Turning center clamp of irregular eccentric valve deck

A turning center, eccentric valve technology, applied in clamping, clamping devices, manufacturing tools, etc., can solve problems such as low efficiency, negative impact on parts machining accuracy, and long processing time for a single piece, achieving low technical level requirements, easy to use Clamping and disassembly to ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

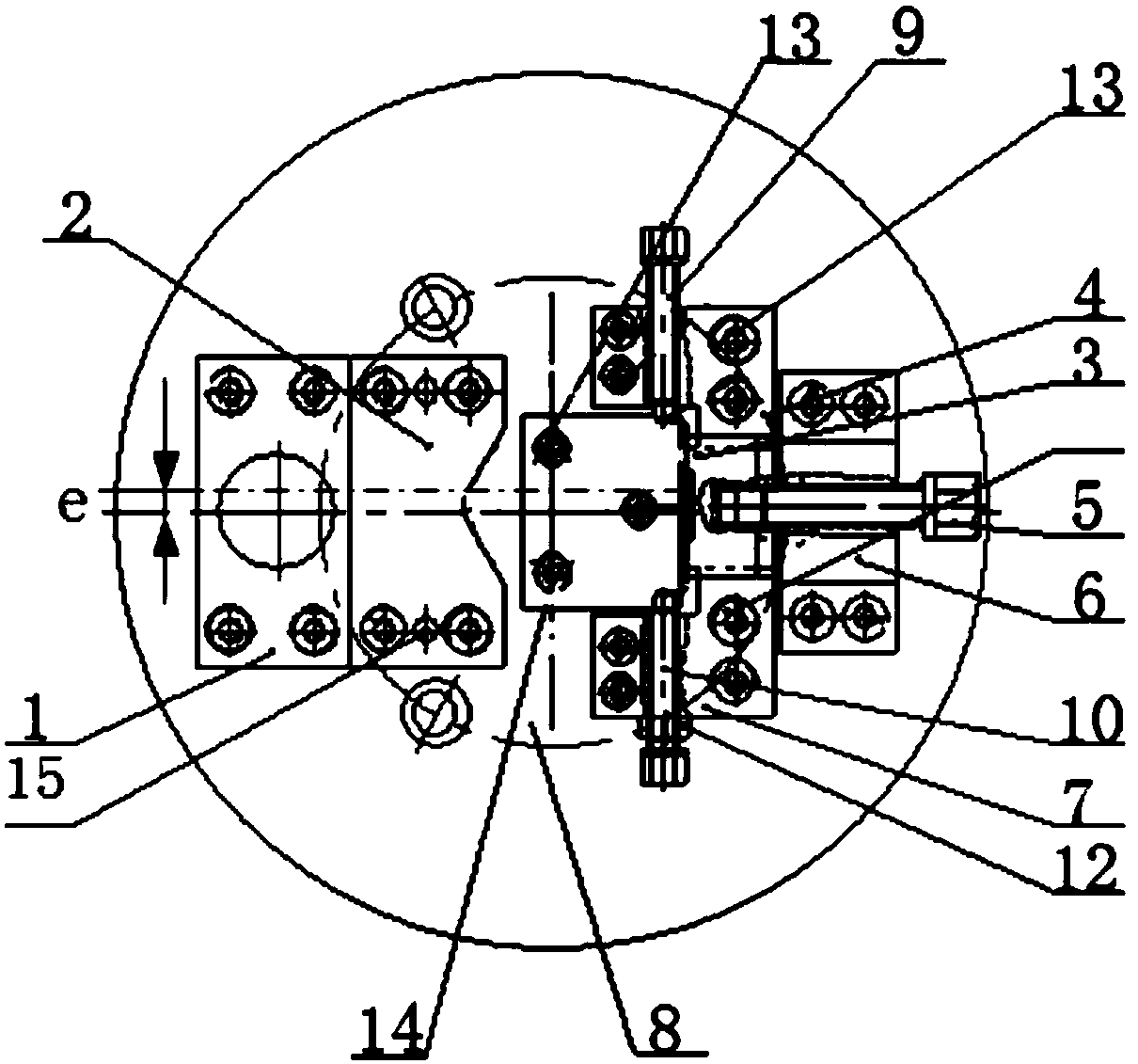

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

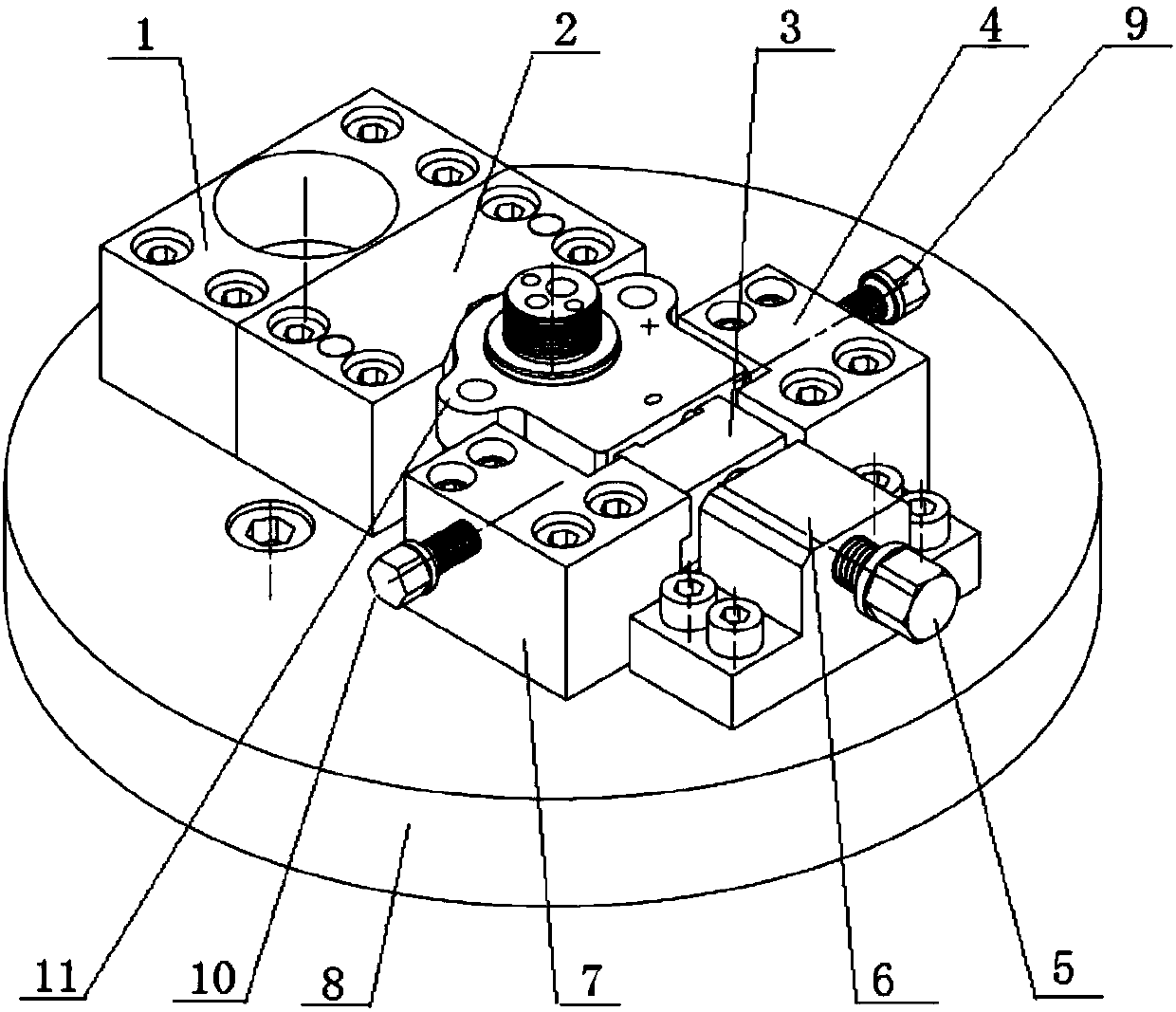

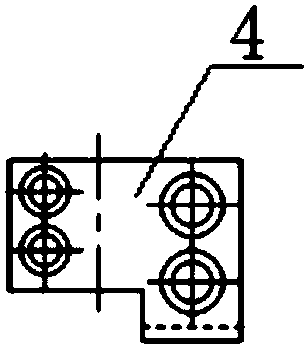

[0027] Such as figure 1 and figure 2 As shown, a turning center fixture for an irregular eccentric bonnet according to the present invention includes a flange 8 and a positioning mechanism installed on the flange 8, a clamping mechanism and a counterweight 1, and the positioning mechanism Including V-shaped positioning block 2, positioning bottom plate 14, upper limit block 4, lower limit block 7, movable screw 9 and first compression screw 10, the clamping mechanism includes movable pressure block 3, second compression screw 5 and Press seat 6. In this embodiment, there is an eccentricity of 1.75 mm between the outer circle to be processed on the valve cover part 11 and the center of the surface of the valve cover part 11 .

[0028] The positioning bottom plate 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com