°C, kept for 1.5h, then sprayed at 127°C, and flashed The temperature of the feed liquid is lowered to 95°C, and the temperature is kept for 1 hour. After the iodine test turns light brown, the qualified corn liquefaction liquid is obtained; 80% of the corn liquefaction liquid is filtered through a plate frame to remove the filter residue, and the sugar liquid is obtained.

[0032] Spore culture: Take the cultured mature spores of Aspergillus niger bran, add 5 times the volume of sterile water, shake and soak for 0.5h, filter with four layers of gauze to obtain a dispersed spore suspension, and filter the corn liquefaction solution throu...

Embodiment 2

[0036] Raw material processing: same as embodiment 1.

[0037] Spore culture: Take the cultured mature spores of Aspergillus niger, add 10 times the volume of sterile water, shake and soak for 12 hours, and filter with four layers of gauze to obtain a dispersed spore suspension. Dilute the sugar solution obtained by filtering the corn liquefaction solution with plate and frame with water to a total sugar concentration of 20 g / L; add starch residue to make the solid concentration reach 100 g / L; add 0.1% (v / v) volume Tween 80; Adjust the pH to 6.0; sterilize at 121°C for 15 minutes, cool to 39°C; insert the spore suspension so that the final concentration of spores is 6*10 9 cells / mL, cultivated at a temperature of 42° C. and a stirring speed of 100 rpm for 4 h, then increased the stirring speed to 1000 rpm, and stirred for 2 h to obtain a spore suspension.

[0038]Seed culture: The seed medium is prepared with corn liquefaction solution and ammonium sulfate, the total sugar co...

Embodiment 3

[0041] Raw material processing: same as embodiment 1.

[0042] Spore culture: take the mature Aspergillus niger bran spores, add 8 times the volume of sterile water, shake and soak for 6 hours, filter with four layers of gauze to obtain a dispersed spore suspension; filter the corn liquefaction solution through a plate and frame to obtain sugar solution Add water to dilute to a total sugar concentration of 10g / L, add starch residue to make the solids concentration reach 50g / L; add 0.08% (v / v) volume Tween 80, adjust the pH to 5.0, and sterilize at 121°C for 15 minutes. Cool to 39°C; insert the spore suspension so that the final concentration of spores is 4.5*10 9 cells / mL, cultivated at a temperature of 38°C and a stirring speed of 50 rpm for 8 hours, then increased the stirring speed to 500 rpm, and stirred for 1 hour to obtain a suspension of germinated spores.

[0043] Seed culture: The seed medium is prepared with corn liquefaction solution and ammonium sulfate, the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com