Self-adaptive inverse tracking control method for super-magnetostrictive tracking platform

A giant magnetostrictive and tracking platform technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of non-existence of transfer function, inability to be directly applied, inability to apply nonlinear system control, etc., to achieve Improve tracking control accuracy, improve accuracy and stability, and control direct effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

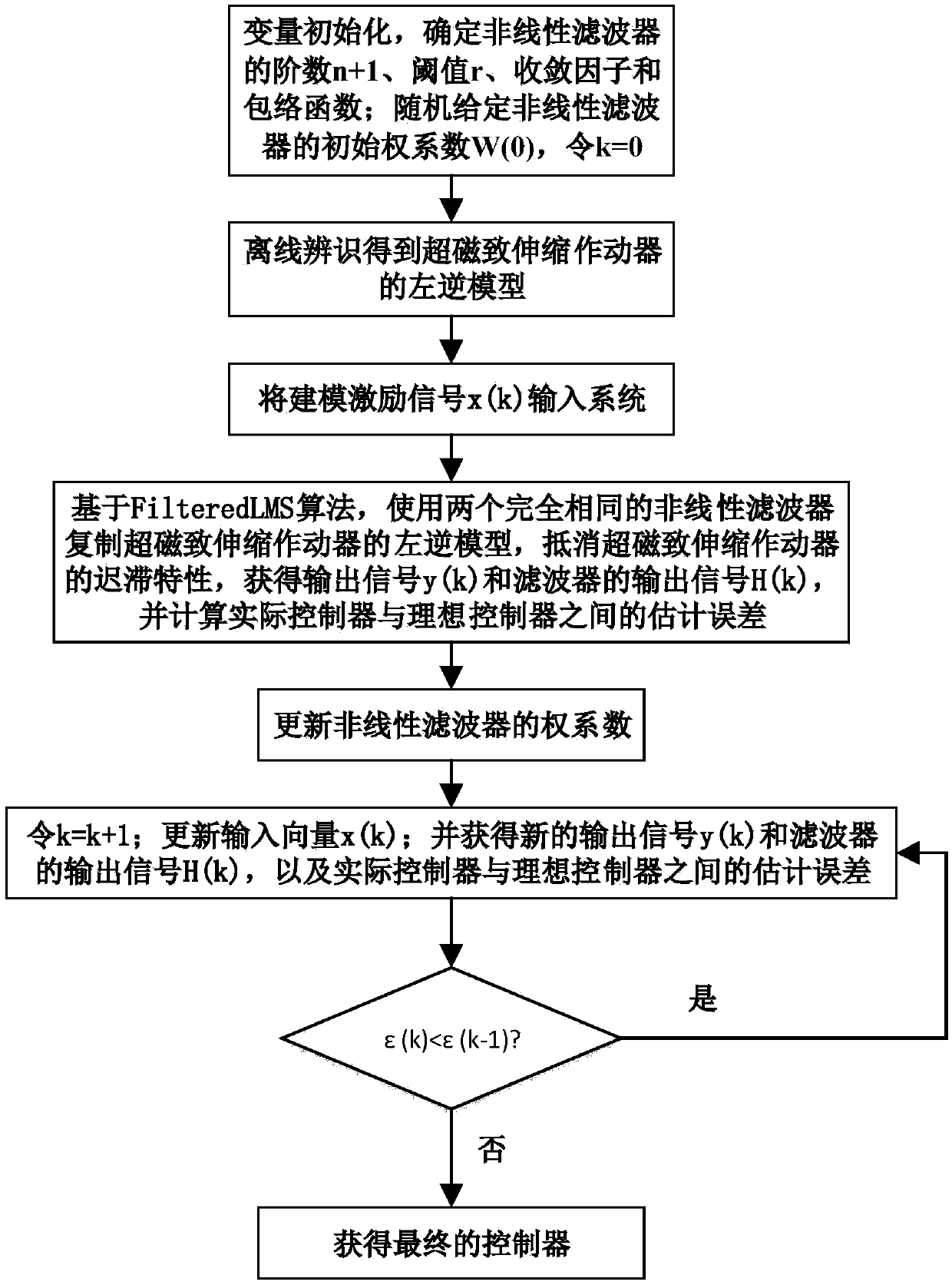

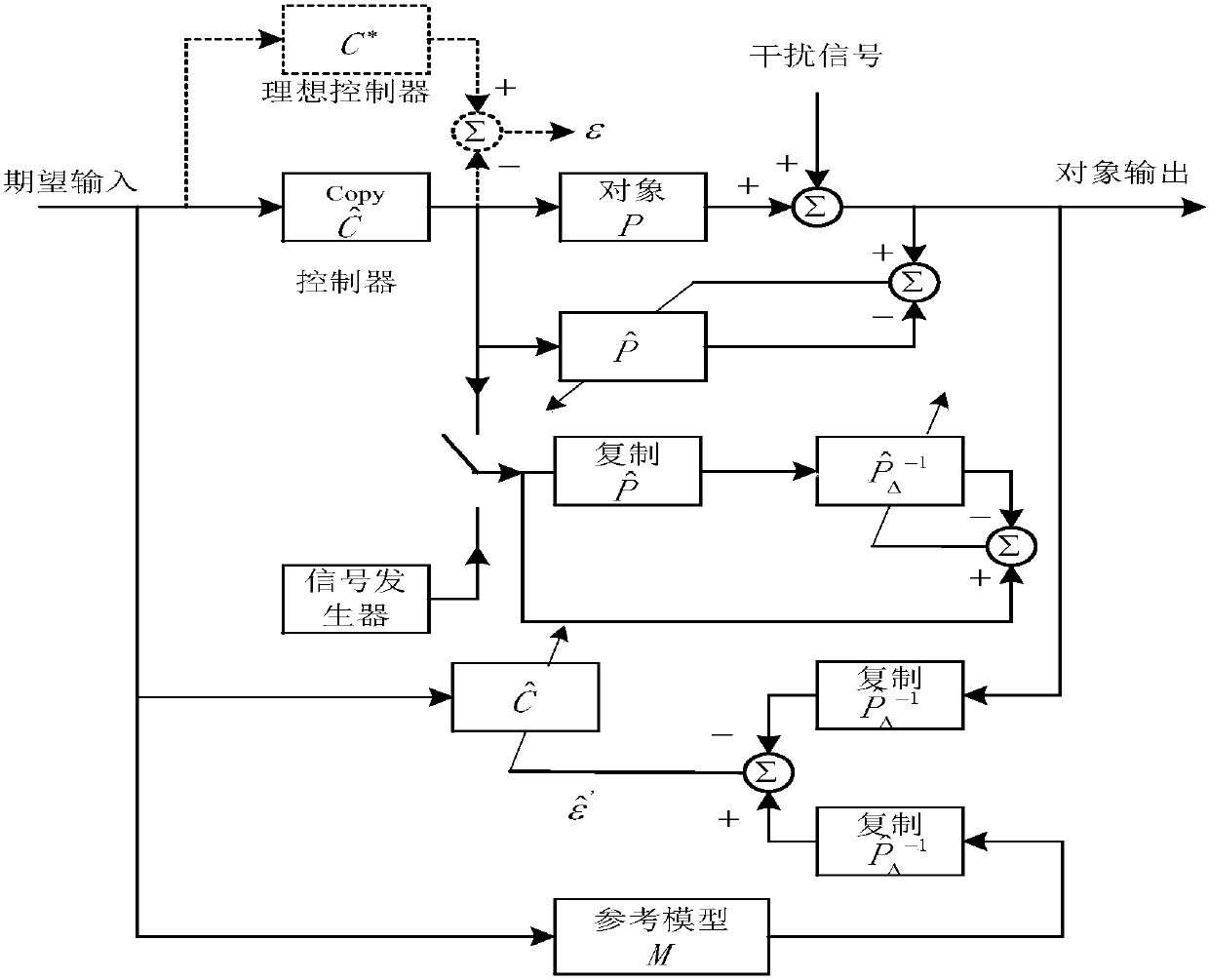

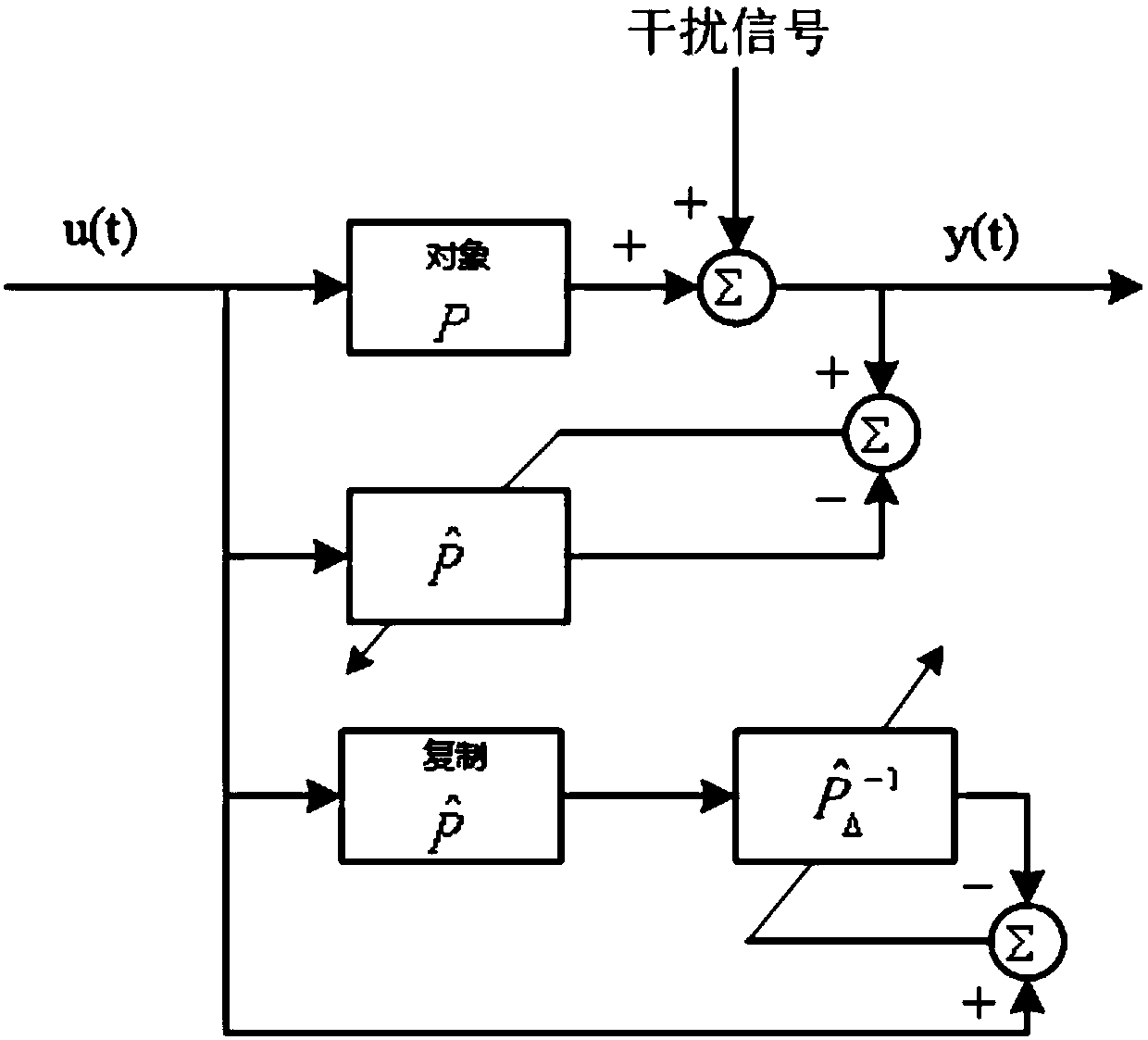

[0043] Embodiment 1 of the present invention: a kind of adaptive inverse tracking control method for giant magnetostrictive tracking platform, such as figure 1 As shown, the following steps are included: First, the left inverse model of the giant magnetostrictive actuator is obtained through offline identification; secondly, based on the Filtered-ε LMS algorithm, two identical nonlinear filters are used to replicate the giant magnetostrictive actuator The left inverse model of the device; finally, use the error signal obtained by subtracting the output of the two nonlinear filters to adaptively find the controller C, and use the LMS algorithm to adjust the weight coefficient of the filter on-line until the giant magnetostriction The output of the actuator is the same as the output of the reference model; wherein, the two identical nonlinear filters, wherein the input of one nonlinear filter is the object output; the input of the other nonlinear filter is the reference model ou...

Embodiment 2

[0056] Embodiment 2: a kind of adaptive inverse tracking control method for giant magnetostrictive tracking platform, such as figure 1 As shown, the following steps are included: first, the left inverse model of the giant magnetostrictive actuator is obtained through offline identification; secondly, based on the Filtered-εLMS algorithm, two identical nonlinear filters are used to replicate the giant magnetostrictive actuator The left inverse model of the left inverse model; finally, use the error signal obtained by subtracting the output of the two nonlinear filters to adaptively find the controller C, and use the LMS algorithm to adjust the weight coefficient of the filter online until the giant magnetostrictive action The output of the filter is the same as the output of the reference model; wherein, the two identical nonlinear filters, wherein the input of one nonlinear filter is the object output; the input of the other nonlinear filter is the output of the reference model...

Embodiment 3

[0058] Embodiment 3: a kind of adaptive inverse tracking control method for giant magnetostrictive tracking platform, such as figure 1 As shown, the following steps are included: first, the left inverse model of the giant magnetostrictive actuator is obtained through offline identification; secondly, based on the Filtered-εLMS algorithm, two identical nonlinear filters are used to replicate the giant magnetostrictive actuator The left inverse model of the left inverse model; finally, use the error signal obtained by subtracting the output of the two nonlinear filters to adaptively find the controller C, and use the LMS algorithm to adjust the weight coefficient of the filter online until the giant magnetostrictive action The output of the filter is the same as the output of the reference model; wherein, the two identical nonlinear filters, wherein the input of one nonlinear filter is the object output; the input of the other nonlinear filter is the output of the reference model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com