Hole-turning device for part with two parallel holes

A parallel hole and part technology, which is applied in the field of two parallel hole parts turning device, achieves the effect of simple fixture structure and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

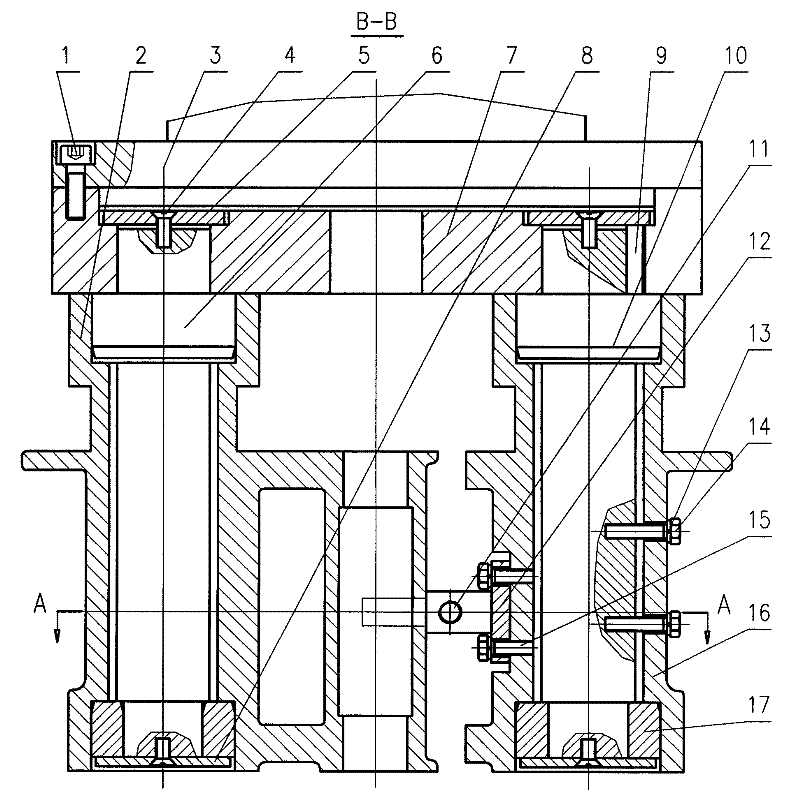

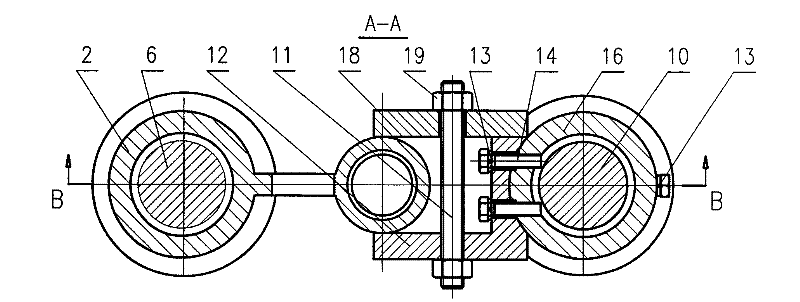

[0012] The attached picture is an important part of the LM24-2C rice huller, the two-parallel-hole part-turning device of the slow roller moving shell seat. The slow roller moving housing has two sets of holes parallel to each other. One group of holes is the hole that slow roller shaft is installed, and the endoporus of its front and rear end all is the bearing installation hole of diameter 62 millimeters, and the middle is the hole of diameter 47 millimeters. The two ends of another group of holes are the holes of diameter 28 millimeters, and the center is the hole of diameter 32, and this group of holes is processed with this two parallel hole part turning device on lathe.

[0013] The fixture disc (7) is fixed on the flange (3) of the lathe through its large inner hole and fixed with the hexagon socket head cap screw (1), and the part mandrel (6) of the installation part (2) is installed on the cylinder through its rear end. In the corresponding hole of the fixture plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com