High thrust vector vertical type test device structure

A testing device and high-thrust technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of low natural frequency and small test range, and achieve high precision, simple installation and debugging, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

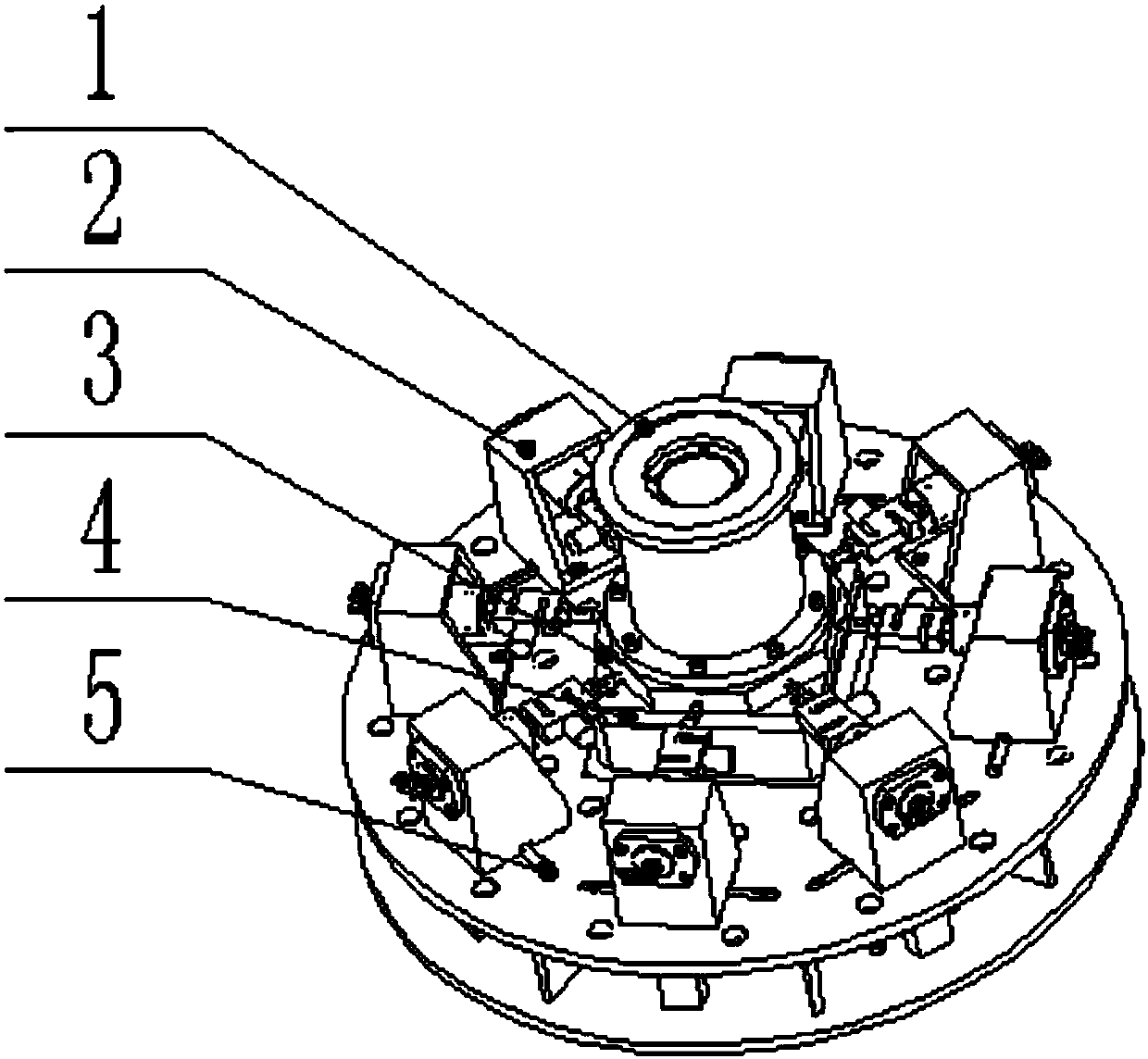

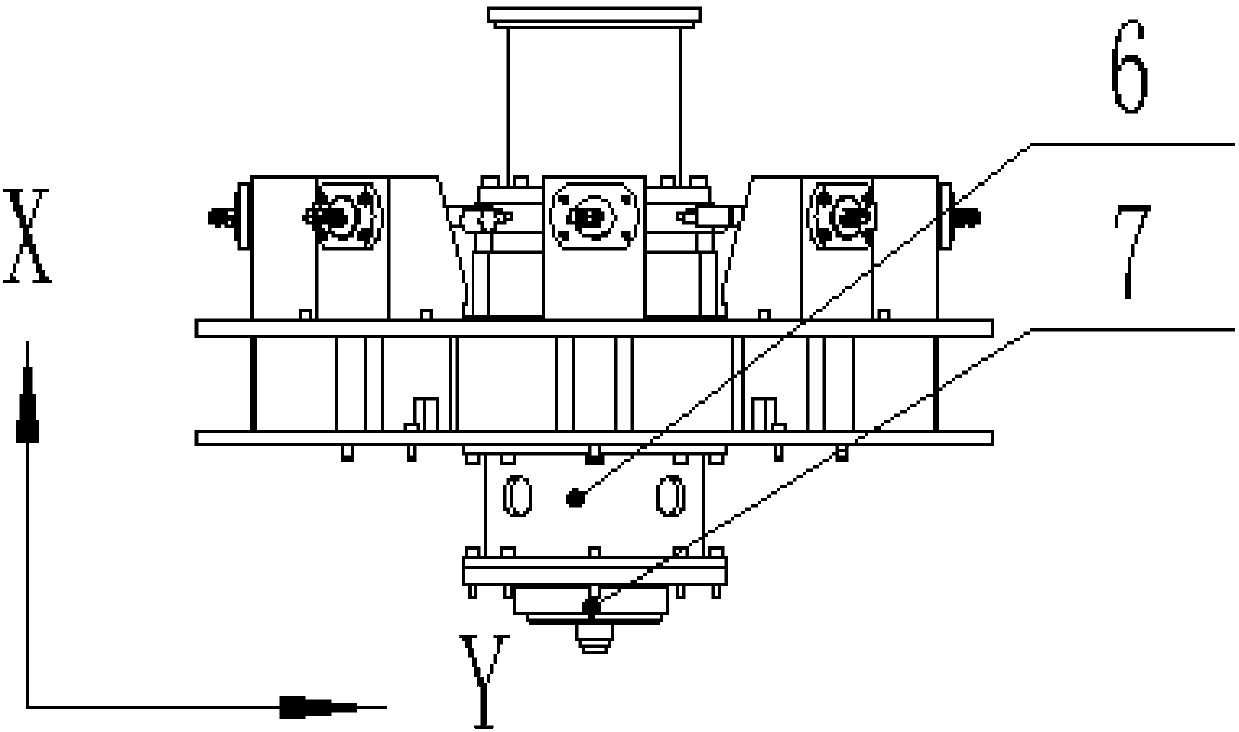

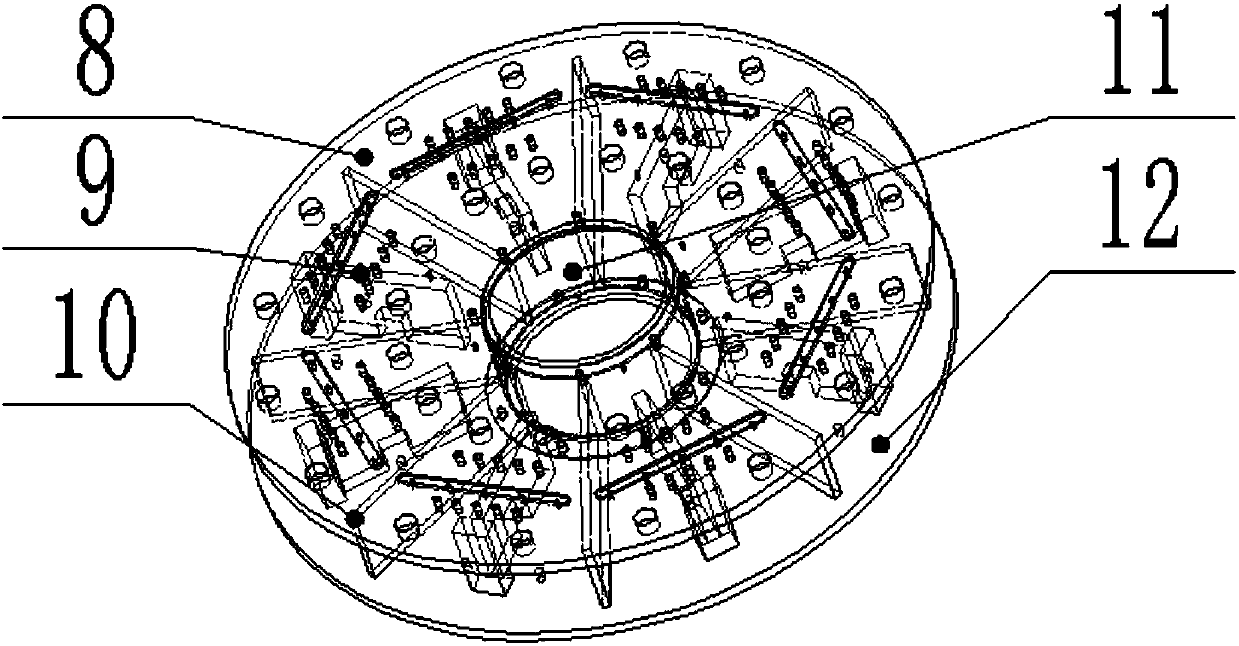

[0024] After the main direction hydraulic power system 7 is connected to the hydraulic oil, it provides power for the calibration of the main direction, and realizes the simulated loading of the main direction force in the X direction; the lateral force is obtained by laterally loading the hydraulic oil Device 2 applies force to the sides of the calibration plate to respectively realize simulated loading in the Y and Z directions. Five sets of threaded holes with the same spacing and the same size are arranged on each station of the upper plate 8 of the support round table, and the side loading device 2 can slide along the key to finally realize the transformation of the three stations. When the two opposite side loading devices 2 are in the two opposite limit positions respectively, the torque M can be rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com