Method for preparing feed-grade fructo-oligosaccharide by taking molasses as raw material

A technology of fructooligosaccharides and feed grade, which is applied in the field of preparing feed grade fructooligosaccharides, can solve the problems of application limitation of fructooligosaccharides, restricting industrial development, long reaction time, etc., and achieves good appearance, improved utilization rate, and reaction time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a kind of method using molasses as raw material to prepare feed grade fructo-oligosaccharides, the method may further comprise the steps:

[0036] (1) Preparation of molasses aqueous solution: take a certain amount of molasses to prepare an aqueous solution, wherein the mass ratio of molasses to water is 2:1, mix the molasses with water and stir until the molasses is completely dissolved in water to obtain the molasses aqueous solution for subsequent use;

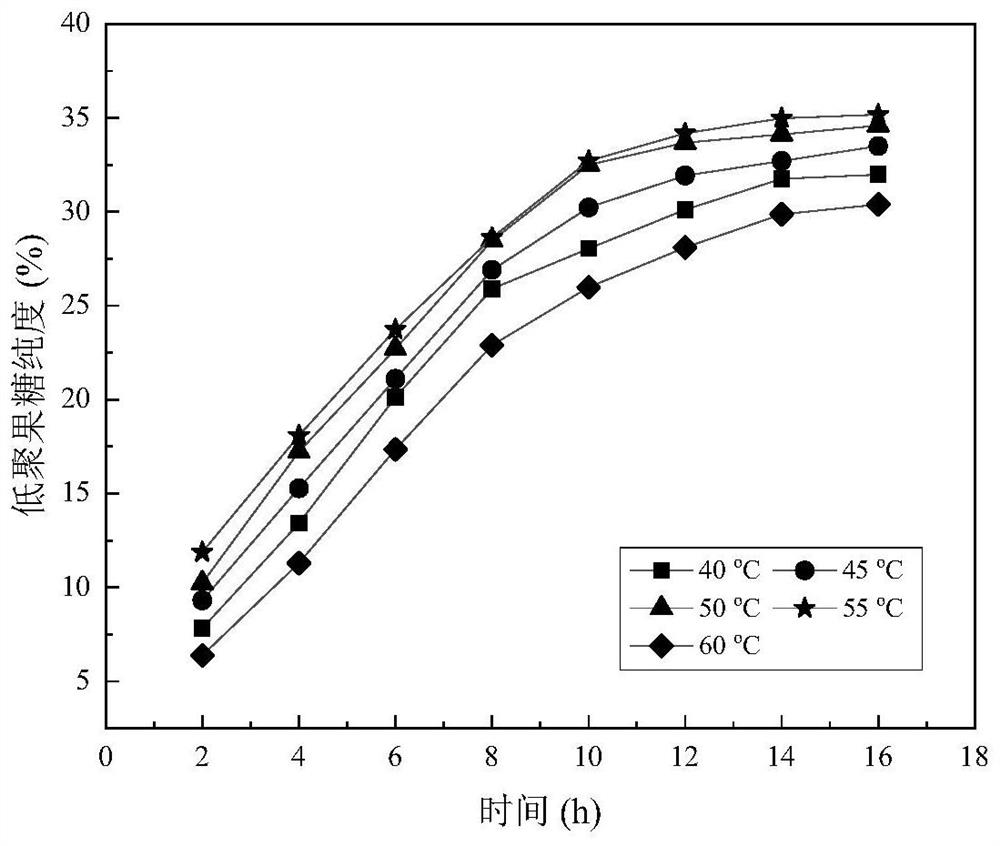

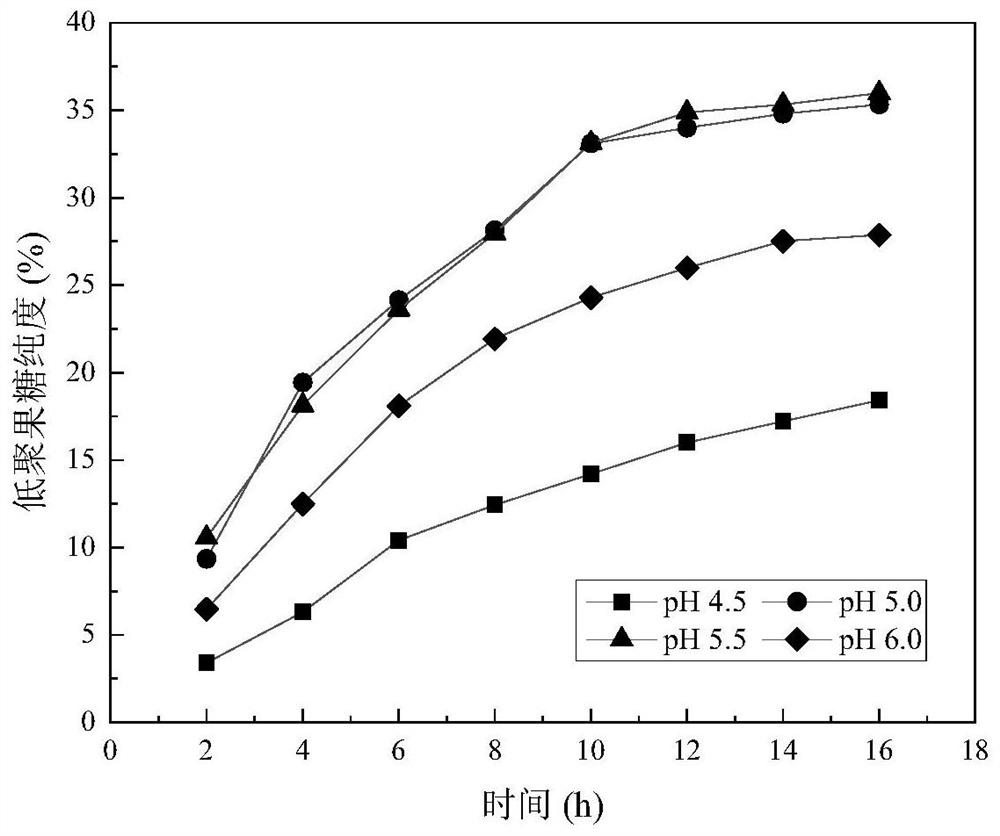

[0037] (2) Pretreatment of molasses aqueous solution: adjust the temperature of molasses aqueous solution to be 40° C., and the pH to be 5.0;

[0038] (3) Enzymolysis: add enzymolysis solution to the molasses aqueous solution pretreated in step (2), stir evenly, and react for 9 hours under the assistance of microwaves. The microwave power is 950W, and the frequency is 700MHz. After the above treatment, Enzymolysis solution, for use; the enzymolysis solution includes pectinase and fruct...

Embodiment 2

[0044] The present embodiment provides a kind of method using molasses as raw material to prepare feed grade fructo-oligosaccharides, the method may further comprise the steps:

[0045] (1) Preparation of molasses aqueous solution: take a certain amount of molasses to prepare an aqueous solution, wherein the mass ratio of molasses to water is 3:1, mix the molasses with water and stir until the molasses is completely dissolved in water to obtain the molasses aqueous solution for subsequent use;

[0046] (2) Pretreatment of molasses aqueous solution: adjust the temperature of molasses aqueous solution to be 50° C., and the pH to be 5.5;

[0047] (3) Enzymolysis: add enzymolysis solution to the molasses aqueous solution pretreated in step (2), stir evenly, and react for 10 hours under the assistance of microwaves. The microwave power is 850W, and the frequency is 750MHz. After the above treatment, Enzymolysis solution, for use; the enzymolysis solution includes pectinase and fruc...

Embodiment 3

[0053] The present embodiment provides a kind of method using molasses as raw material to prepare feed grade fructo-oligosaccharides, the method may further comprise the steps:

[0054] (1) Preparation of molasses aqueous solution: take a certain amount of molasses to prepare an aqueous solution, wherein the mass ratio of molasses to water is 4:1, mix the molasses with water and stir until the molasses is completely dissolved in water to obtain the molasses aqueous solution for subsequent use;

[0055] (2) Pretreatment of molasses aqueous solution: adjust the temperature of molasses aqueous solution to be 60° C., and the pH to be 5.5;

[0056] (3) Enzymolysis: add enzymolysis solution to the molasses aqueous solution pretreated in step (2), stir evenly, and react for 11 hours under the assistance of microwave. The microwave power is 1000W, and the frequency is 800MHz. After the above treatment, Enzymolysis solution, for use; the enzymolysis solution includes pectinase and fruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com