Hydraulic locking rotary joint

A slewing joint, hydraulic technology, applied in fluid pressure actuating devices, medical science, manipulators, etc., can solve the problem that the size and weight are difficult to meet the design indicators, and achieve the effect of convenient control, large slewing torque, and reliable bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

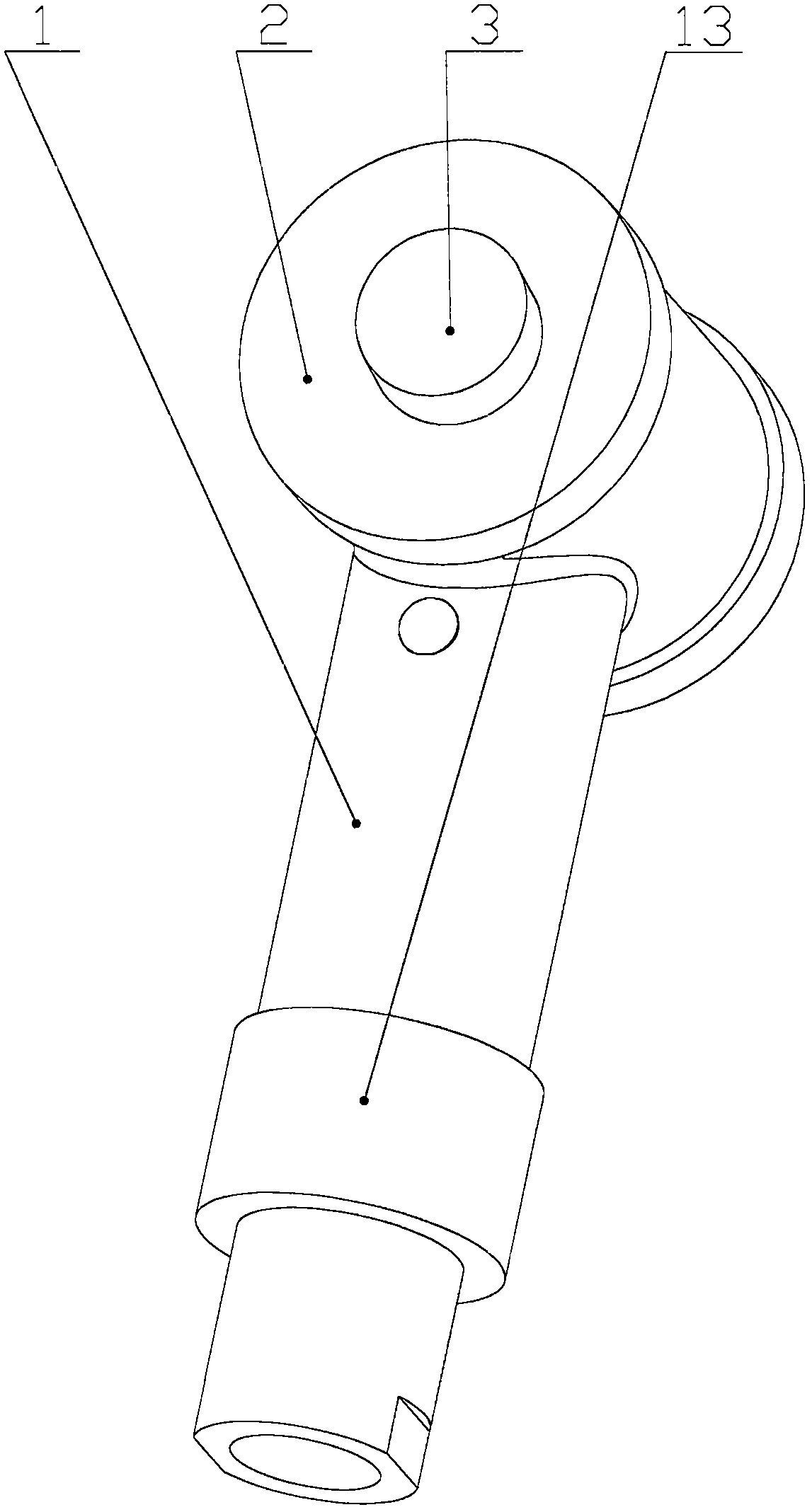

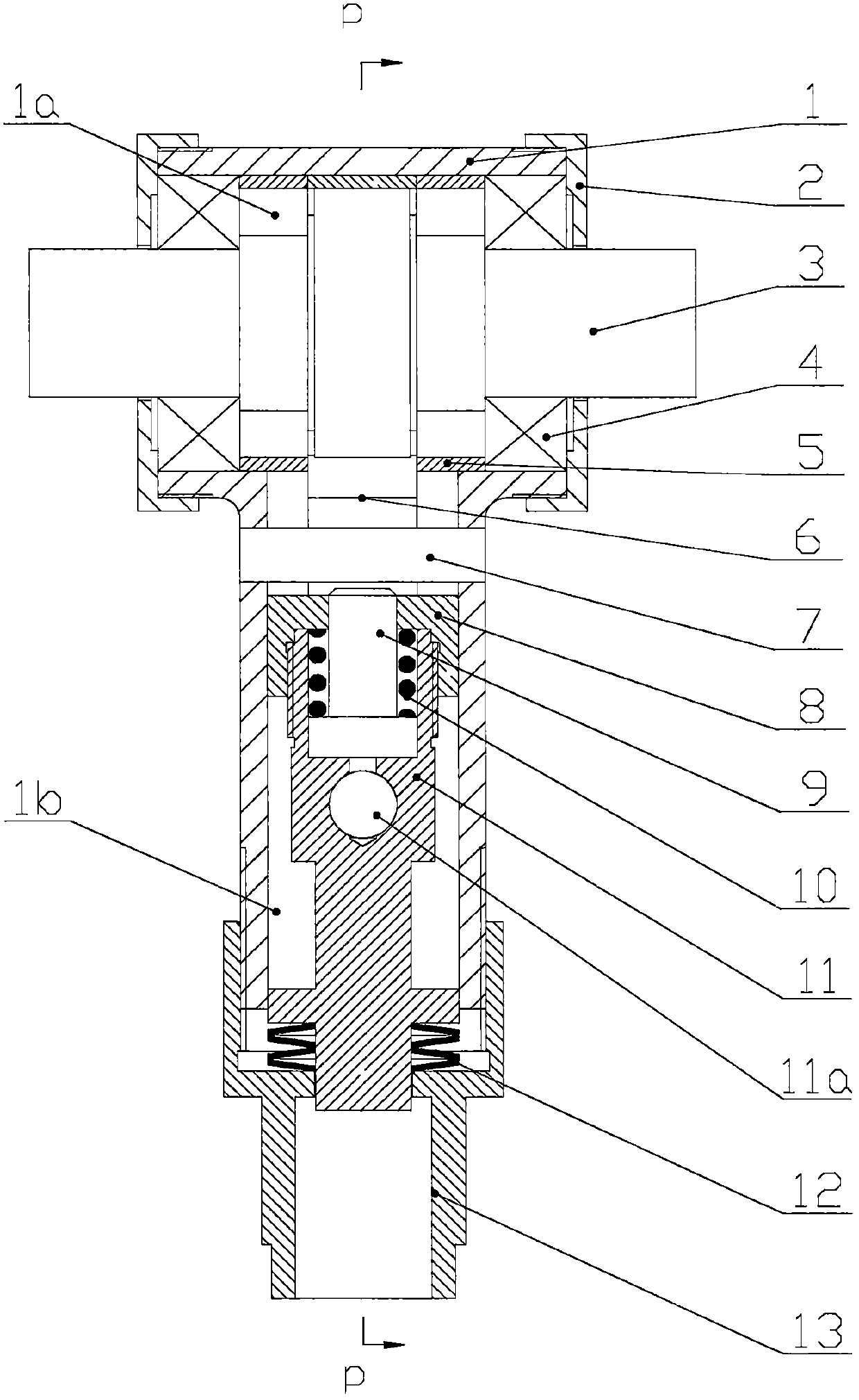

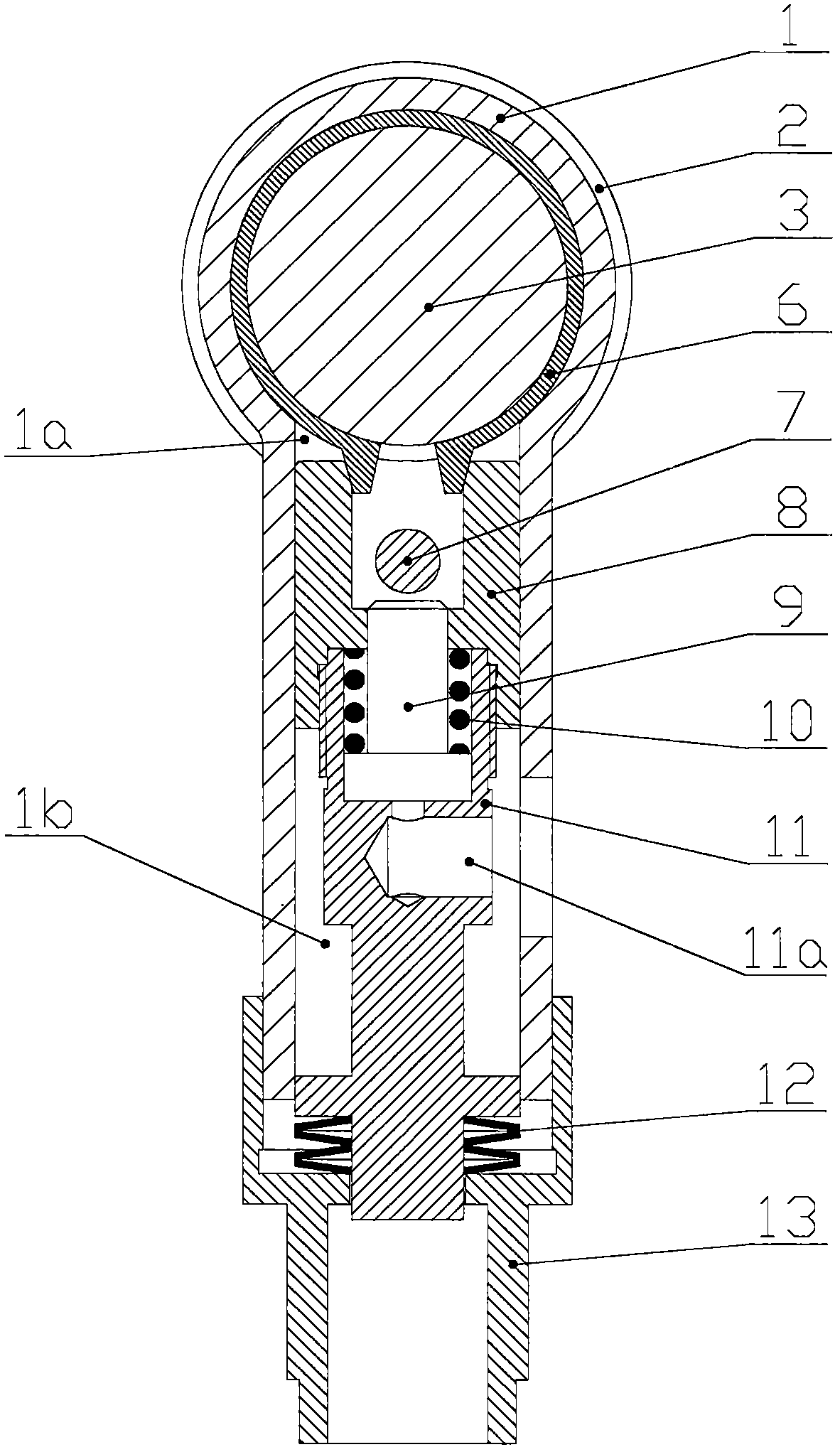

[0019] As shown in the accompanying drawings, the hydraulic locking rotary joint is mainly composed of a housing 1, a mandrel 3, a braking member 6, an oil cylinder barrel 11, an oil cylinder cover 8, a piston rod 9, a return spring 10, and a disc spring group 12. Its specific structure is that there are channel A 1a and channel B 1b in the shell 1, and the two channels intersect and pass through. A mandrel 3 is supported by a bearing 4 in the channel A 1a, and a brake 6 is installed outside the mandrel 3; 1b is close to the front of channel A 1a, and there is a radial stop pin 7 with both ends fixed on the casing 1, and a gland 13 is installed at the rear of channel B 1b; oil cylinder barrel 11 and oil cylinder cover 8 are also installed in channel B 1b , piston rod 9, return spring 10 composed of a hydraulic cylinder, the boss at the front end of the cylinder cover 8 is in contact with the brake piece 6, the front end of the piston rod 9 is in contact with the stop pin 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com