Closed storage warehouse

A storage warehouse, closed technology, applied in the direction of loading/unloading, storage devices, conveyor objects, etc., can solve the problems of increased civil construction costs, large civil construction investment, increased load on the roof of the warehouse, etc., to reduce construction costs, The effect of simplifying the structure of the retaining wall and high degree of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

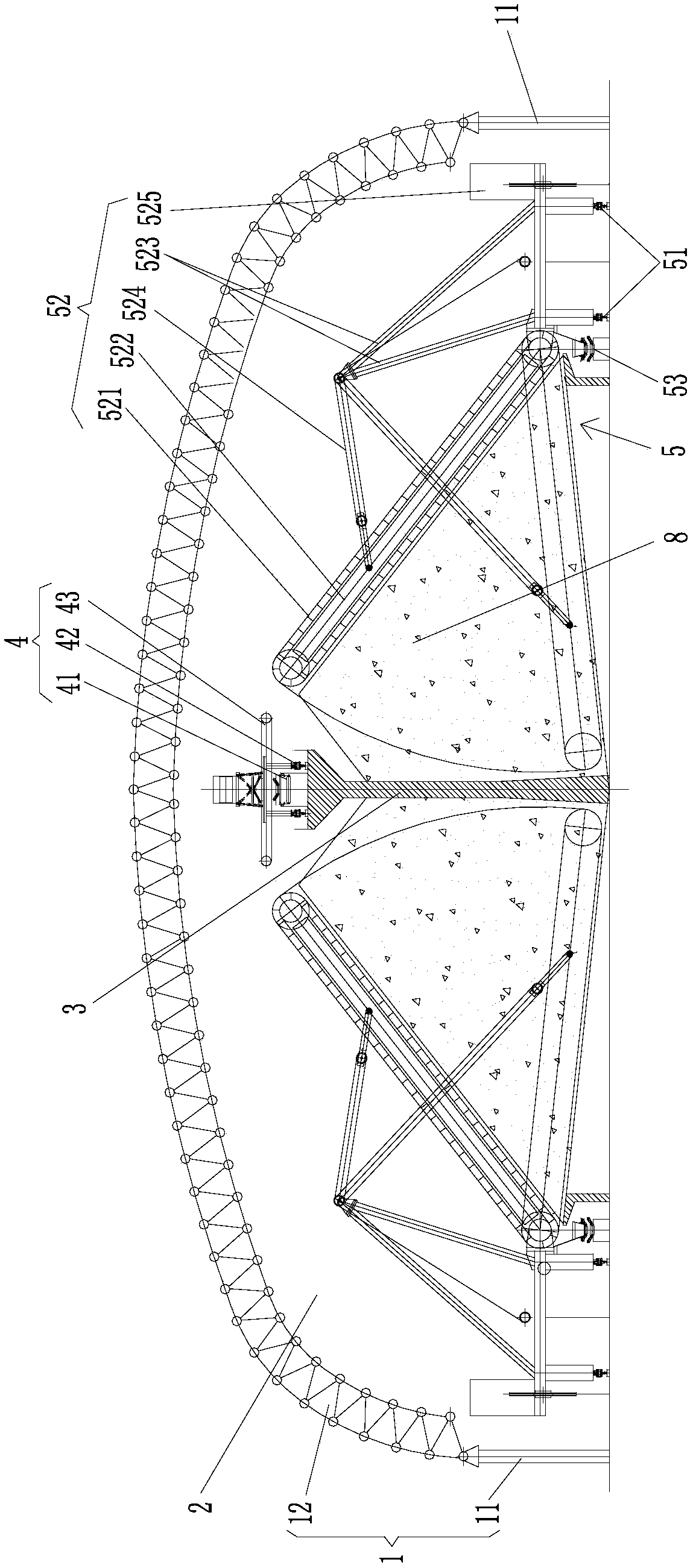

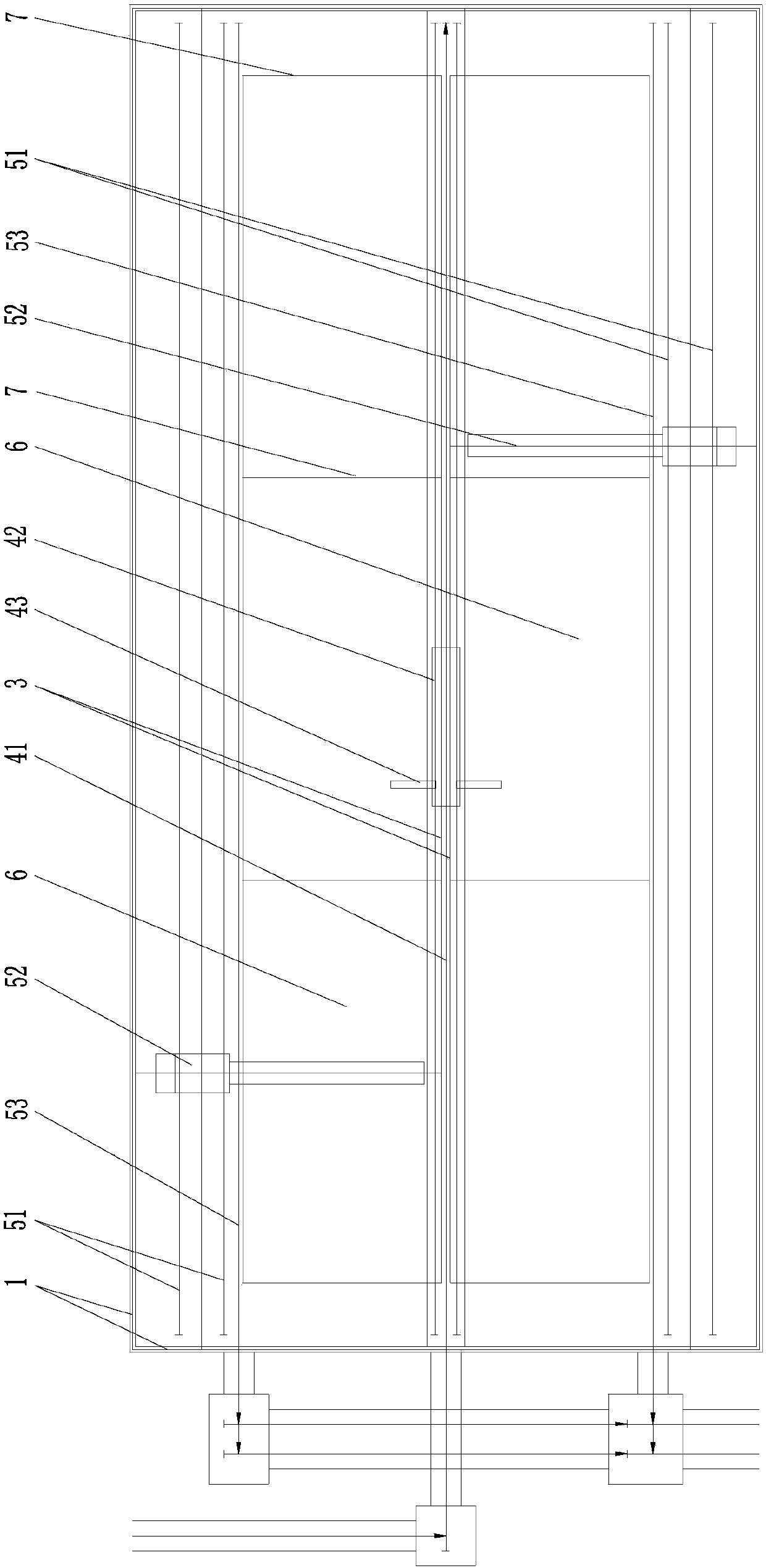

[0029] Such as figure 1 , figure 2 As shown, the present invention provides a kind of closed storage storehouse, and it has closed storehouse shell 1 (or be referred to as storehouse outer body), and closed storehouse is a single-span storehouse or is made up of a plurality of single-span storehouses. A multi-span material warehouse composed of connections, each single-span material warehouse includes a stockyard 2 located in the shell of the warehouse 1, a retaining wall 3 (or called an intermediate retaining wall) located in the stockyard 2, and a material input system 4 And the material output system 5, that is, the retaining wall 3, the material input system 4 and the material output system 5 are all located in the stockyar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com