High-speed gearbox thrust disc structure

A thrust plate and gear box technology, applied in belts/chains/gears, rotating parts against centrifugal force, sliding contact bearings, etc., can solve problems such as difficulty in fine-tuning the thrust surface, failure of the thrust plate structure, and poor dynamic stability, etc. To achieve the effect of convenient disassembly of the structure, stable rotation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

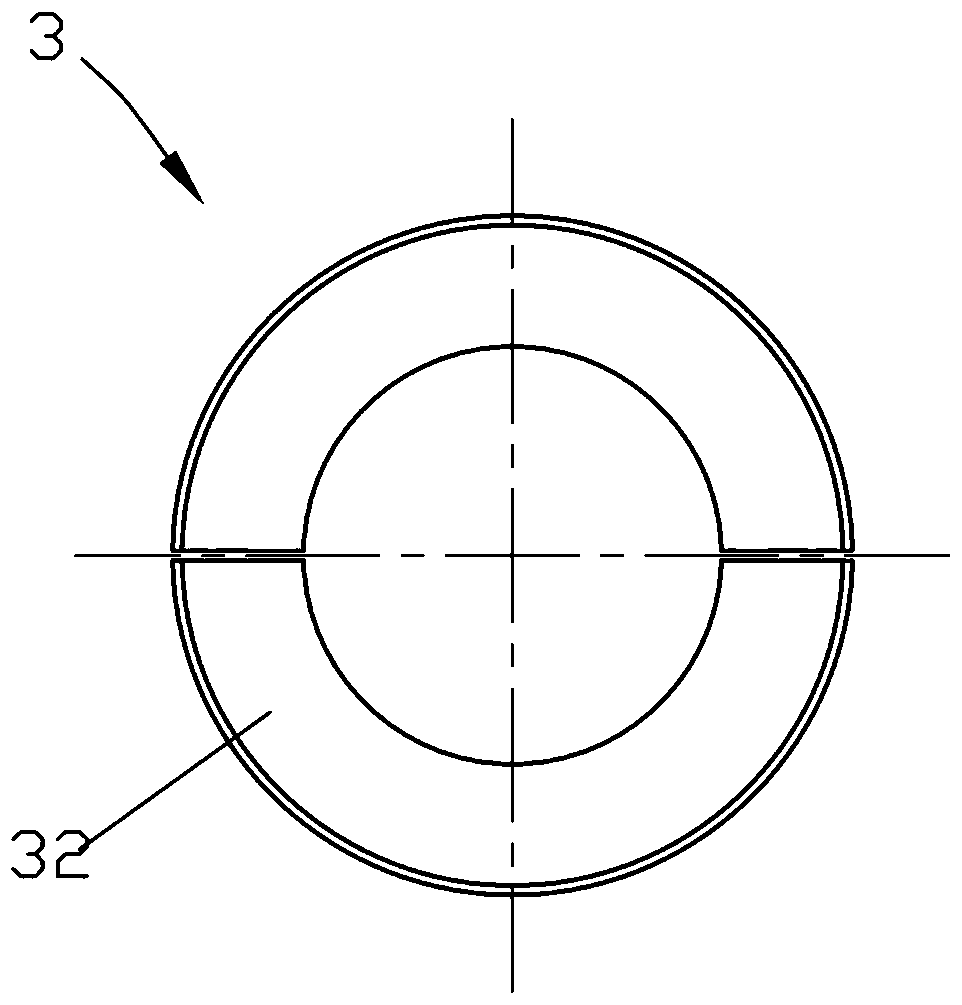

[0030] like Figure 1-Figure 2 As shown, the embodiment of the present invention discloses a thrust plate structure of a high-speed gearbox, including a high-speed gear shaft 1 and a driving gear 2. Shaft shoulder 12, an annular clamping groove 13 is formed between the gear portion 11 and the shaft shoulder 12, and the retaining ring 3 is set inside the annular clamping groove 13, wherein the retaining ring 3 is composed of two semi-circular rings 32, which are Firstly process it into a ring as a whole, and then use wire cutting to separate and form two semi-circular rings 32. Any retaining ring 3 is fitted with a thrust disc 4, and the thrust disc 4 and the retaining ring 3 are an interference fit. The thrust surface 5 is formed by contacting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com