Gear milling clamp for bevel gear

A bevel gear and tooth milling technology, which is applied to gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of complex structure and high manufacturing cost of bevel gear fixtures, and achieve convenient and fast clamping and low manufacturing cost , The effect of simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

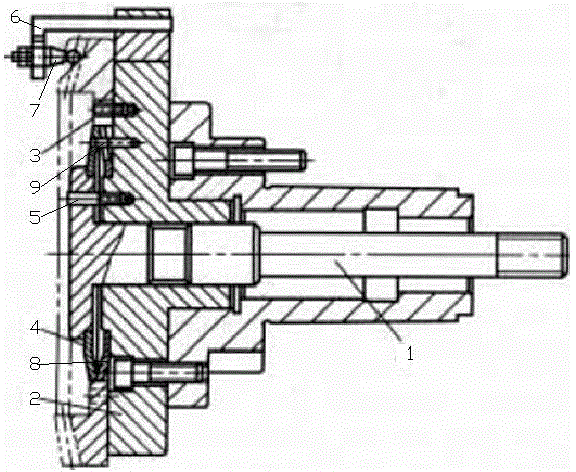

[0014] As shown in the figure, the bevel gear milling fixture of this embodiment includes a pull rod 1 and a positioning plate 2 that is coaxially sleeved on the pull rod. The positioning plate and the pull rod slide in the axial direction. There is a chamfered positioning pin 3, and a centering shaft section is integrally provided on the other end surface of the positioning plate;

[0015] The end of the pull rod is integrally provided with a pressure plate, and the end of the pressure plate close to the positioning plate is provided with an annular step, and the first disc spring 4 is sleeved on the annular step;

[0016] It also includes a first circumferential positioning pin 5 arranged on the positioning plate and slidingly fitted with the pressure plate in the axial direction.

[0017] The bevel gear milling jig of this embodiment locates the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com