TiB<2>-coated lithium nickel cobalt manganate positive electrode material and preparation method therefor

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the field of lithium-ion battery positive electrode materials and its preparation, and achieves the effects of simple operation, low cost, and increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

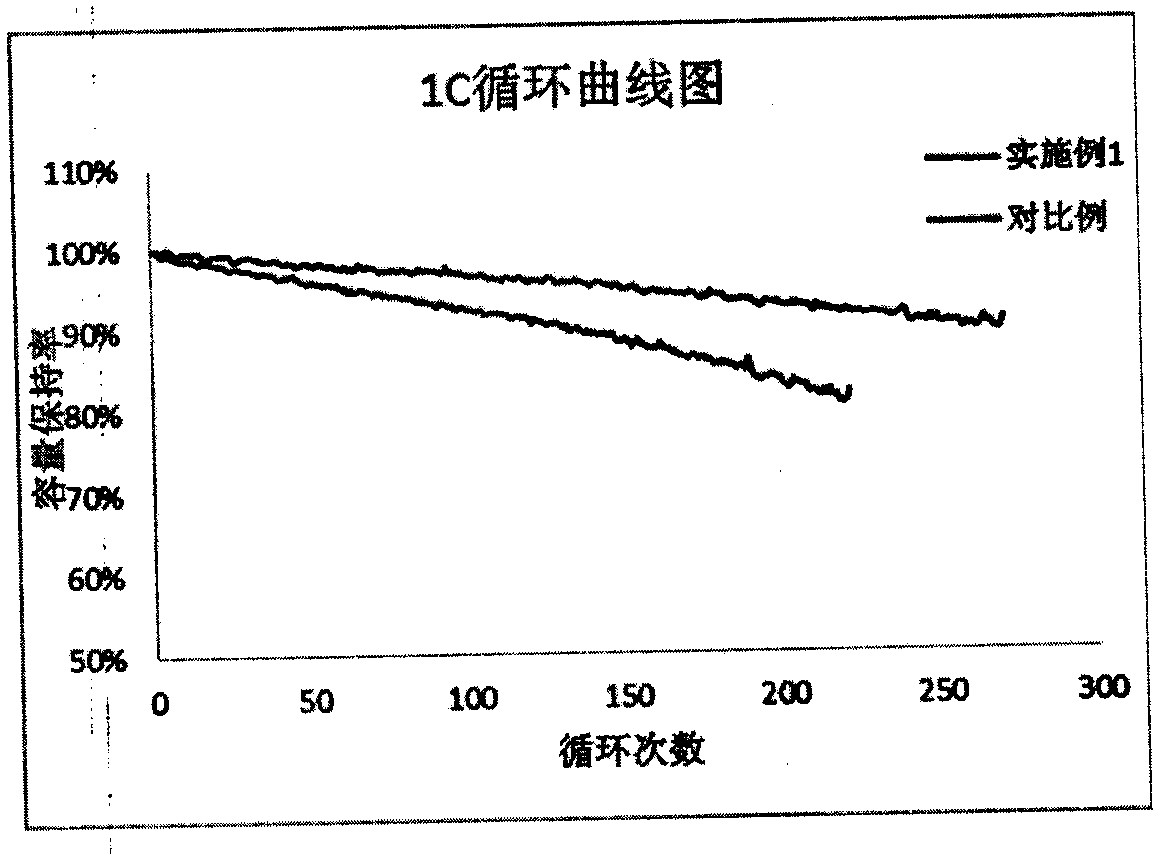

Embodiment 1

[0030] The nickel cobalt lithium manganese oxide LiNi prepared in the comparative example 0.5 co 0.2 mn 0.3 o 2 TiB with an average primary particle size of 100-500nm 2 Dry Blend, LiNi 0.5 co 0.2 mn 0.3 o 2 with TiB 2 According to the mass ratio of 1000:5, put it into the ball milling tank lined with polytetrafluoroethylene, use agate balls according to the ball material mass ratio of 1:4.5, and ball milling mixing and coating at the speed of 250 rpm in the ball milling tank After 2 hours, put the mixed powder into a sagger and smooth it, sinter at 820°C for 6 hours in an air atmosphere, cool naturally after completion, take out the powder and sieve to obtain TiB 2 Coated LiNi 0.5 co 0.2 mn 0.3 o 2 Sample S523T-1.

Embodiment 2

[0032] The nickel cobalt lithium manganese oxide LiNi prepared in the comparative example 0.5 co 0.2 mn 0.3 o 2 TiB with an average primary particle size of 500-1000nm 2 Dry Blend, LiNi 0.5 co 0.2 mn 0.3 o 2 with TiB 2 According to the mass ratio of 1000:5, put it into the ball milling tank lined with polytetrafluoroethylene, use agate balls according to the ball material mass ratio of 1:4.5, and ball milling mixing and coating at the speed of 250 rpm in the ball milling tank After 2 hours, put the mixed powder into a sagger and smooth it, sinter at 820°C for 6 hours in an air atmosphere, cool naturally after completion, take out the powder and sieve to obtain TiB 2 Coated LiNi 0.5 co 0.2 mn 0.3 o 2 Sample S523T-2.

Embodiment 3

[0034] The nickel-cobalt lithium manganese oxide LiNi prepared by sintering 0.6 co 0.2 mn 0.2 o 2 TiB with an average primary particle size of 100-500nm 2 Dry Blend, LiNi 0.6 co 0.2 mn 0.6 o2 with TiB 2 According to the mass ratio of 1000:5, put it into the ball milling tank lined with polytetrafluoroethylene, use agate balls according to the ball material mass ratio of 1:4.5, and ball milling mixing and coating at the speed of 250 rpm in the ball milling tank After 2 hours, put the mixed powder into a sagger and smooth it, sinter at 780°C for 6 hours in an air atmosphere, cool naturally after completion, take out the powder and sieve to obtain TiB 2 Coated LiNi 0.6 co 0.2 mn 0.6 o 2 Sample S622T-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com