Combined carding equipment special for yak cashmere

A yak velvet and carding technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of not explaining the basic structure, function and characteristics of key components, and not knowing the carding effect, so as to reduce the damage of yak velvet, Effects of reduced cover load and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

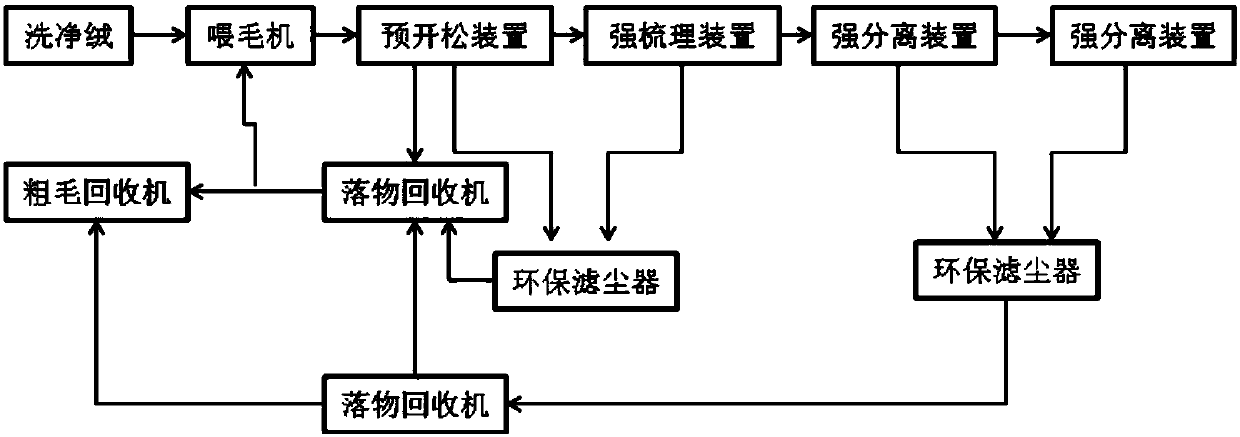

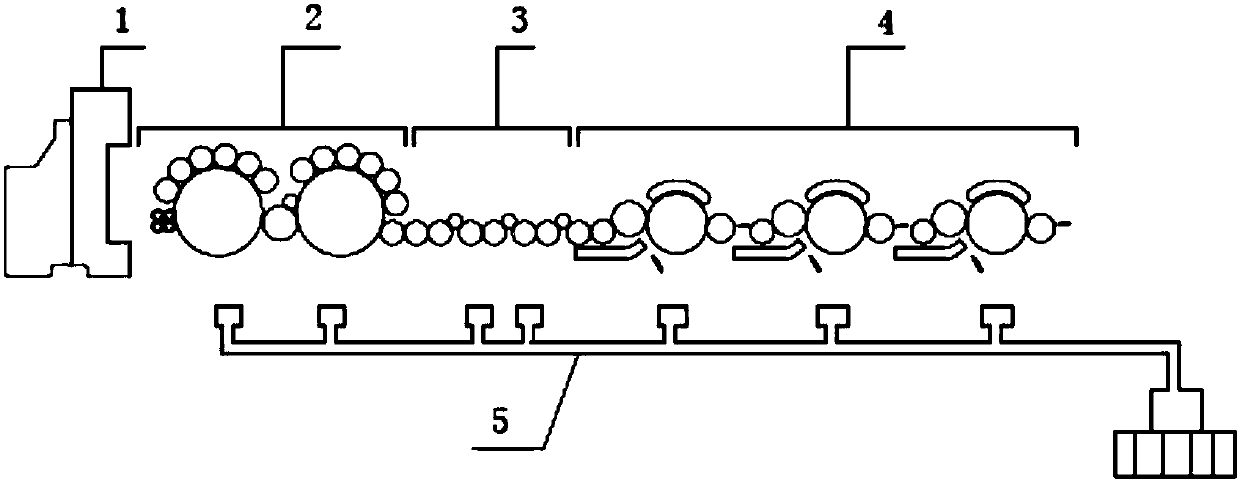

[0037] as attached figure 2 As shown, a special joint carding equipment for yak cashmere is mainly composed of a wool feeding machine 1, a pre-opening device 2, a strong carding device 3, a strong separation device 4, a dust suction and an impurity waste recovery system 5, and the wool feeding The machine 1, the pre-opening device 2, the strong carding device 3, and the strong separation device 4 are arranged in order, and the impurity waste recovery system 5 is located under the pre-opening device 2, the strong carding device 3 and the strong separation device 4.

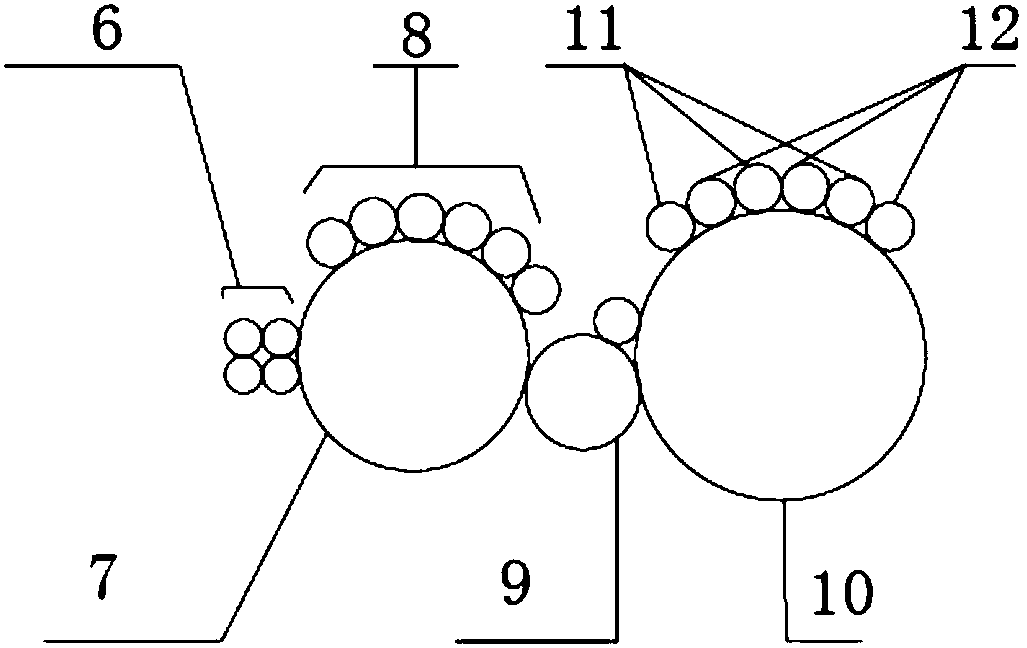

[0038] as attached image 3 As shown, the pre-opening device 2 is mainly composed of a feeding roller group 6, an opening cylinder 7, a finishing roller combination 8, a pre-opening transfer roller 9, an opening cylinder 10, a licker-in roller combination 11, and a pressing roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com