Offline filtration system for high-precision wind power gear box

A wind power gearbox and filter system technology, applied in wind power generation, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem of filter structure blockage, achieve high safety, comprehensive and efficient filter effect, and high filter efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

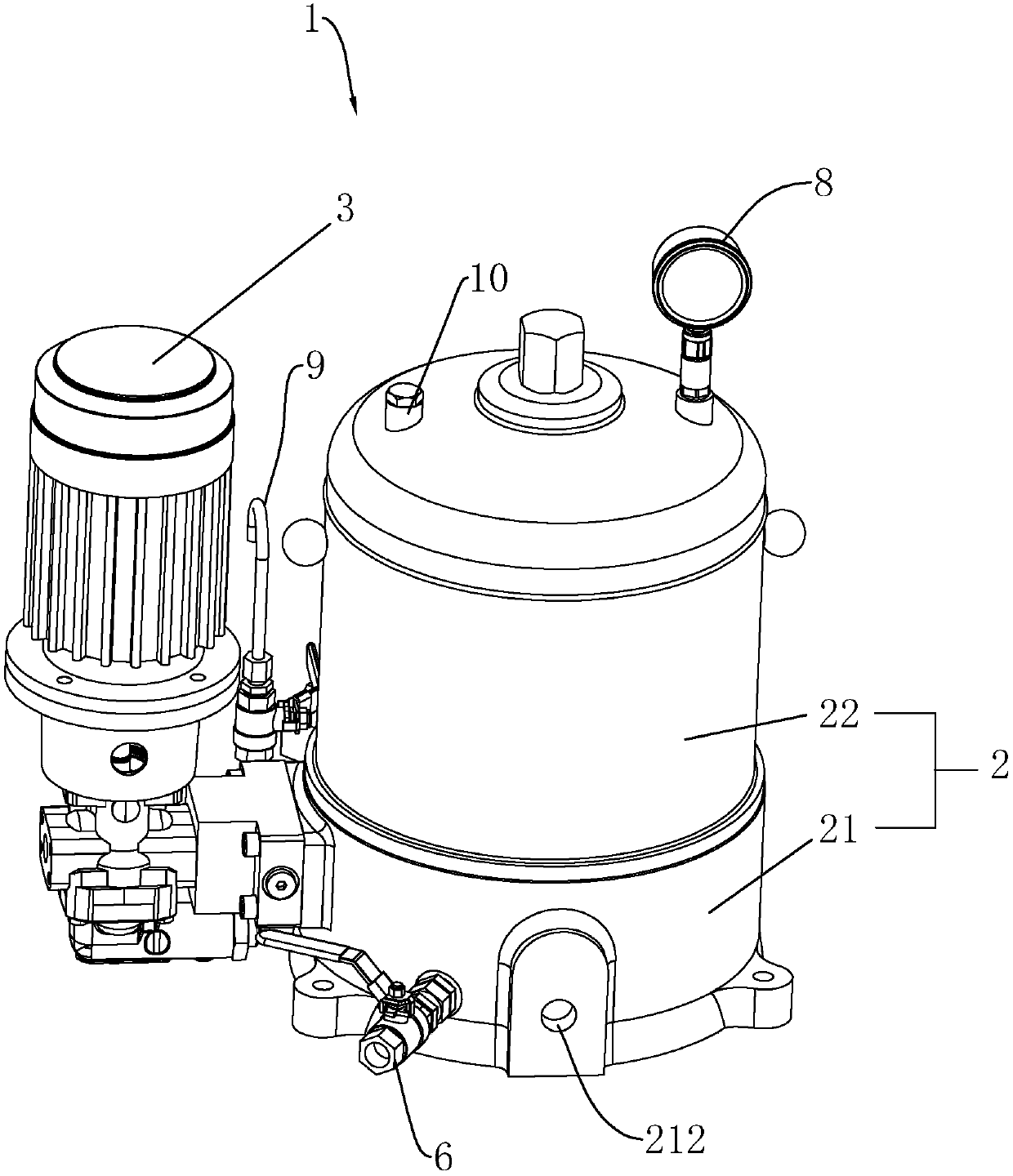

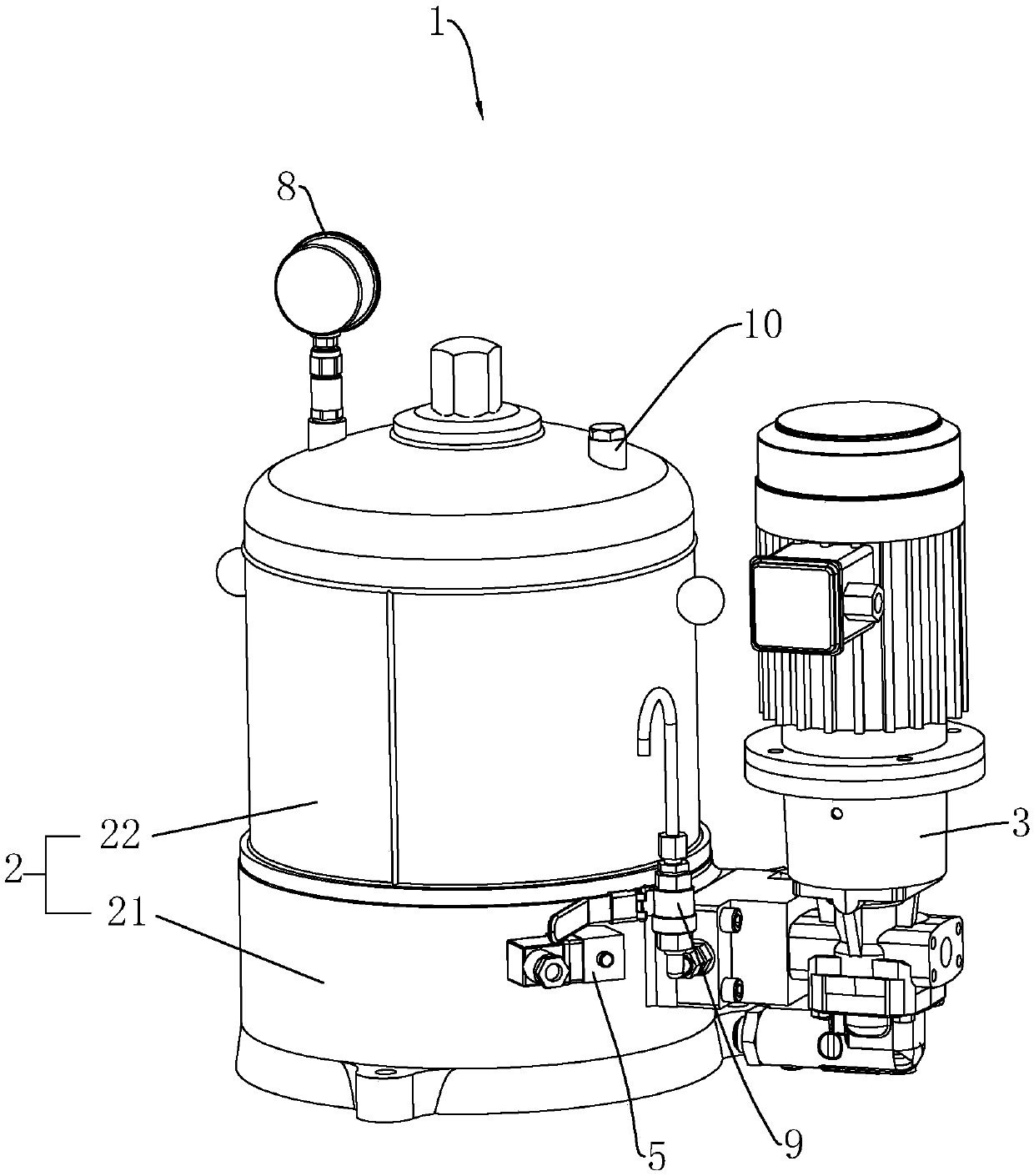

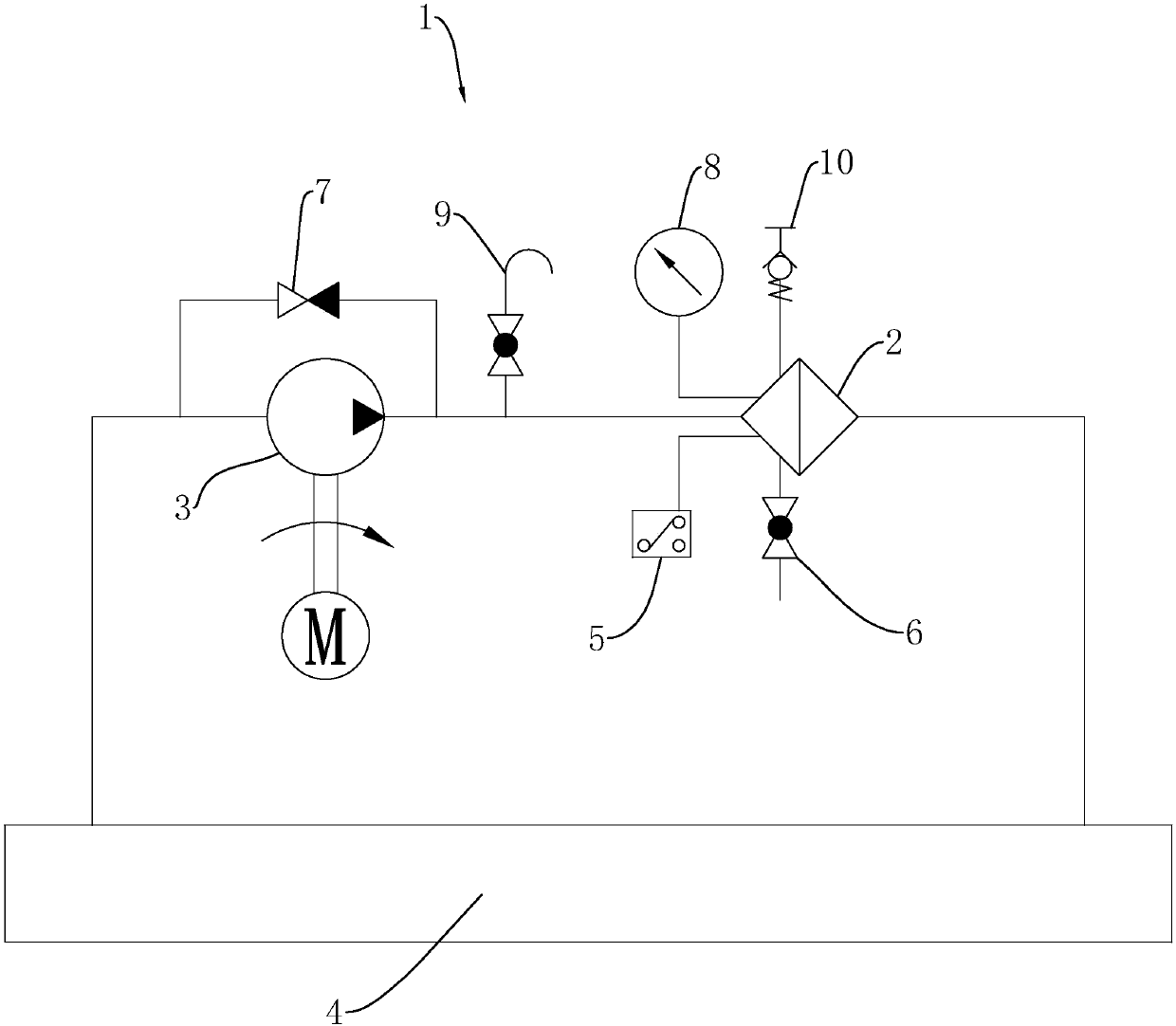

[0044] Example: Reference figure 1 , an off-line filter system for a high-precision wind power gearbox, including a filter device 1, the filter device 1 includes a filter assembly 2 and a motor pump assembly 3 connected to the filter assembly 2, the motor pump assembly 3 pumps oil and enters the oil into the filter assembly 2. The filter assembly 2 returns the filtered oil to the gearbox 4 ( image 3 shown in ).

[0045] combine image 3The schematic diagram of the structure, the gear box 4 is connected to the motor pump assembly 3 and the filter assembly 2, the motor pump assembly 3 is connected to a bypass safety valve 7, and the bypass safety valve 7 can discharge the oil when the pressure inside the filter assembly 2 exceeds 2.8bar The fluid returns to the gear box 4; a sampling valve 9 is connected between the filter assembly 2 and the motor pump assembly 3 for taking oil samples; the filter assembly 2 is connected with a pressure gauge 8, an exhaust valve 10, a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com