A kind of method of producing chloride-free, fluoride-free sodium tripolyphosphate

A technology of sodium tripolyphosphate and fluoride, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as excessive production cost and energy consumption, limit large-scale application, etc., and achieve low cost and high yield big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First add 5 tons of water into the neutralization pot, heat it to 80°C with steam, add 4.5 tons of industrial grade soda ash, stir to completely dissolve the soda ash, and when the temperature of the solution rises to 90°C, slowly add 85% wet-process phosphoric acid and 3.5 tons of solid sodium carbonate were reacted, and the neutralization degree K value of the neutralizing solution was adjusted to 2.6 to stop acid addition, and the amount of phosphoric acid added was measured by a metering pump. Control the specific gravity of the neutralized slurry at 1.4, add silicon dioxide, continue the reaction for 3 hours, send it to the drying tower after fine filtration, and polymerize at a reaction temperature of 380°C to form sodium tripolyphosphate. After the tail gas passes through the alkali washing tower to collect impurity gas, it is emptied.

[0037] In the above reaction, silicon dioxide is added according to 0.1% of the mass of phosphoric acid. The overall reaction ...

Embodiment 2

[0045] First add 10 tons of water into the neutralization pot, heat it to 80°C with steam, add 6 tons of industrial grade soda ash, stir to completely dissolve the soda ash, when the temperature of the solution rises to 100°C, slowly add wet-process phosphoric acid and 7 tons of The soda ash is reacted, and the neutralization degree K value of the neutralizing solution is adjusted to 2.8 to stop acid addition, and the amount of phosphoric acid added is measured by a metering pump. Control the specific gravity of the neutralized slurry at 1.5, add silicon dioxide, continue the reaction for 3.5 hours, send it into the drying tower after fine filtration, and polymerize at a reaction temperature of 400°C to form sodium tripolyphosphate. After the tail gas passes through the alkali washing tower to collect impurity gas, it is emptied.

[0046] Silica is added according to 0.3% of phosphoric acid mass.

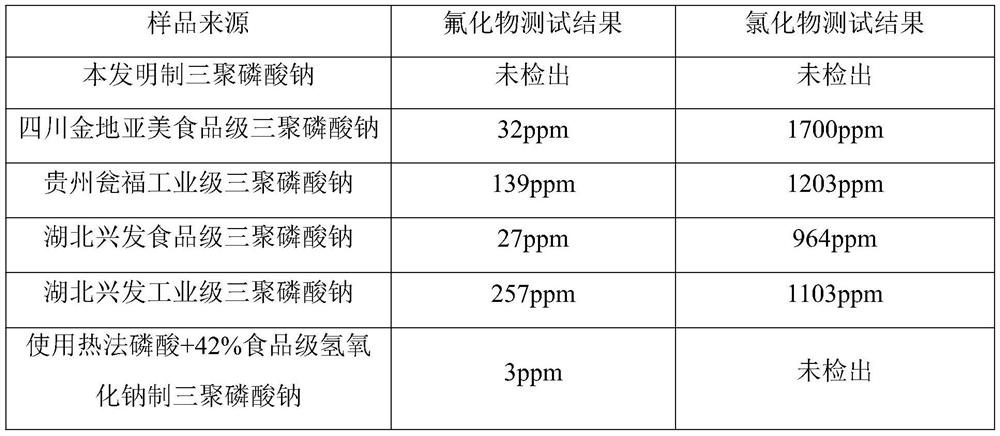

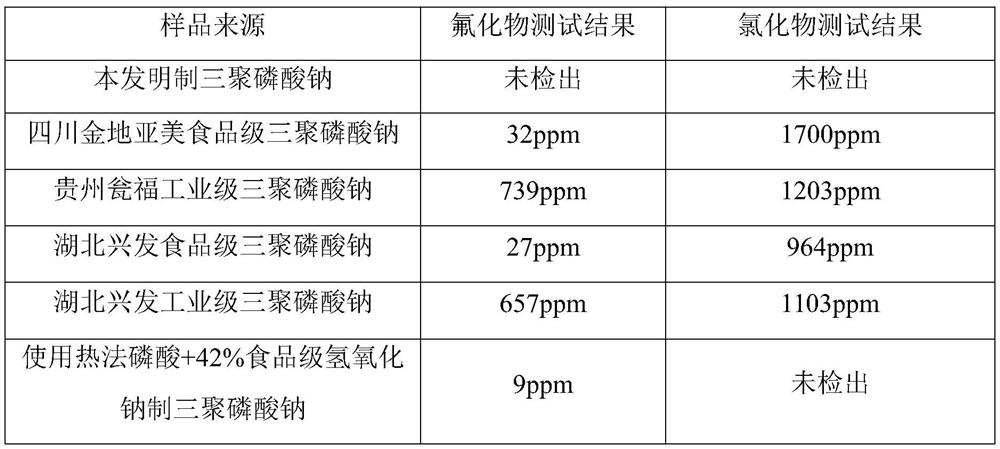

[0047] Fluoride test method: According to GB25566-2010 national food safety stan...

Embodiment 3

[0051] First add 15 tons of water into the neutralization pot, heat to 80°C with steam, add 12 tons of industrial grade soda ash, stir to completely dissolve the soda ash, when the temperature of the solution rises to 110°C, slowly add wet-process phosphoric acid and 10 tons of The solid sodium carbonate is reacted, and the neutralization degree K value of the neutralizing solution is adjusted to 3.0 to stop acid addition, and the amount of phosphoric acid added is metered by a metering pump. Control the specific gravity of the neutralized slurry at 1.6, add silicon dioxide, continue the reaction for 4 hours, send it to the drying tower after fine filtration, and polymerize at a reaction temperature of 420°C to form sodium tripolyphosphate. After the tail gas passes through the alkali washing tower to collect impurity gas, it is emptied.

[0052] Silica is added according to 0.5% of phosphoric acid mass.

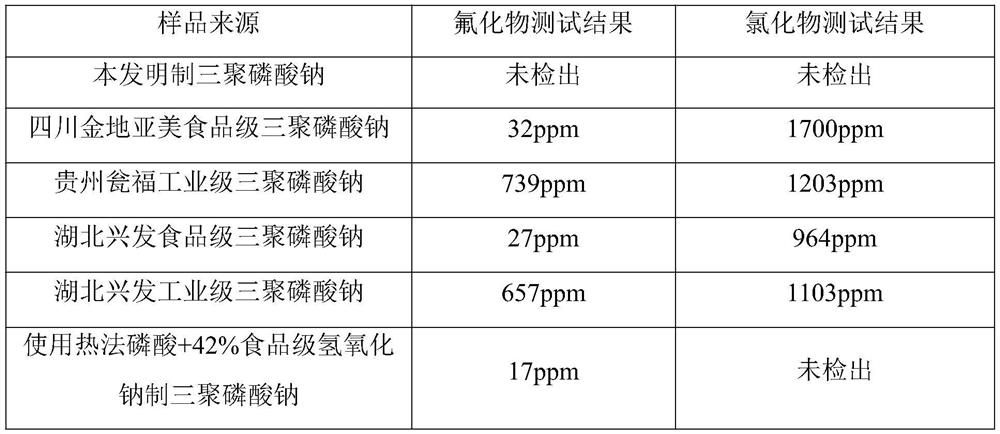

[0053] Fluoride test method: According to GB25566-2010 national food s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com