Extraction method and application of grub polysaccharide

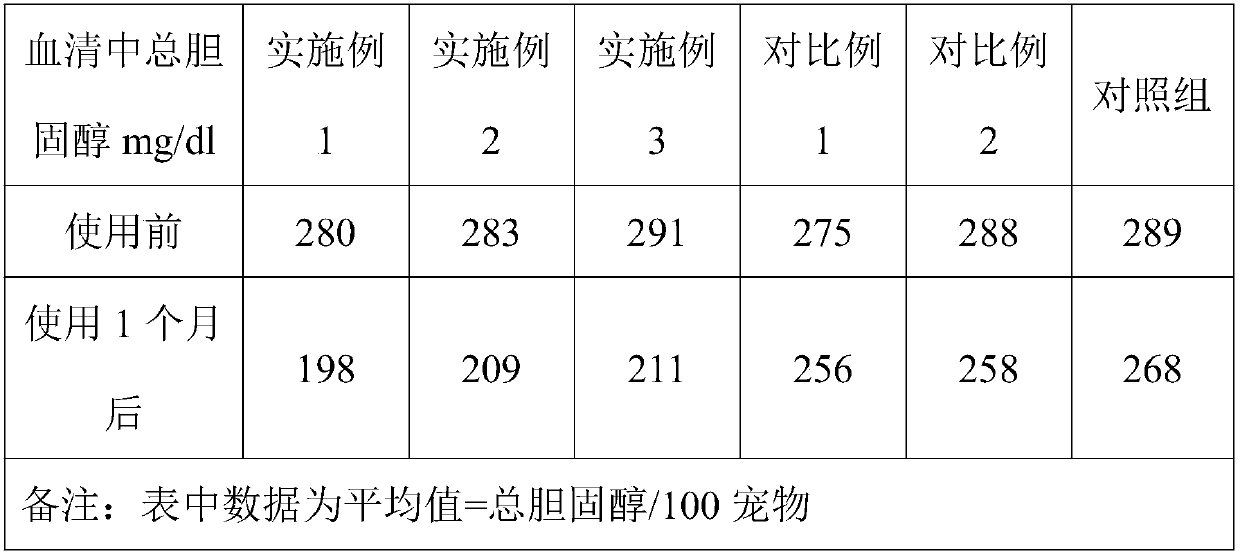

An extraction method, grub technology, applied in the field of polysaccharide extraction, can solve the problems of extraction efficiency impact, polysaccharide degreasing, etc., and achieve the effect of reducing blood fat and health care, low price, and no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for extracting polysaccharides from grubs, comprising the steps of:

[0026] (1) Wash the grub, dry and pulverize it at 60°C, and pass through a 30-mesh sieve to obtain the grub dry powder;

[0027] (2) Take the grub dry powder in step (1), add petroleum ether to degrease, the mass volume ratio (g / mL) of the grub dry powder to petroleum ether is 1:6.5, dry after degreasing, obtain the defatted grub dry powder;

[0028] (3) Take the degreased grub dry powder of step (2), add 0.02mol / L NaOH solution, the mass volume ratio (g / mL) of defatted grub dry powder and NaOH solution is 1:13, 70 ℃ of water bath stirring and extracting 3 times, each time 2h, after filtering, combine the filtrate, adjust the pH of the filtrate to neutral, and concentrate under reduced pressure to 1 / 7.5 of the original volume;

[0029] (4) Take the concentrated solution of step (3), add 4 times the volume of 95% ethanol, put it in the refrigerator overnight, centrifuge, collect the precipita...

Embodiment 2

[0032] A method for extracting polysaccharides from grubs, comprising the steps of:

[0033] (1) Wash the grub, dry and pulverize it at 60°C, and pass through a 20-mesh sieve to obtain the grub dry powder;

[0034] (2) Take the grub dry powder in step (1), add petroleum ether to degrease, the mass volume ratio (g / mL) of the grub dry powder to petroleum ether is 1:10, dry after degreasing, obtain the defatted grub dry powder;

[0035] (3) Take the degreased grub dry powder of step (2), add 0.02mol / L NaOH solution, the mass volume ratio (g / mL) of defatted grub dry powder and NaOH solution is 1:20, 90 ℃ of water baths are stirred and extracted 3 times, each time 1h, after filtering, combine the filtrate, adjust the pH of the filtrate to neutral, and concentrate under reduced pressure to 1 / 5 of the original volume;

[0036] (4) Take the concentrated solution of step (3), add 4 times the volume of 95% ethanol, put it in the refrigerator overnight, centrifuge, collect the precipita...

Embodiment 3

[0039] A method for extracting polysaccharides from grubs, comprising the steps of:

[0040] (1) Wash the grub, dry and pulverize it at 60°C, and pass through a 40-mesh sieve to obtain the grub dry powder;

[0041] (2) Take the grub dry powder in step (1), add petroleum ether to degrease, the mass volume ratio (g / mL) of the grub dry powder to petroleum ether is 1:3, dry after degreasing, and obtain the degreased grub dry powder;

[0042] (3) Take the degreased grub dry powder in step (2), add 0.02mol / L NaOH solution, the mass volume ratio (g / mL) of defatted grub dry powder to NaOH solution is 1:5, stir and extract in a 50°C water bath for 3 times, each time 3h, after filtering, combine the filtrate, adjust the pH of the filtrate to neutral, and concentrate under reduced pressure to 1 / 10 of the original volume;

[0043] (4) Take the concentrated solution of step (3), add 4 times the volume of 95% ethanol, put it in the refrigerator overnight, centrifuge, collect the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com