High-lubrication micro-foam drilling fluid and preparation method thereof

A drilling fluid and foam technology, which is applied in the field of high lubricating foam drilling fluid and its preparation, can solve the problems of restricting the application of micro-foam drilling fluid, poor foam stability, application limitation, etc., and achieves excellent anti-pollution performance, low cost and wide source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of high-lubricating micro-foam drilling fluid, its raw materials are proportioned as follows in parts by weight: 12 parts of sodium bentonite, 0.3 parts of sodium hydroxide, 140 parts of water, 5 parts of xanthan gum, and 2 parts of high-viscosity carboxymethyl cellulose sodium , 1 part of aluminum oxide, 1 part of polyquaternium sodium, 10 parts of sodium sulfonate, 2 parts of carboxymethyl cellulose, 0.5 part of nano-titanium chloride, 0.5 part of polyphenylene ether, 0.1 part of sodium lauryl sulfate, Octadecene succinic acid 5 parts.

[0023] The preparation method of the drilling fluid is specifically as follows: at normal temperature and pressure, add each component in turn and weigh according to the above-mentioned proportions, mix evenly and stir for 2 hours at a stirring speed of 1000r / min to obtain the product.

Embodiment 2

[0025] A kind of high-lubricating micro-foam drilling fluid, its raw materials are proportioned as follows by weight: 10 parts of calcium-based bentonite, 0.25 parts of sodium hydroxide, 110 parts of water, 5 parts of xanthan gum, and 3 parts of high-viscosity carboxymethyl cellulose sodium , 3 parts of aluminum oxide, 3 parts of polyquaternium sodium, 12 parts of potassium sulfonate, 4 parts of carboxymethyl cellulose, 0.7 parts of nano-titanium chloride, 0.7 parts of polyphenylpropyl ether, 0.3 parts of sodium lauryl sulfate, Octadecene succinic acid 7 parts.

[0026] The preparation method of the drilling fluid is specifically as follows: at normal temperature and pressure, add each component in turn and weigh according to the above-mentioned proportions, mix evenly and stir for 6 hours at a stirring speed of 1000r / min to obtain the product.

Embodiment 3

[0028] A kind of high-lubricating micro-foam drilling fluid, its raw materials are proportioned as follows in parts by weight: 8 parts of sodium bentonite, 0.2 parts of sodium hydroxide, 100 parts of water, 5 parts of xanthan gum, and 4 parts of high-viscosity carboxymethyl cellulose sodium , 5 parts of aluminum oxide, 1 part of polyquaternium sodium, 15 parts of calcium sulfonate, 6 parts of carboxymethyl cellulose, 1 part of nano-titanium chloride, 1 part of polyphenylene dimethyl ether, 0.5 part of sodium lauryl sulfate , 10 parts of octadecyl succinic acid.

[0029] The preparation method of the drilling fluid is specifically as follows: at normal temperature and pressure, add each component in turn and weigh according to the above-mentioned proportions, mix evenly and stir for 4 hours at a stirring speed of 800r / min to obtain the product.

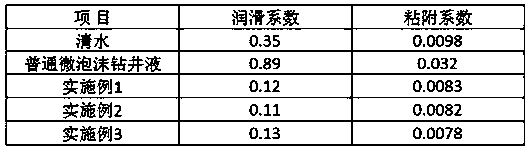

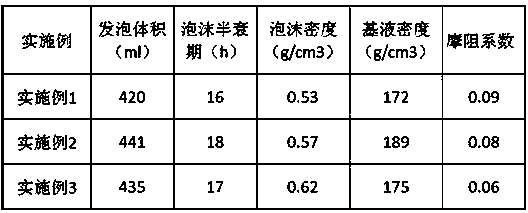

[0030] 1. The microfoam drilling fluid in the above-mentioned embodiment is detected, and the detection results are shown in Table 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com