Tool for machining multiple guider blades of large gas turbine

A guider and vane technology, which is applied in the field of large-scale gas turbine multi-connector guider vane processing tooling, can solve the problems such as difficult to guarantee the quality of blade processing, and achieve the effect of improving positioning stability, avoiding being crushed, and realizing installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

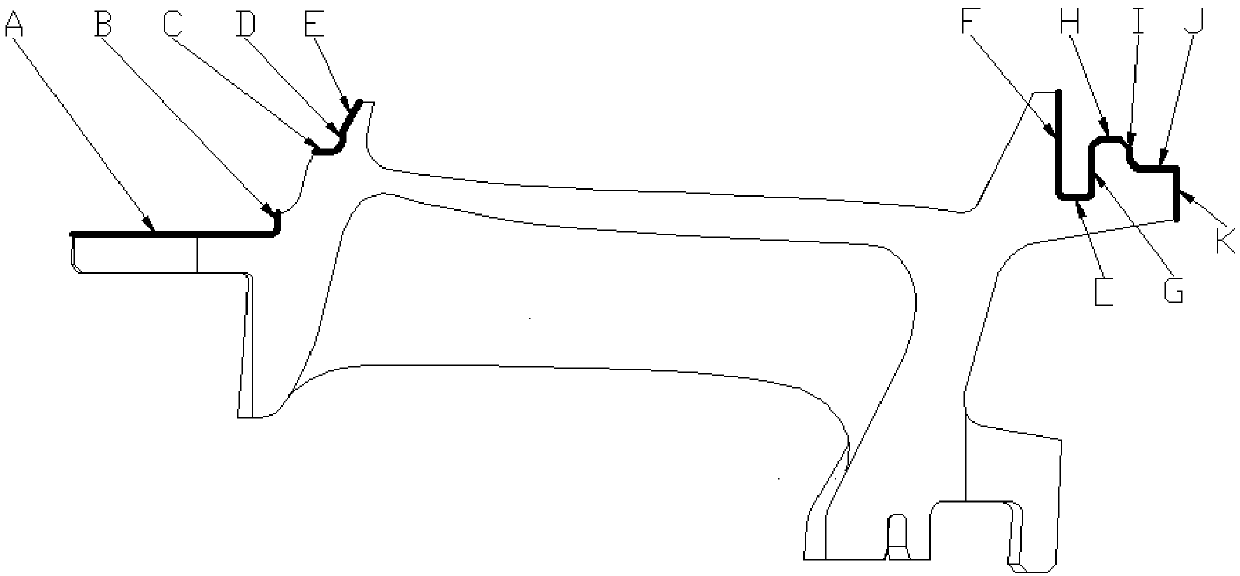

[0031] The large-scale gas turbine multi-connector guide vanes targeted by this embodiment are as follows: figure 1 and Figure 7 As shown, the multi-steering guide blade of the large gas turbine is mainly composed of the blade body and the large and small edge plates located on both sides of the blade body. There are 12 parts from A to L on the blade to be processed.

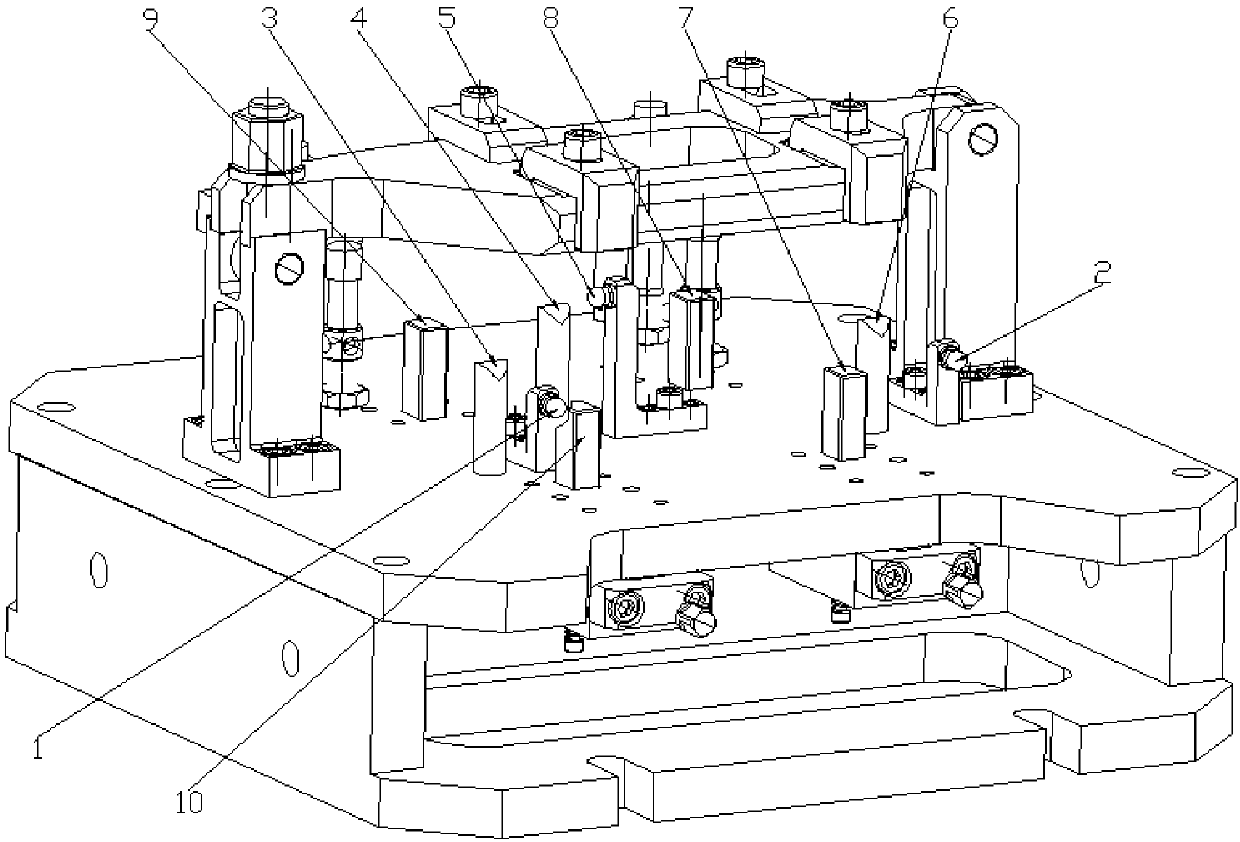

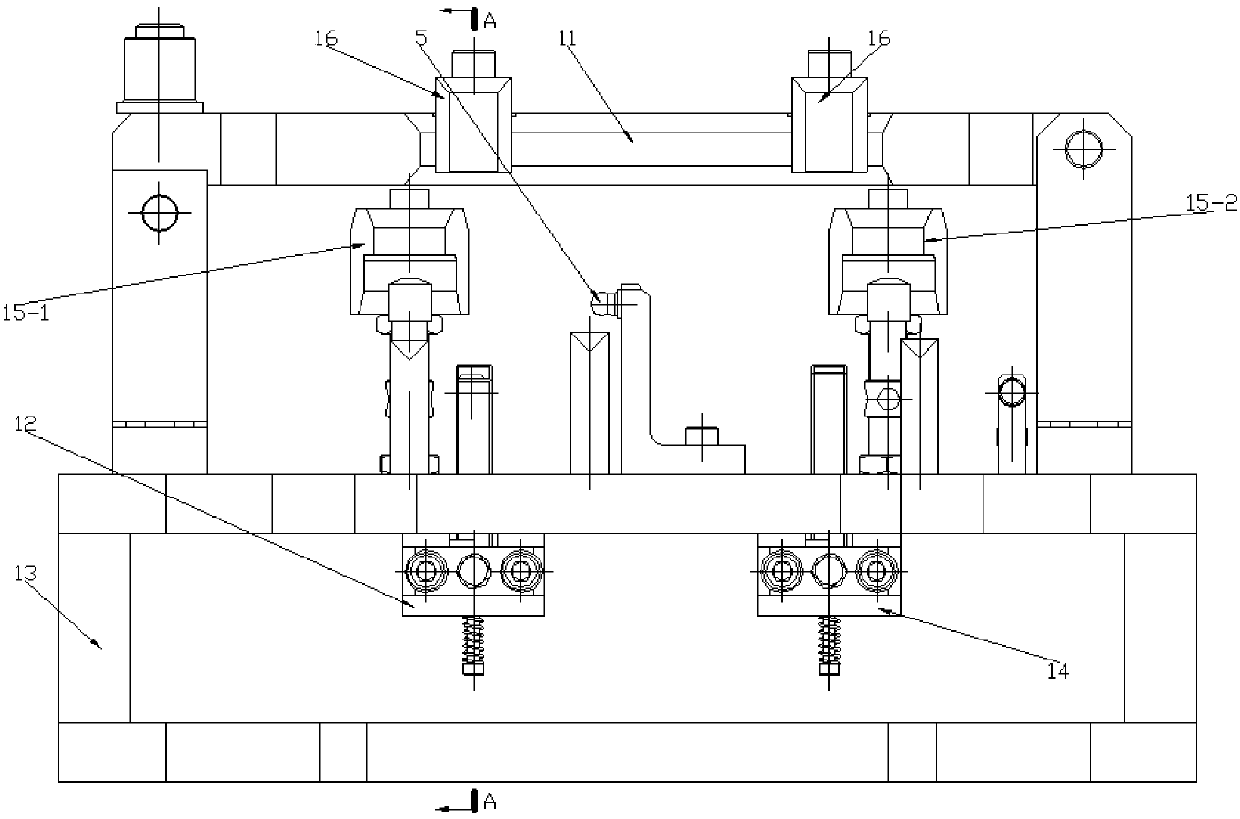

[0032] The tooling provided in this embodiment for processing multiple guide vanes of large gas turbines, such as 2 to Figure 5 , Figure 8 As shown, it includes a tooling seat 13 and a positioning support mechanism and a pressing mechanism arranged on the upper seat plate of the tooling seat. The positioning support mechanism includes a fixed positioning support mechanism and an auxiliary positioning support mechanism; the pressing mechanism includes a blade body pressing mechanism and a small end edge plate auxiliary pressing mechanism.

[0033] Such as image 3 The shown tooling seat 13 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com