Micro-duplicate gear tooth break defect detecting method based on gear center distance curves

A dual-gear and curve analysis technology, which is applied in the direction of material analysis, image analysis, optical test flaws/defects, etc., can solve the problems of poor adaptability and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

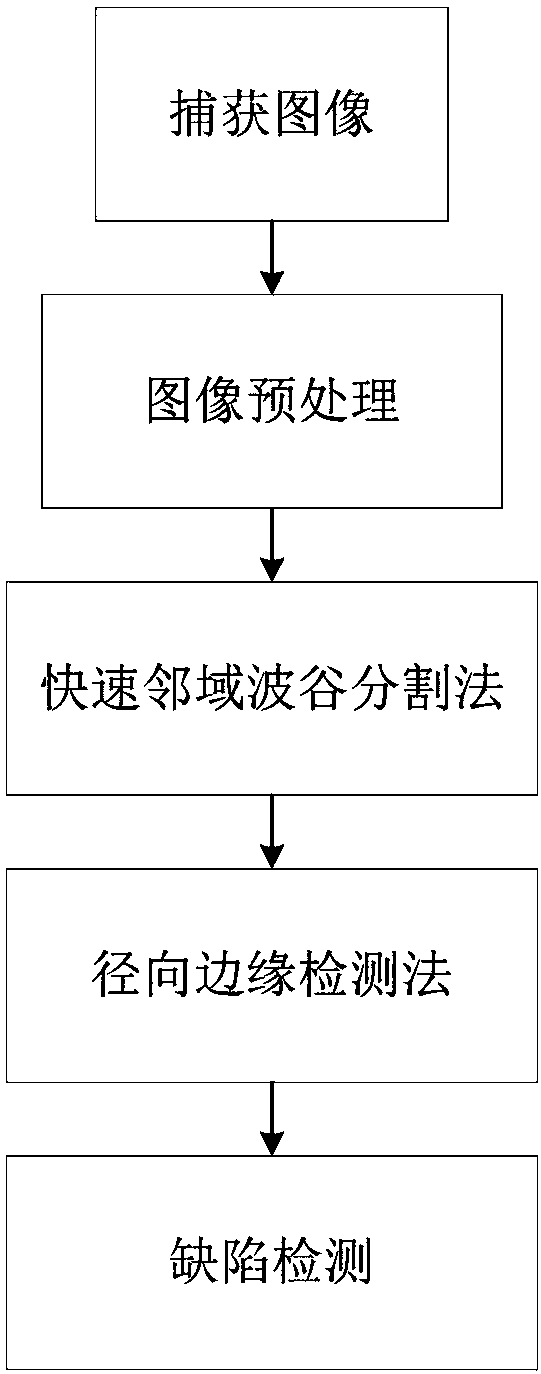

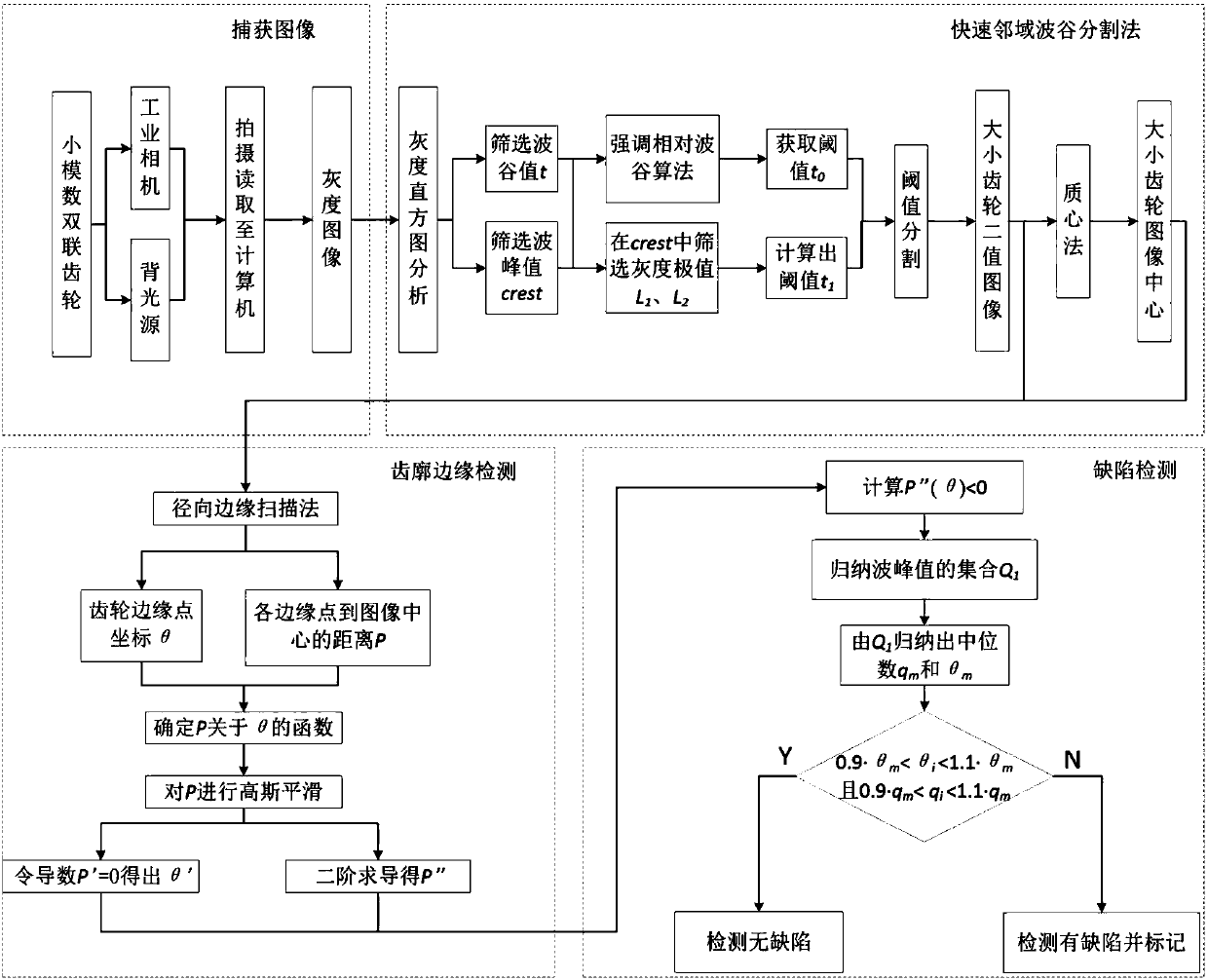

[0083] Such as image 3 Shown, according to the embodiment that the summary of the invention implements method and implementation process thereof are as follows:

[0084] A number of miniature double gears with a modulus of 0.5 mm are used as the experimental objects. The following is an example of a 46 (10) tooth double gear with a broken tooth defect in each of the large and small gears. The implementation process specifically includes the following:

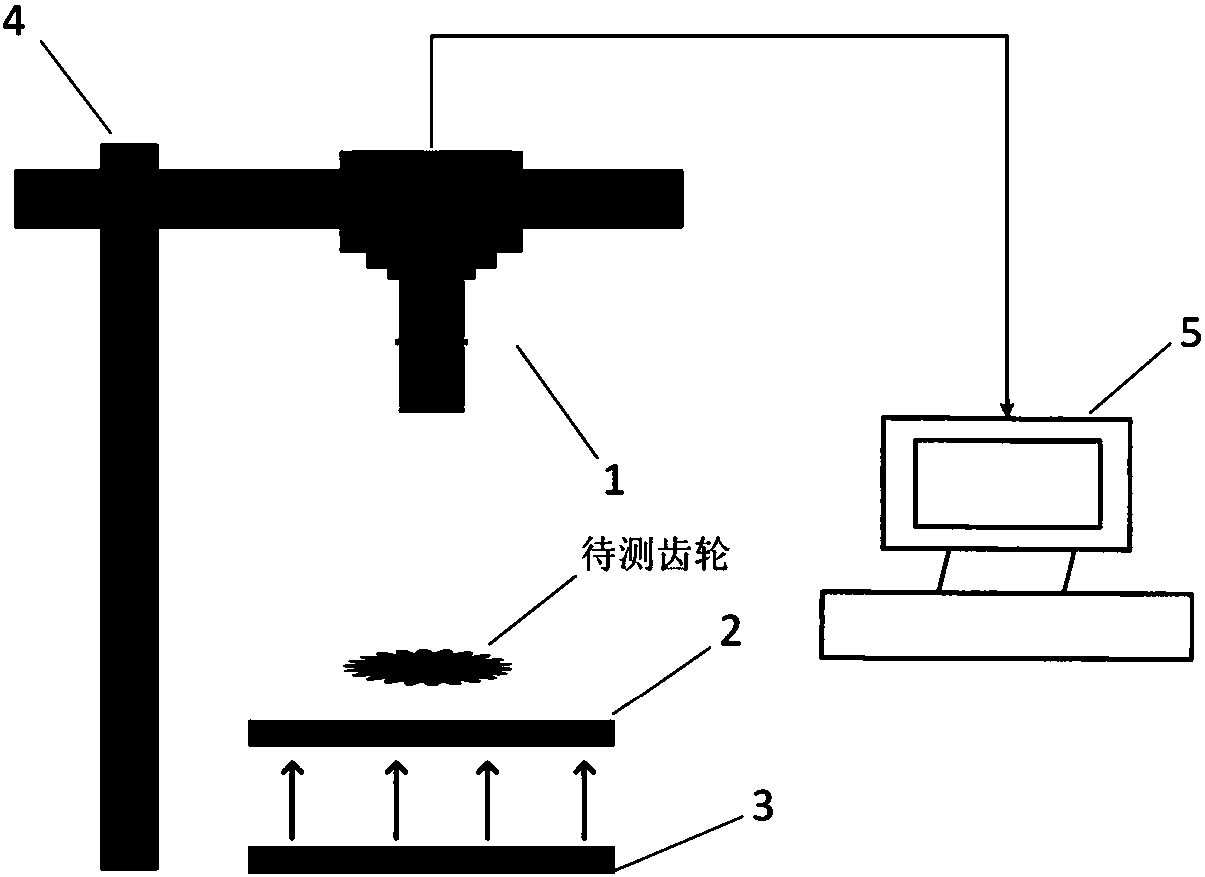

[0085] Step 1): If figure 1 As shown, in the specific implementation, a miniature dual injection molding gear visual defect detection system is constructed. The system includes an industrial camera 1, a backlight 2, a workbench 3, a camera position adjustment bracket 4 and a PC terminal 5, and the test system is built a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com