Adjustable oil-air lubrication nozzle kit

An oil-air lubrication and adjustable technology, which is applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve problems affecting test efficiency, etc., and achieve the effects of improving test efficiency, simple structure, and reducing machine hours and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

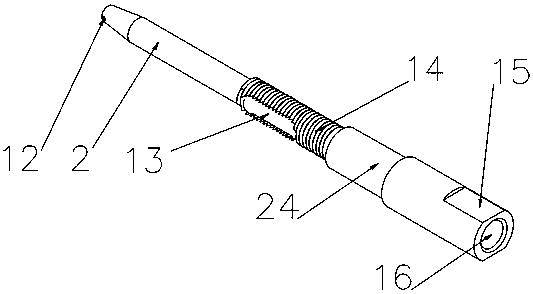

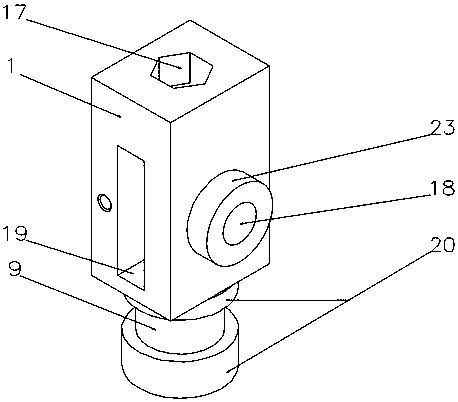

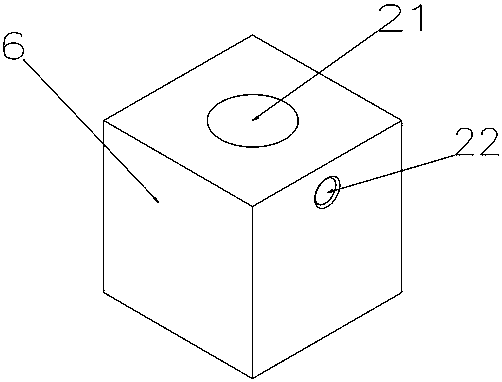

[0026] An adjustable oil-air lubrication nozzle kit includes a tubular nozzle body 2 and a nozzle bracket for supporting the nozzle body 2 .

[0027] Such as figure 1 As shown, the cavity inside the nozzle main body 2 forms an oil-gas channel 11, and the middle part of the outer peripheral side of the nozzle main body 2 is provided with an external thread 14, the pitch of which is 1 mm, and the external thread 14 is provided with a groove extending along the length direction of the nozzle main body 2. The limit groove 13 of the outer thread 14 is provided with a distance adjustment dial 4 and a nozzle lock nut 5, and the inner hole of the distance adjustment dial 4 is provided with an internal thread matching the outer thread 14, and the distance adjustment dial 4 The outer wall is provided with non-slip embossing. The part of the nozzle body 2 clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com