A cryogenic treatment method for suppressing fluffing and pilling of wool fabric

A technology of cryogenic treatment and pilling, which is applied in the treatment of textile materials, solvent treatment, textiles and papermaking, etc., to achieve the effect of soft hand feeling, good gloss and firm texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

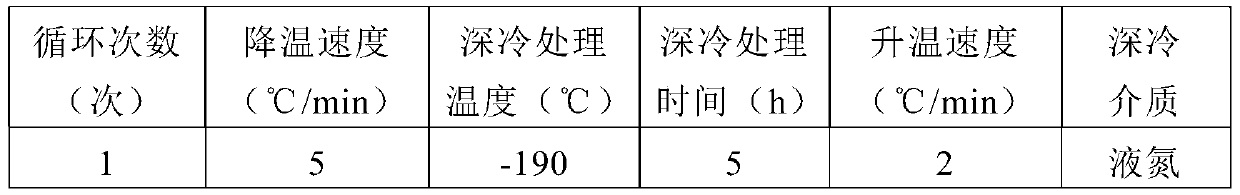

[0029] Embodiment 1 Cryogenic treatment improves the anti-pilling performance of wool knitted fabrics

[0030] Cleaned wool knitted fabrics (Zhejiang Sande Textile Co., Ltd.) were placed in a cryogenic treatment device (SLX-30). Tightly cover the container of the cryogenic treatment equipment to avoid leakage of low-temperature liquid nitrogen, affecting the accuracy of temperature control and treatment effect, and set the cryogenic treatment process parameters, as shown in Table 1. After the treatment is completed, when the ambient temperature of the container reaches room temperature, the wool knitted fabric is taken out, and the modification treatment process is completed.

[0031] The cryogenically treated wool knitted fabrics were tested using the GB / T 4802.2 Determination Standard for Fabric Pilling Properties. The test results are as follows: before cryogenic treatment, the test grade of wool knitted fabric is 2.8, which is a qualified product; after cryogenic treatmen...

Embodiment 2

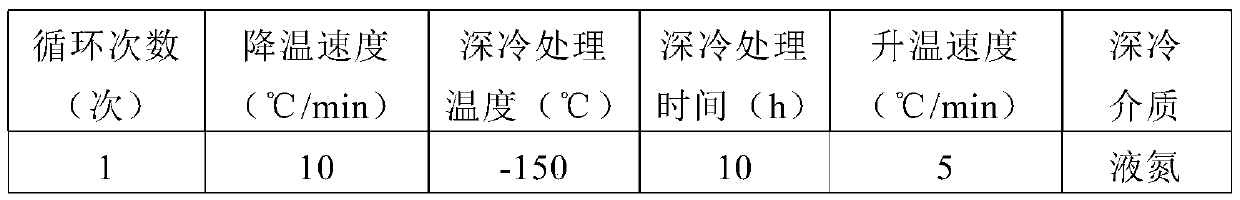

[0034] Embodiment 2 Cryogenic treatment improves the anti-fluffing performance of worsted wool woven fabric

[0035] Cleaned worsted wool woven fabrics (Shandong Nanshan Textile & Garment Co., Ltd.) were placed in cryogenic treatment equipment (SLX-30). Cover the container of the cryogenic treatment equipment tightly to avoid leakage of low-temperature liquid nitrogen, which will affect the accuracy of temperature control and treatment effect, and set the cryogenic treatment parameters according to Table 2.

[0036] After the treatment is completed, when the ambient temperature of the container reaches room temperature, the worsted wool woven fabric is taken out, and the modification treatment process is completed.

[0037] Worsted wool woven fabrics were tested using GB / T 4802.1 Determination Standard for Fabric Pilling Properties. The test results are as follows: before the cryogenic place, the grade of the worsted wool woven fabric is 3.2, which is a qualified product; aft...

Embodiment 3

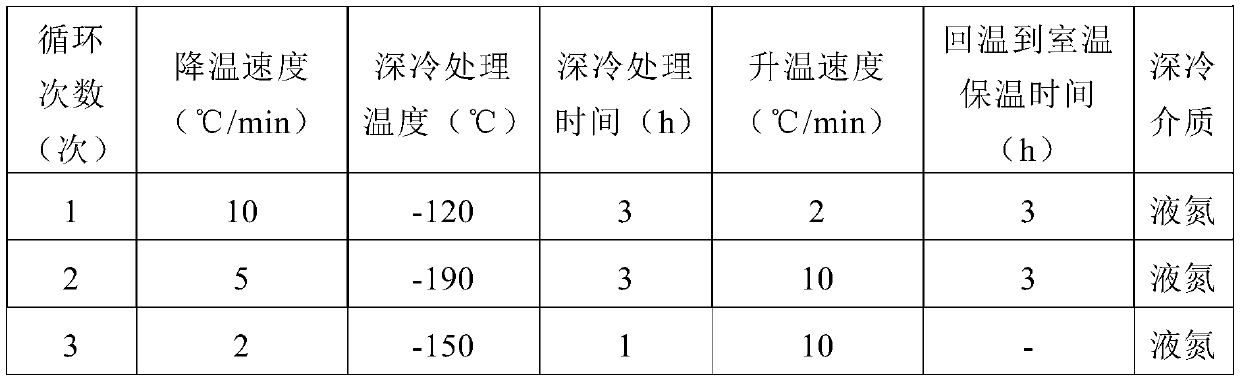

[0040] Example 3 Cyclic cryogenic treatment reduces the pilling performance of wool knitted fabrics

[0041] Cleaned wool knitted fabrics (Zhejiang Sande Textile Co., Ltd.) were placed in a cryogenic treatment device (SLX-30). Tightly cover the container of the cryogenic treatment equipment to avoid leakage of low-temperature liquid nitrogen, affecting the accuracy of temperature control and treatment effect, and set the cryogenic treatment parameters according to Table 3.

[0042] After the treatment is completed, when the ambient temperature of the container reaches room temperature, the wool knitted fabric is taken out, and the modification treatment process is completed.

[0043] The wool knitted fabric is tested by GB / T 4802.2 Determination standard of fabric pilling performance. The test results are as follows: before the cryogenic treatment, the test grade of the wool knitted fabric is 2.8, which is a qualified product; after the cryogenic treatment, the test grade of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com