Wireless temperature measurement control system of natural lustre finishing machine and control method thereof

A wireless temperature measurement and control system technology, applied in the field of ironing machines, can solve the problems of poor contact between the brush and the collector ring, inaccurate temperature control of the ironing roller, wear of the collector ring and the brush, etc., to avoid temperature signals. Distortion, reduce equipment maintenance costs, and stabilize the effect of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

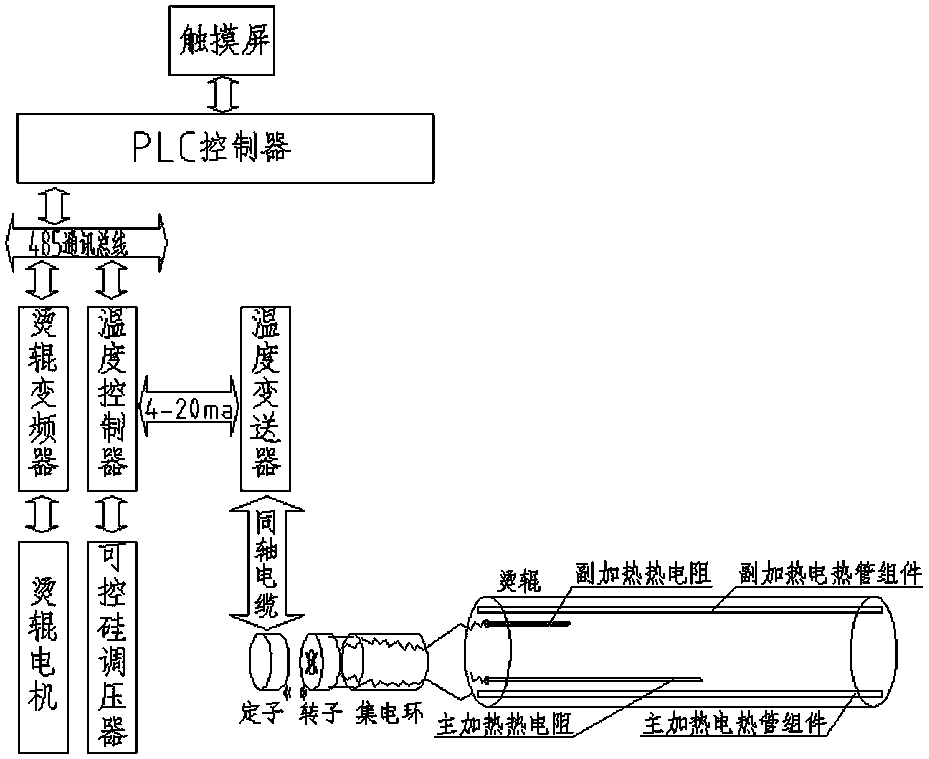

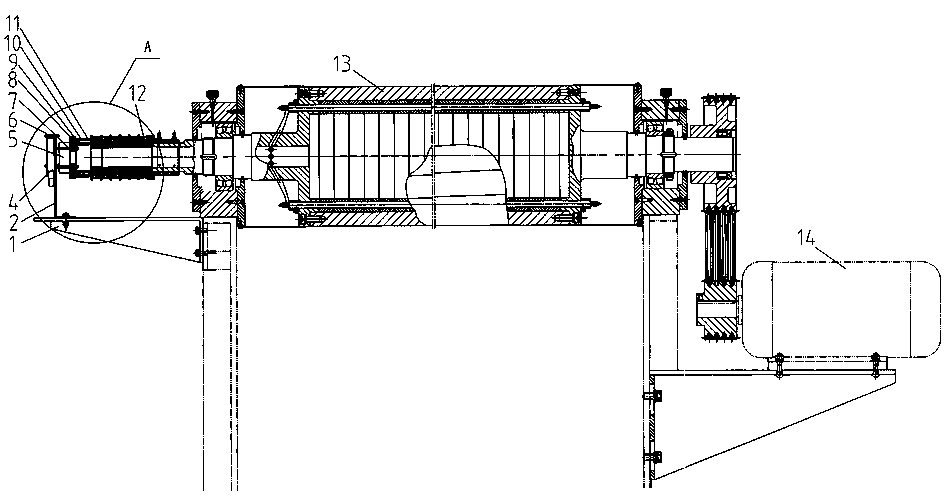

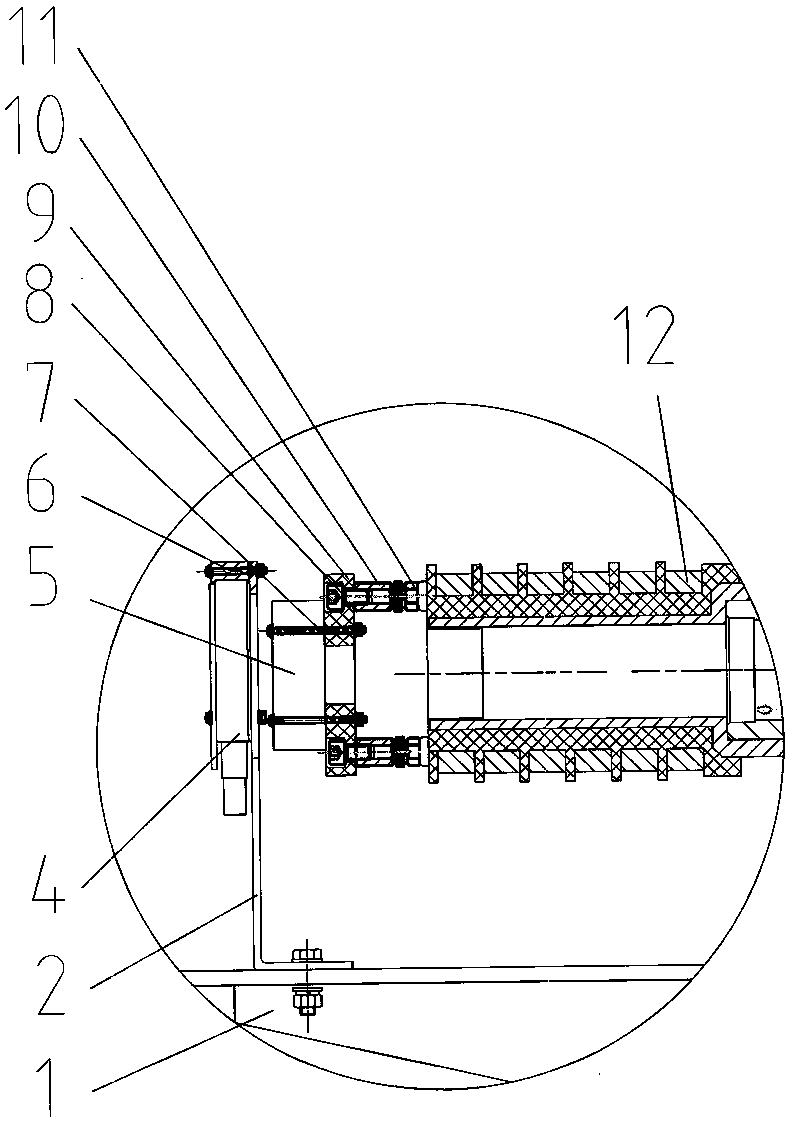

[0020] Such as figure 1 As shown, a wireless temperature measurement control system for ironing machines includes a PLC controller, a touch screen, an intelligent temperature controller, an ironing roller inverter connected to the ironing roller motor, a silicon controlled voltage regulator, and a The main heating electric heating tube assembly, the auxiliary heating electric heating tube assembly, the main heating temperature measuring thermal resistance, the auxiliary heating temperature measuring thermal resistance, the electric heating collector ring, and a wireless temperature measuring control system. The wireless temperature measuring system includes a wireless temperature measuring Temperature rotor, wireless temperature measurement stator, temperature transmitter. The main heating temperature-measuring thermal resistor and the auxiliary heating temperature-measuring thermal resistor are respectively embedded in different radial positions inside the ironing roller, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com