High-speed S module multi-return-stroke heat exchanger

A multi-return, heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., to achieve the effects of prolonging service life, saving construction investment, and increasing stroke length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the drawings and examples, but the present invention is not limited to the following embodiments.

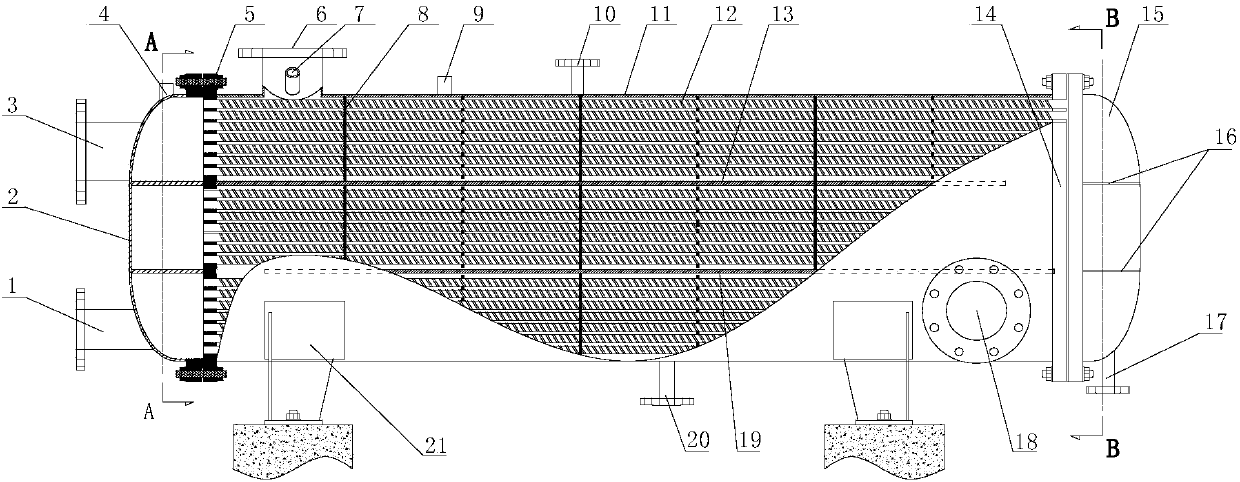

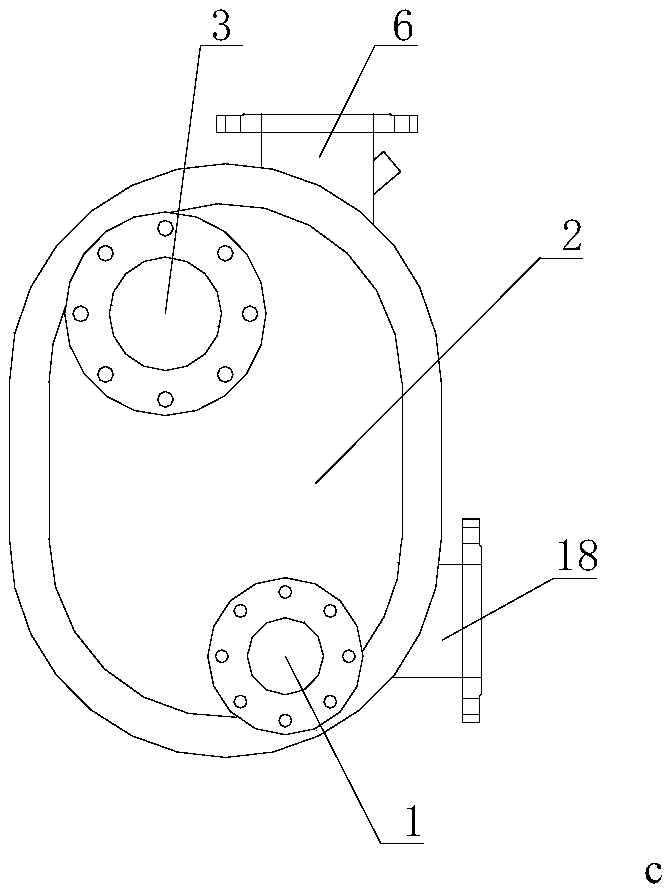

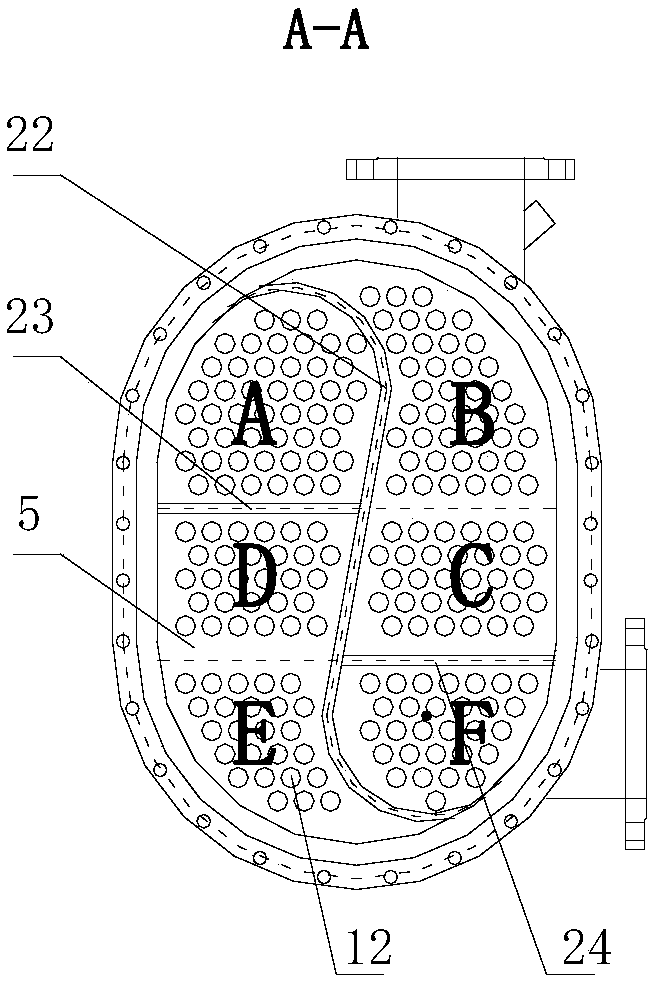

[0025] exist Figure 1~4 Among them, the high-speed S-module multi-return heat exchanger of the present invention consists of a heat source outlet flange 1, a first head 2, a heat source inlet flange 3, a tube side pressure gauge interface 4, a first tube plate 5, and a cold source outlet flange 6. Thermometer interface 7, baffle plate 8, shell side pressure gauge interface 9, safety valve interface 10, shell 11, heat exchange tube 12, second deflector plate 13, second tube plate 14, second head 15 , the fourth head partition 16, the pipe-side blowdown valve interface 17, the cold source inlet flange 18, the first deflector 19, the shell-side blowdown valve interface 20, the mounting support 21, the first head partition 22, The second head partition 23 and the third head partition 24 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com