Gap adjusting device for main rail and guard rail

A gap adjustment device and technology for gap adjustment, applied to tracks, rails, track superstructures, etc., can solve problems such as derailment of low-floor vehicles, and achieve the effects of avoiding derailment accidents, good stability and safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

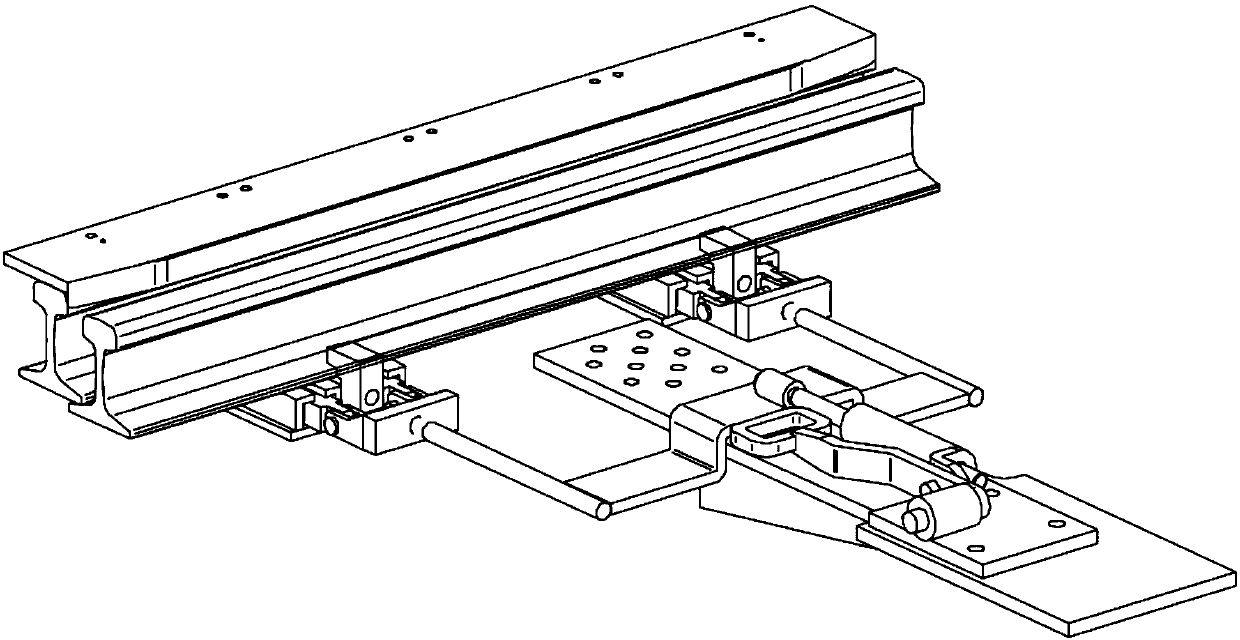

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

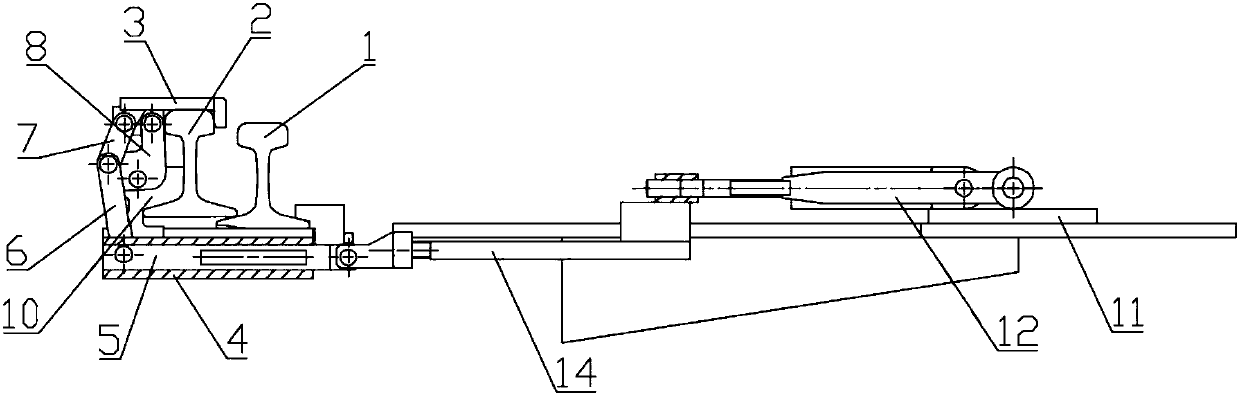

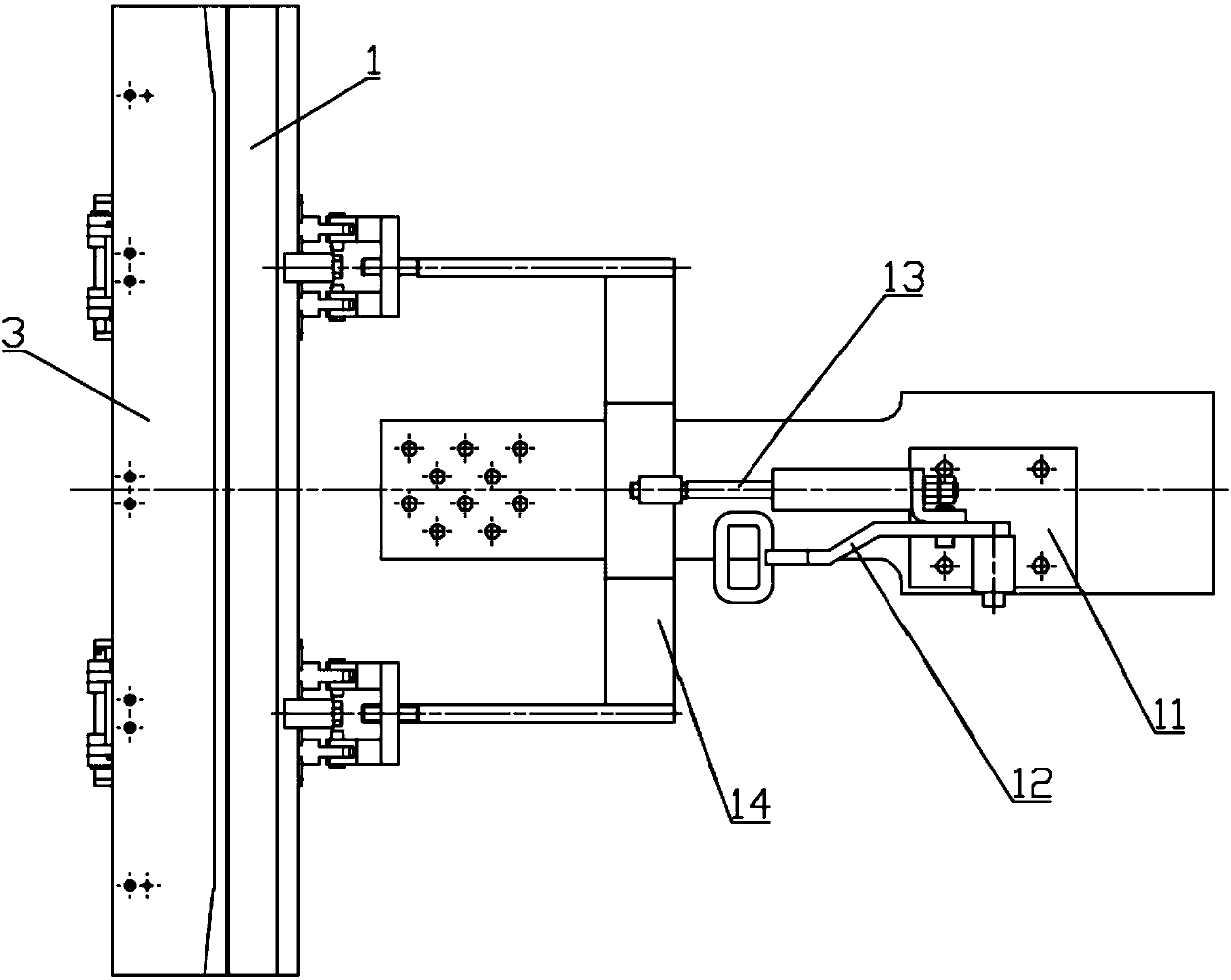

[0021] see Figure 1-7 , a main rail guard rail gap adjustment device, which includes a main rail 1, a guard rail 2 located inside the main rail 1 and a gap adjustment plate 3, and the gap adjustment plate 3 is along the longitudinal direction of the guard rail 2 Extending and having an L-shaped cross-section, the gap adjustment plate 3 is connected to a transmission component, and the transmission component makes the gap adjustment plate 3 in a closed state or an open state. When the gap adjustment plate 3 is in a closed state, the The gap adjustment plate 3 covers the top surface of the guard rail 2 and the side surface of the guard rail 2 opposite to the main rail 1. When the gap adjustment plate 3 is in an open state, the gap adjustment plate 3 is located at the Describe the inside of guard rail 2. It should be noted that the inside is relative to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com