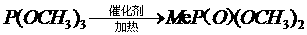

Method for synthesizing dimethyl methylphosphate

A technology of dimethyl methyl phosphate and trimethyl phosphite, which is applied in the field of synthesis of alkyl phosphate compounds, can solve the problem of low reaction yield and achieve the effects of high product purity, convenient operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Lewis Acid Ionic Liquid [BuPy]Cl-AlCl 3 Preparation of (BuPy=N-butylpyridinium cation):

[0030] Install a stirrer on the reaction kettle, add 26.64g (0.2mol) of anhydrous aluminum chloride under nitrogen protection, and add 17.1g (0.1mol) of n-butylpyridine chloride in batches. After adding the quaternary ammonium salt, keep stirring at about 60°C for 3 hours to ensure the reaction is complete, and a transparent light brown [BuPy]Cl-AlCl is obtained 3 ionic liquid.

[0031] The second step: the preparation of dimethyl methyl phosphate

[0032] (1) Install a stirrer on the reaction kettle, and equip it with a cold circulation cooling system to ensure reflux. Put in the above-mentioned ionic liquid and 124g (1mol) trimethyl phosphite to heat and reflux, then raise the temperature to 80°C-100°C, and control the pressure at 1.1 - Between 2.1 atmospheric pressure, after reacting for 6 hours, the conversion rate of raw materials detected by GC was 99%.

[0033] (...

Embodiment 2

[0039] Step 1: Ionic liquid [Et 3 NH]Cl-AlCl 3 (Et 3 Preparation of NH = hydrogenated triethylamine cation):

[0040] Install a stirrer on the reaction kettle, add 26.64g (0.2mol) of anhydrous aluminum chloride under nitrogen protection, and add 13.8g (0.1mol) of triethylamine hydrochloride in batches. After adding the quaternary ammonium salt, keep stirring at about 120°C for 2 hours to ensure that the reaction is complete, and a transparent and colorless [Et 3 NH]Cl-AlCl 3 ionic liquid.

[0041] The second step: the preparation of dimethyl methyl phosphate

[0042] (1) Install a stirrer on the reaction kettle, and equip it with a cold circulation cooling system to ensure reflux. Put in the above-mentioned ionic liquid and 124g (1mol) trimethyl phosphite to heat and reflux, then raise the temperature to 80°C-100°C, and control the pressure at 1.2 - Between 1.5 atmospheric pressure, after reacting for 4 hours, the conversion rate of raw materials detected by GC was 99.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com