Improved nail shooting device

A nail shooter, an improved technology, applied in the direction of nailing tools, manufacturing tools, etc., can solve the problems of complex firing process, large firing spring force, complex replacement process, etc., to improve firing efficiency and construction efficiency, and elastic force balance and stability , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

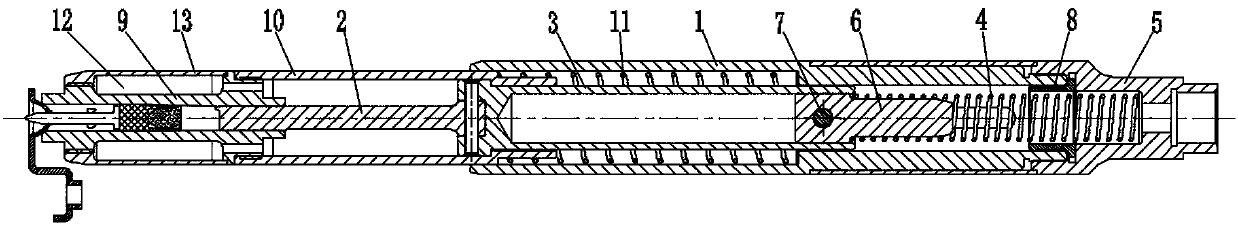

[0023] An improved nail shooter, including a firing mechanism and a nail tube assembly, the firing mechanism includes a sliding sleeve 1, a firing pin 2, a firing pin seat 3, a firing pin seat compression spring 4 and a connecting sleeve 5, the connecting sleeve 5 is fixed on One end of the sliding sleeve 1, the nail tube assembly is movably arranged at the other end of the sliding sleeve 1, one end of the firing pin 2 is located in the nail tube 9 of the nail tube assembly, and the other end is fixedly connected with the firing pin seat 3, and the firing pin seat 3 The activity is arranged in the sliding sleeve 1, and the pressing spring 4 of the firing pin seat is arranged between the firing pin seat 3 and the connecting sleeve 5.

[0024] In this embodiment, the sliding sleeve 1 is provided with a compression spring seat 6. The compression spring seat 6 includes a large cylindrical end and a small cylindrical end integrally formed. The large cylinder of the compression sprin...

Embodiment 2

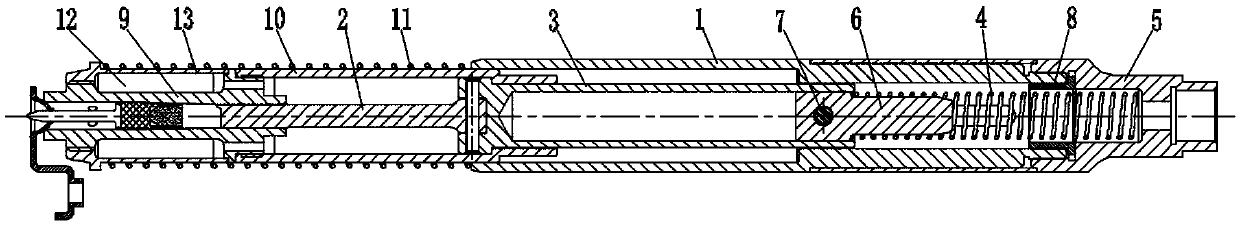

[0028] An improved nail shooter, including a firing mechanism and a nail tube assembly, the firing mechanism includes a sliding sleeve 1, a firing pin 2, a firing pin seat 3, a firing pin seat compression spring 4 and a connecting sleeve 5, the connecting sleeve 5 is fixed on One end of the sliding sleeve 1, the nail tube assembly is movably arranged at the other end of the sliding sleeve 1, one end of the firing pin 2 is located in the nail tube 9 of the nail tube assembly, and the other end is fixedly connected with the firing pin seat 3, and the firing pin seat 3 The activity is arranged in the sliding sleeve 1, and the pressing spring 4 of the firing pin seat is arranged between the firing pin seat 3 and the connecting sleeve 5.

[0029] In this embodiment, the sliding sleeve 1 is provided with a compression spring seat 6. The compression spring seat 6 includes a large cylindrical end and a small cylindrical end integrally formed. The large cylinder of the compression sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com